Special flame-retardant quenching oil for plate spring, and preparation method and application of special flame-retardant quenching oil

A quenching oil and flame retardant technology, applied in the field of heat treatment, can solve problems such as large smoke and fire, achieve high saturation, good oxidation resistance, and improve the production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

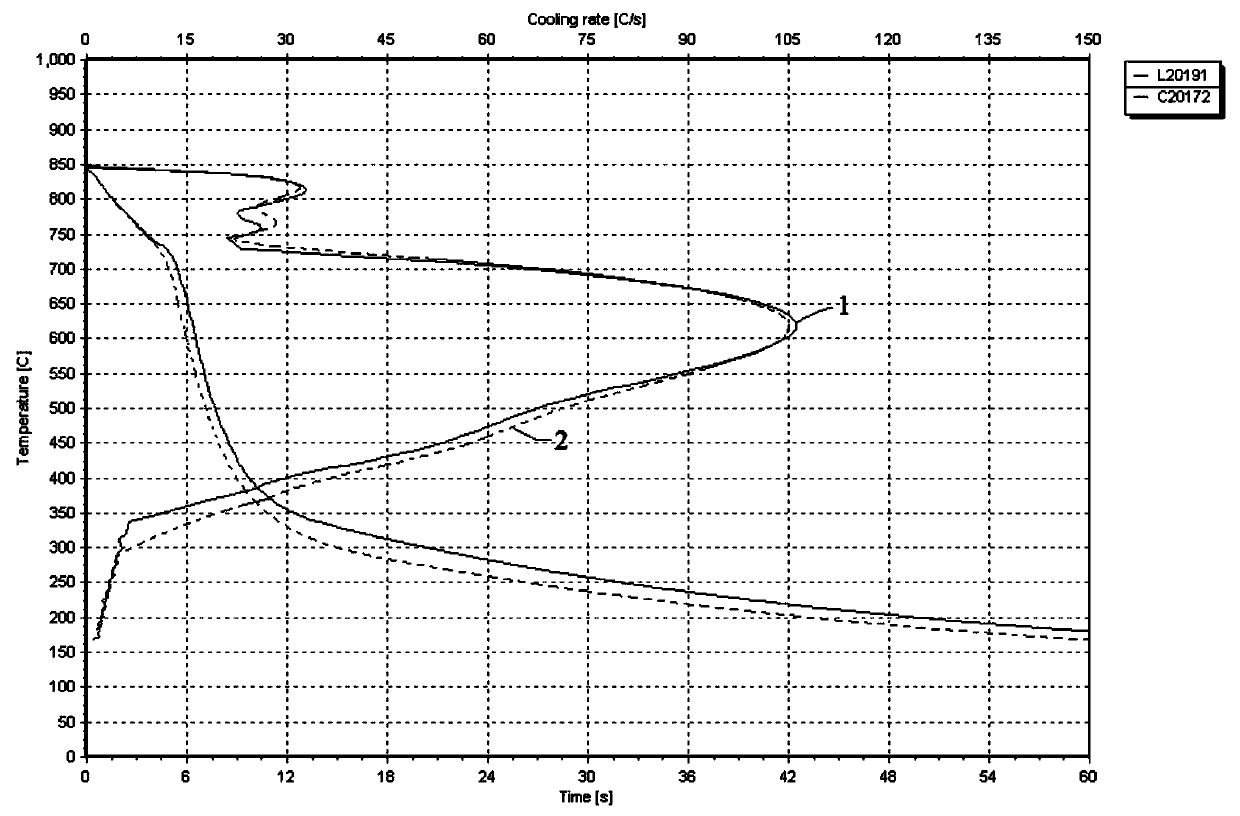

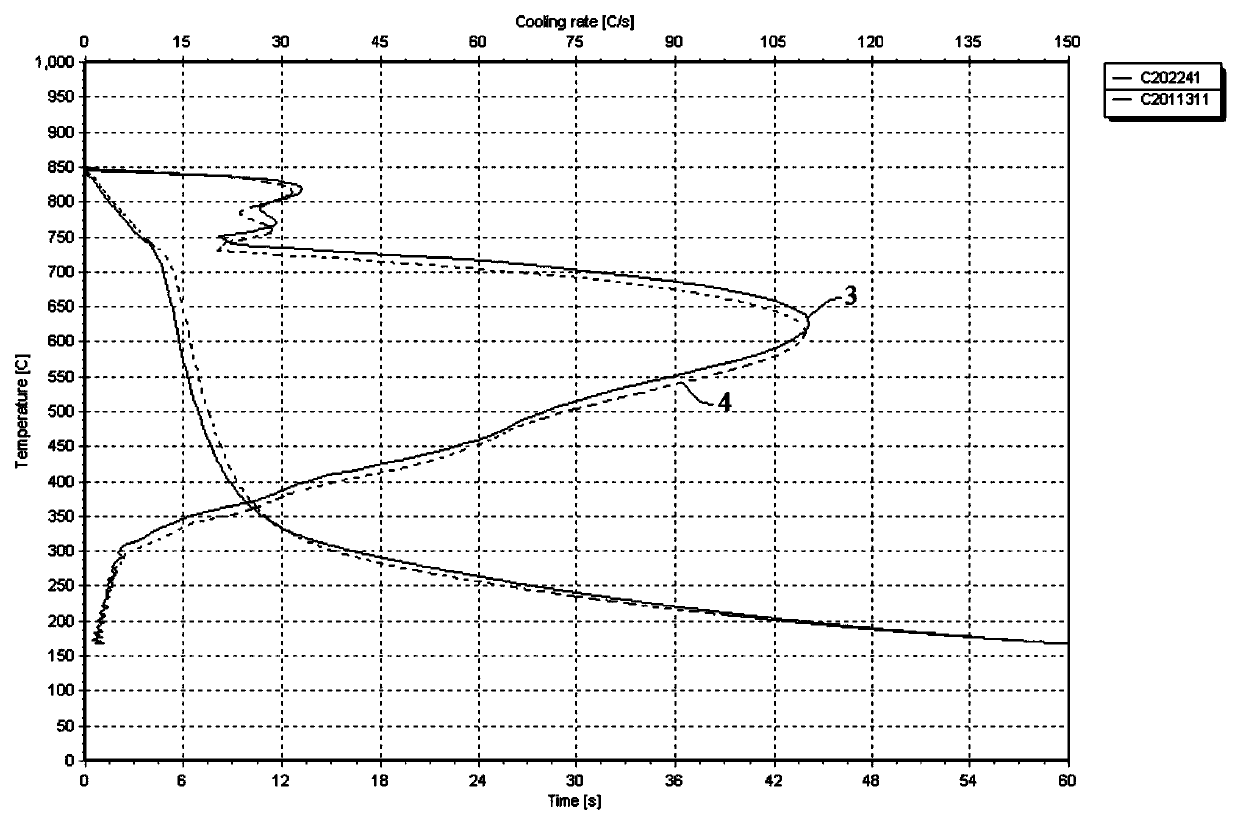

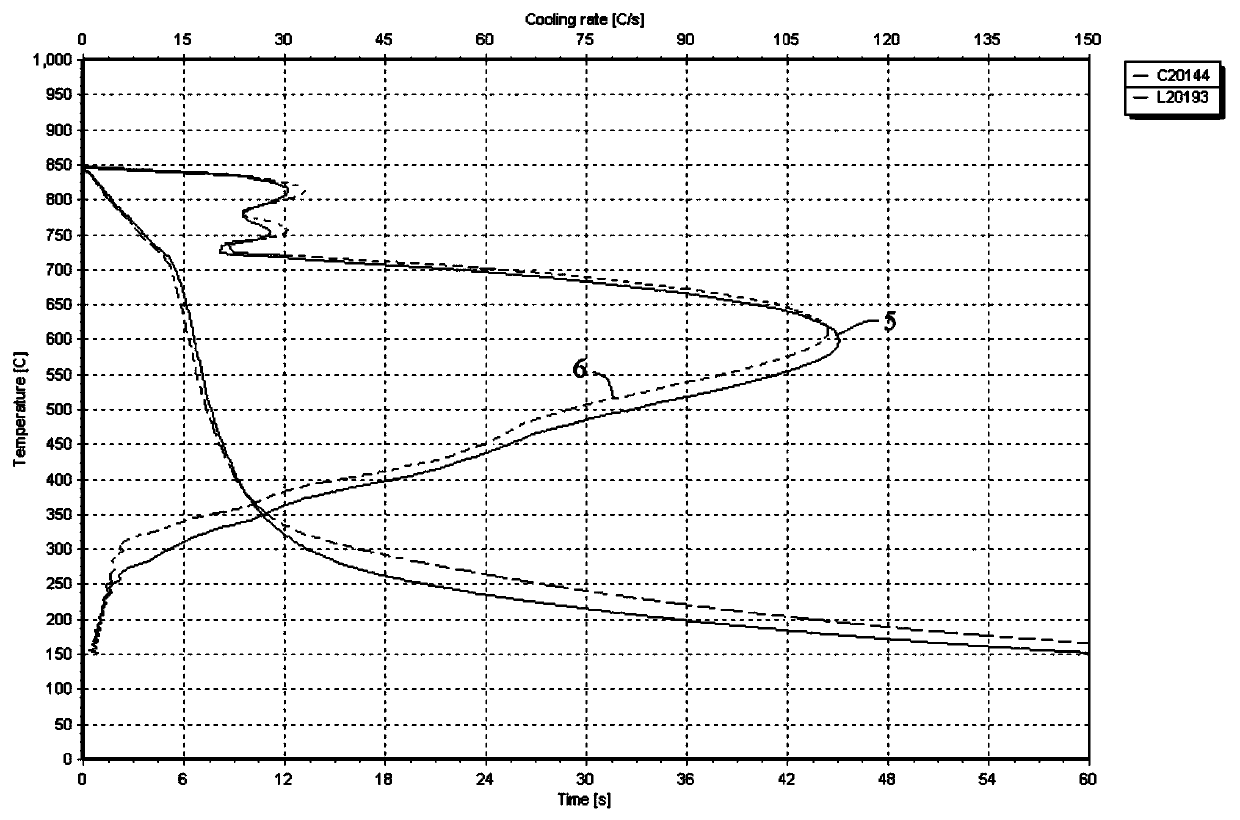

Image

Examples

Embodiment 1

[0042] A kind of leaf spring special flame retardant quenching oil of the present embodiment, its composition and the mass parts of each component are:

[0043] 50 parts of refined base oil;

[0044] 6 parts of refrigerant (the mixing mass ratio of polyisobutylene and polyol ester is 1:1);

[0045] Brightener (the mixing mass ratio of imidazoline oleate and methyl terpene resin is 2:1) 0.6 part;

[0046] 0.05 part of anti-oxidant (thionyl octyl zinc salt);

[0047] Surfactant (the mixing mass ratio of Span-80 and dioctyl sodium dibutyrate sulfonate is 1:1) 0.8 parts;

[0048] Flame retardant (the mixing mass ratio of dimethyl methylphosphonate and chlorinated paraffin is 2:1) 0.03 parts.

