A kind of biochar with heavy metal adsorption and its preparation method and application

A technology for adsorbing heavy metals and biochar, applied in the direction of carbon preparation/purification, non-metallic elements, chemical instruments and methods, etc., which can solve the problems of complex treatment process, many steps, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

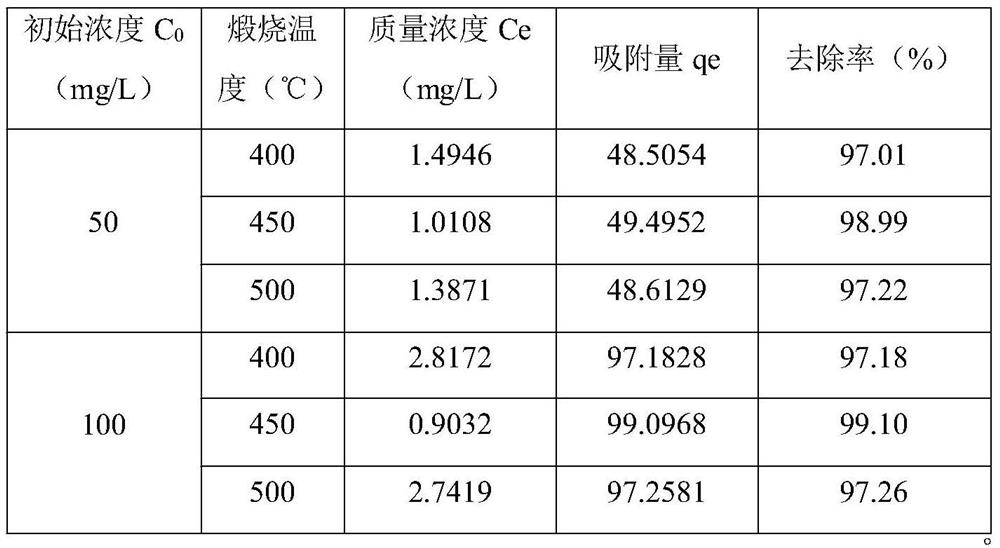

[0093] Embodiment 7 Copper ion adsorption experiment

[0094] Weigh respectively 0.05g of the samples obtained from the compatibility of the above examples 1 to 6, and place them in a 500ml wide-mouth conical flask. In each sample, add CU with a concentration of 100mg / L 2+ solution. Place the Erlenmeyer flask in a double-layer constant temperature shaker at (25±5)°C, shake at a speed of 150r / min for 12h, take out a 0.45μm microporous filter membrane, and measure Cu in the filtrate with a flame atomic absorption spectrometer 2+ , and calculate the combined materials of different examples for the Cu in the solution 2+ adsorption capacity and removal rate.

[0095] As can be seen from Table 7, the composite adsorption materials of different component ratios have significantly different adsorption capacities to copper ions; 2+ The adsorption is also the strongest, followed by Example 6, which is better than other groups, showing that the composite adsorption material composed o...

