A copper-based shape memory alloy and its preparation method and application

A memory alloy, copper-based technology, applied in the field of memory alloys, can solve the problems of shape memory performance, service life not improved, memory alloy material change hysteresis, short service life and safety hazards, etc., to improve comprehensive performance and heat and cold Machining performance, improving the toughness of the alloy, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a method for preparing a copper-based shape memory alloy described in the above technical solution, comprising the following steps:

[0040] (1) carrying out eutectic melting of zinc and tin to obtain the first alloy liquid;

[0041] (2) mixing the manganese-copper master alloy and the boron-copper master alloy with the first alloy liquid described in step (1), and carrying out the first melting to obtain the second alloy liquid;

[0042] (3) aluminum, CuP14 phosphorus copper deoxidizer are mixed with the second alloy liquid described in step (2), carry out deoxidation reaction, obtain the 3rd alloy liquid;

[0043] (4) mixing the refining agent with the third alloy liquid described in step (3), and refining to obtain the fourth alloy liquid;

[0044] (5) mixing the LaCe mixed rare earth with the fourth alloy liquid described in step (4), and performing the second melting to obtain the fifth alloy liquid;

[0045] (6) homogenizing the fi...

Embodiment 1~6

[0065] In terms of 100% mass content, the chemical composition of the copper-based shape memory alloy base material of Examples 1-6 is shown in Table 1; the preparation method of the copper-based shape memory alloy base material is:

[0066] Preheat the natural gas copper melting furnace to 600°C, add electrolytic copper and retorted fruit charcoal particles, and heat up to fully melt; raise the temperature in the furnace to 1080°C, add 0# zinc and refined tin for eutectic melting, and obtain the first alloy liquid;

[0067] Control the temperature in the furnace to be 1100°C, add manganese-copper master alloy Cu75%Mn25% (mass fraction) and boron-copper master alloy Cu95%B5% (mass fraction), and perform the first melting to obtain the second alloy liquid;

[0068] Control the temperature in the furnace to 1120°C, add A00 aluminum, stir fully, add CuP14 phosphorus copper for deoxidation, stir, and carry out deoxidation reaction to obtain the third alloy liquid;

[0069] Control...

Embodiment 7~12

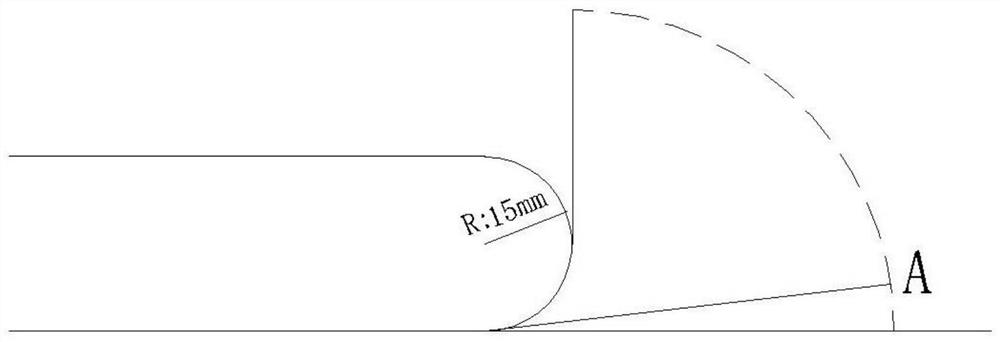

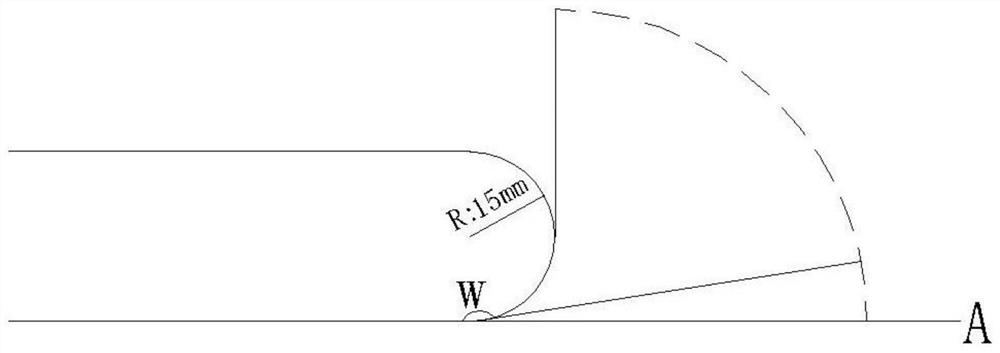

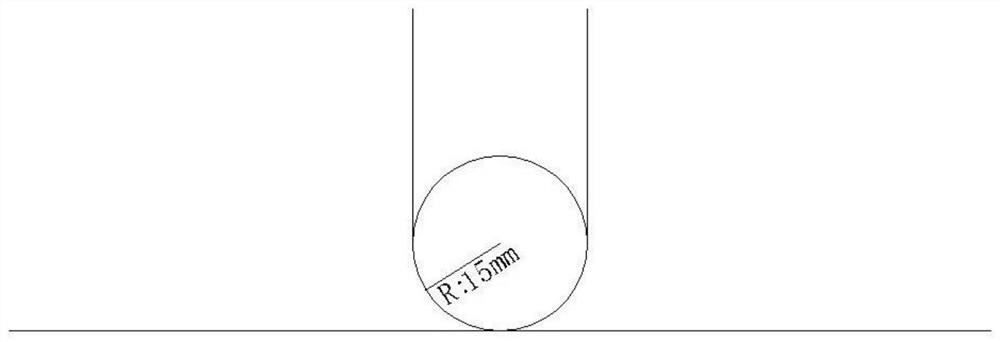

[0093] The copper-based shape memory alloy base material prepared in Examples 1-6 is subjected to cold and hot processing to obtain the copper-based shape memory alloy in Examples 7-12; wherein, the copper-based shape memory alloy base material prepared in Example 1 is Carry out cold and hot processing to obtain the copper-based shape memory alloy of embodiment 7; The copper-based shape memory alloy parent material prepared in embodiment 2 is carried out to obtain the copper-based shape memory alloy of embodiment 8; and so on; The specific method of hot and cold processing is as follows:

[0094] Place the copper-based shape memory alloy base material of Examples 1 to 6 in a box-type resistance furnace, and uniformly anneal for 12 hours at 850°C, then cool to room temperature with the furnace temperature, and then heat the alloy to 850°C again, at a constant temperature Homogenizing annealing for 8 hours, and then water cooling at 30°C to obtain a copper-based shape memory all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com