A kind of PVC plastic and preparation method thereof

A technology of plastics and raw materials to achieve the effects of improving mixing uniformity, good lubrication effect, and good long-term thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Among them, the lubricant uses SG-70s, plasticizers are triglycelets, and antioxidants use double [3- (3, 5-two-uncle-4 hydroxyl) phenyl) propionate.

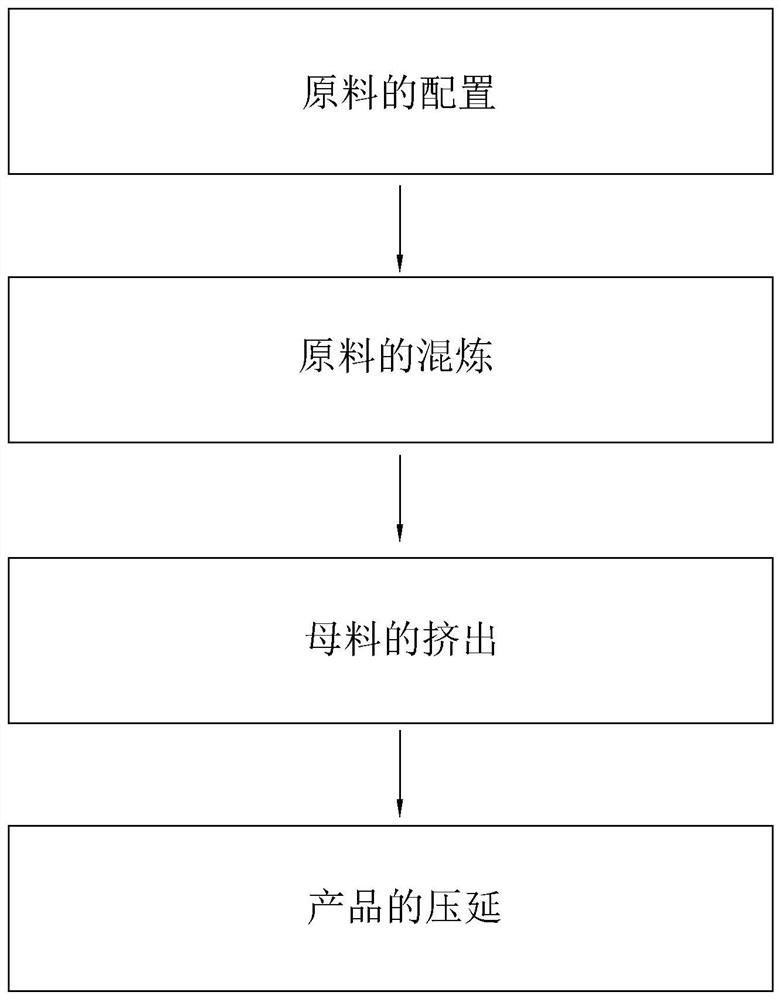

[0045] like figure 1 The preparation method of the PVC plastic includes the following steps:

[0046] S1, the configuration of raw materials: PVC, lubricant, plasticizer, antioxidant, 4-methoxybhenyl, calcium calcium, solid fatty acid zinc, epoxy soybean oil, magnesium aluminum water talcum powder according to the formulaObject for quantity and mix well;

[0047] S2, mixed raw materials: The raw materials that are mixed uniformly are mixed with dual rollers in 165 ° C for 20 minutes to get the mother material;

[0048] S3, the squeeze of the mother material: put the mother material into the extrusion machine for plasticizing the extrusion;

[0049] S4, the product's pressure extension: The plastic squeezed parent material is put into the plastic pressing machine, and the pressure is extended, cooled, and tailored in order to ...

Embodiment 2

[0052] Among them, the lubricant uses SG-70s, plasticizers are triglycelets, and antioxidants use double [3- (3, 5-two-uncle-4 hydroxyl) phenyl) propionate.

[0053] The preparation method of the PVC plastic includes the following steps:

[0054] S1, the configuration of raw materials: PVC, lubricant, plasticizer, antioxidant, 4-methoxybhenyl, calcium calcium, solid fatty acid zinc, epoxy soybean oil, magnesium aluminum water talcum powder according to the formulaObject for quantity and mix well;

[0055] S2, mixed raw materials: The raw materials that are mixed uniformly are mixed with dual rollers for 15 minutes in 170 ° C to get the mother material;

[0056] S3, the squeeze of the mother material: put the mother material into the extrusion machine for plasticizing the extrusion;

[0057] S4, the product's pressure extension: The plastic squeezed parent material is put into the plastic pressing machine, and the pressure is extended, cooled, and tailored in order to obtain the fi...

Embodiment 3

[0060] Among them, the lubricant uses SG-70s, plasticizers are triglycelets, and antioxidants use double [3- (3, 5-two-uncle-4 hydroxyl) phenyl) propionate.

[0061] The preparation method of the PVC plastic includes the following steps:

[0062] S1, the configuration of raw materials: PVC, lubricant, plasticizer, antioxidant, 4-methoxybhenyl, calcium calcium, solid fatty acid zinc, epoxy soybean oil, magnesium aluminum water talcum powder according to the formulaObject for quantity and mix well;

[0063] S2, mixed raw materials: The raw materials that are mixed uniformly are mixed with dual rollers for 15 minutes in 175 ° C to get the mother material;

[0064] S3, the squeeze of the mother material: put the mother material into the extrusion machine for plasticizing the extrusion;

[0065] S4, the product's pressure extension: The plastic squeezed parent material is put into the plastic pressing machine, and the pressure is extended, cooled, and tailored in order to obtain the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com