Embodiment 8

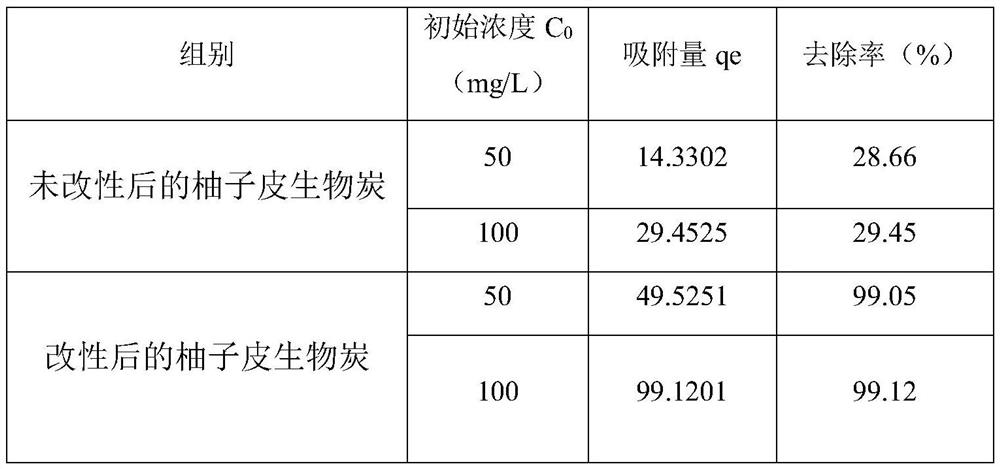

[0098] Embodiment 8 nickel ion adsorption experiment

[0099] Take respectively 0.05g of the samples obtained by the compatibility of the above examples 1 to 6, place them in a 500ml wide-mouth conical flask, and in each sample, add a concentration of 100mg / L of Ni 2+ solution. Place the Erlenmeyer flask in a double-layer constant temperature shaker at (25±5)°C, shake at a speed of 150r / min for 12h, take out a 0.45μm microporous filter membrane, and use a flame atomic absorption spectrometer to measure Ni in the filtrate 2+ , and calculate the combined materials of different examples for the Ni in the solution 2+ adsorption capacity and removal rate.

[0100] As can be seen from Table 8, the composite adsorption material of different component proportions is obviously different to the adsorption capacity of nickel ion; Embodiment 1 of the present invention is to Ni ion 2+ The adsorption effect is also the strongest, which is better than other groups, indicating that the compo...

Embodiment 9

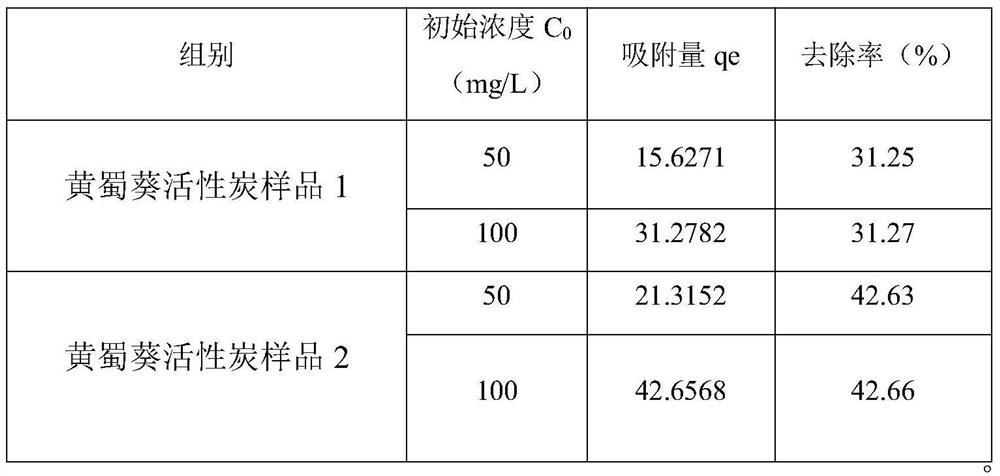

[0103] Embodiment 9 Chromium ion adsorption experiment

[0104] Take by weighing each 0.05g of the samples obtained by the compatibility of the above examples 1 to 6 respectively, place them in a 500ml wide-mouth conical flask, and add a concentration of 100mg / L of Cd in each sample. 2+ solution. Place the Erlenmeyer flask in a double-layer constant temperature shaker at (25±5)°C, shake at a speed of 150r / min for 12h, take out a 0.45μm microporous filter membrane, and measure the Cd in the filtrate with a flame atomic absorption spectrometer 2+ , and calculate the combined materials of different examples for the Cd in the solution 2+ adsorption capacity and removal rate.

[0105] As can be seen from Table 9, the composite adsorbents of different component ratios have significantly different adsorption capacities to chromium ions; 2+ The adsorption effect is better than that of other groups, indicating that the composite adsorption material composed of the raw materials in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com