Hydrocracking catalyst as well as preparation method and application thereof

A hydrocracking and catalyst technology, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of not meeting industrial requirements, poor catalyst activity, etc., so as to improve the effective utilization rate and reduce the amount of strong acid , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of hydrocracking catalyst carrier

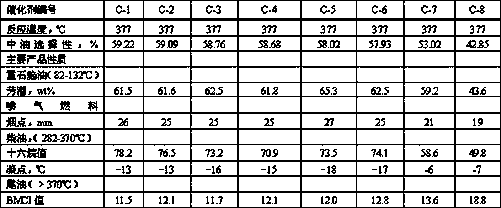

[0032] Put 20gY molecular sieve, 8gSAPO-34 molecular sieve, 80g alumina, and 4.2g microcrystalline cellulose into the rolling machine for rolling. After rolling for 20 minutes, add guar gum (0.3%) and nitric acid (2.5%) The aqueous solution is rolled into a paste and extruded. The extruded strips are dried at 120°C for 3 hours and calcined at 500°C for 3 hours to obtain the carrier Z1.

[0033] (2) Catalyst preparation

[0034] The carrier Z1 is impregnated with an equal volume of impregnating solution containing Mo, Ni, P and bis-[3-(triethoxysilyl)propyl]-tetrasulfide, dimethylamide and water, bis-[3-(tri The molar ratio of ethoxysilane)propyl]-tetrasulfide to the Mo content of the final catalyst is 0.05:1, dried at 120°C for 3h, and calcined at 390°C for 2 hours, the finally obtained catalyst is denoted as C-1. Table 1.

Embodiment 2

[0036] (1) Preparation of hydrocracking catalyst carrier

[0037] Put 25gY molecular sieve, 6gSAPO-34 molecular sieve, 70g of alumina, and 2.8g of microcrystalline cellulose into the rolling machine for rolling. After rolling for 25 minutes, add guar gum (0.4%) and nitric acid (2.5%). aqueous solution, rolled into a paste, and extruded, the extruded strips were dried at 120°C for 3 hours, and roasted at 550°C for 3 hours to obtain the carrier Z2.

[0038] (2) Catalyst preparation

[0039] Impregnate carrier Z2, N-aminoethyl-3-aminopropyl, with equal volumes of impregnating solution containing Mo, Ni, P and N-aminoethyl-3-aminopropylmethyldimethoxysilane, glycerol and water The molar ratio of methyldimethoxysilane to the Mo content of the final catalyst was 0.08:1, dried at 120°C for 3 hours, and calcined at 410°C for 2 hours. The finally obtained catalyst was designated as C-2.

Embodiment 3

[0041] (1) Preparation of hydrocracking catalyst carrier

[0042] Put 25gY molecular sieve, 7gSAPO-34 molecular sieve, 75g aluminum oxide, and 2.0g microcrystalline cellulose into the rolling machine for rolling. After rolling for 30 minutes, add guar gum (0.4%) and acetic acid (2.8%) The aqueous solution was rolled into a paste and extruded. The extruded strips were dried at 120°C for 3 hours and calcined at 560°C for 3 hours to obtain carrier Z3.

[0043] (2) Catalyst preparation

[0044] Impregnation carrier Z3 is impregnated with equal volumes of impregnating liquid containing Mo, Ni, P and methyltriacetoxysilane, dimethyl sulfoxide and water, and the molar ratio of methyltriacetoxysilane and final catalyst Mo content is 0.08: 1. After drying at 120°C for 3 hours and calcining at 380°C for 2 hours, the catalyst finally obtained is designated as C-3. Catalyst properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com