[0049] Among them, the refined base oil is primary or secondary hydrogenated base oil with a hydrogen content of 3-8%, and its kinematic viscosity is 14-25mm 2 / s, acid value ≤0.8mg KOH / g.

[0050] The preparation method of above-mentioned flame retardant quenching oil is as follows:

...

Embodiment 2

[0059] A kind of leaf spring special flame retardant quenching oil of the present embodiment, its composition and the mass parts of each component are:

[0060] 46 parts of refined base oil;

[0061] 8 parts of refrigerant (the mixing mass ratio of polyisobutylene and polyol ester is 2:1);

[0062] Brightener (the combined mass ratio of imidazoline oleate and methyl terpene resin is 2:1) 0.5 part;

[0063] 0.04 part of anti-oxidant (thionyl octyl zinc salt);

[0064] Surfactant (the mixing mass ratio of Span-80 and dioctyl sodium dibutyrate sulfonate is 1:1) 0.6 parts;

[0065] 0.02 parts of flame retardant (melamine cyanurate).

[0066] Among them, the refined base oil is primary or secondary hydrogenated base oil with a hydrogen content of 3-8%, and its kinematic viscosity is 14-25mm 2 / s, acid value ≤0.8mg KOH / g.

[0067] The preparation method of above-mentioned flame retardant quenching oil is as follows:

[0068] (1) Weigh 46 parts of refined base oil in proportion...

Embodiment 3

[0076] A kind of leaf spring special flame retardant quenching oil of the present embodiment, its composition and the mass parts of each component are:

[0077] 42 parts of refined base oil;

[0078] 10 parts of refrigerant (the mixing mass ratio of polyisobutylene and polyol ester is 3:2);

[0079] Brightener (the combined mass ratio of imidazoline oleate and methyl terpene resin is 2:1) 0.4 part;

[0080] 0.04 part of anti-oxidant (thionyl octyl zinc salt);

[0081] Surfactant (the mixing mass ratio of Span-80 and dioctyl sodium dibutyrate sulfonate is 1:1) 0.5 part;

[0082] 0.02 parts of flame retardant (resorcinol bis-diphenyl phosphate).

[0083] Among them, the refined base oil is primary or secondary hydrogenated base oil with a hydrogen content of 3-8%, and its kinematic viscosity is 14-25mm 2 / s, acid value ≤0.8mg KOH / g.

[0084] The preparation method of above-mentioned flame retardant quenching oil is as follows:

[0085] (1) Weigh 42 parts of refined base oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com