Coarse slime separation diaphragm jig and arrangement mode thereof

A jig and coarse coal slime technology, applied in the field of jigs, can solve problems such as inability to sort at one time, difficulty in recycling, poor coal separation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

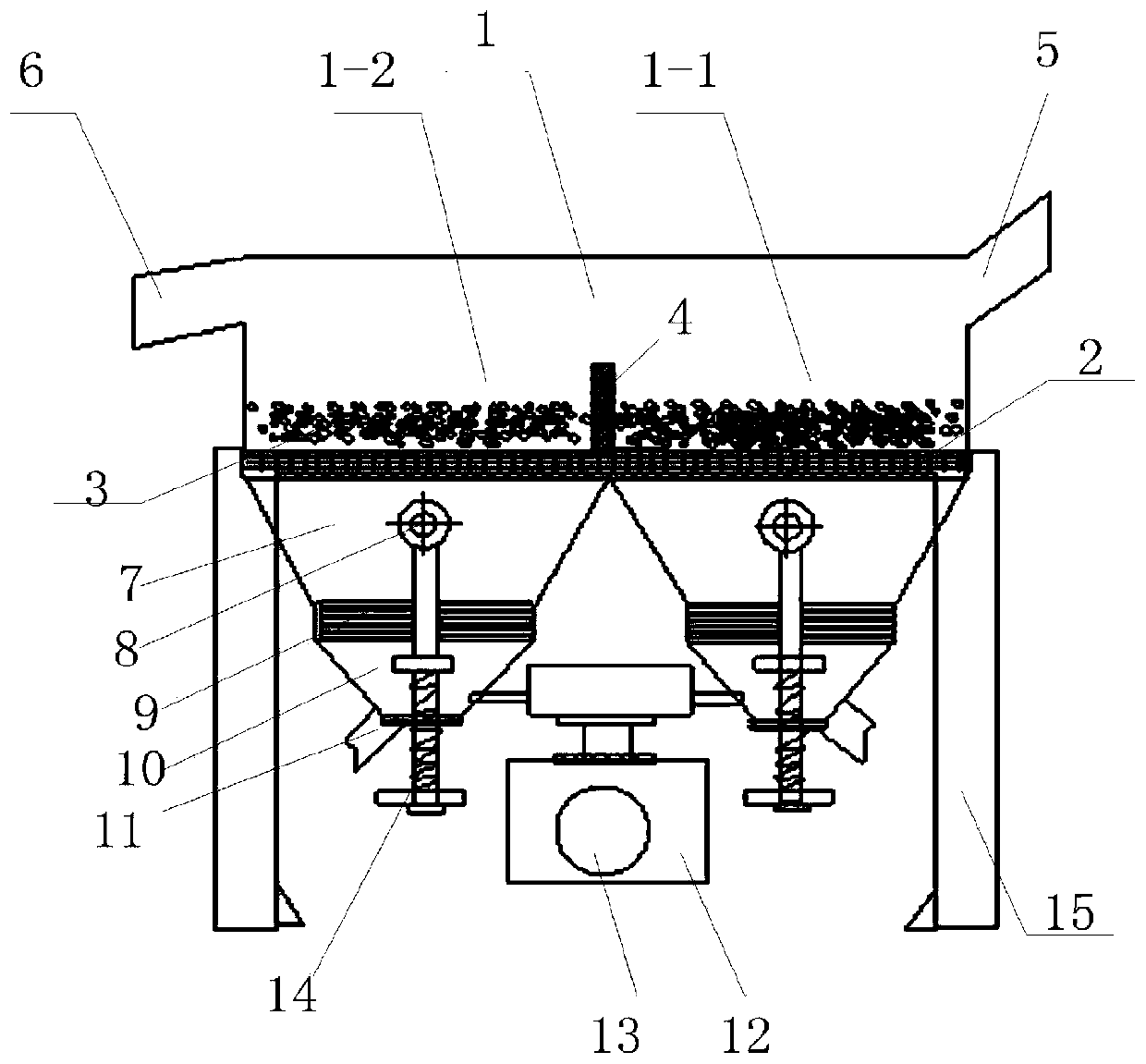

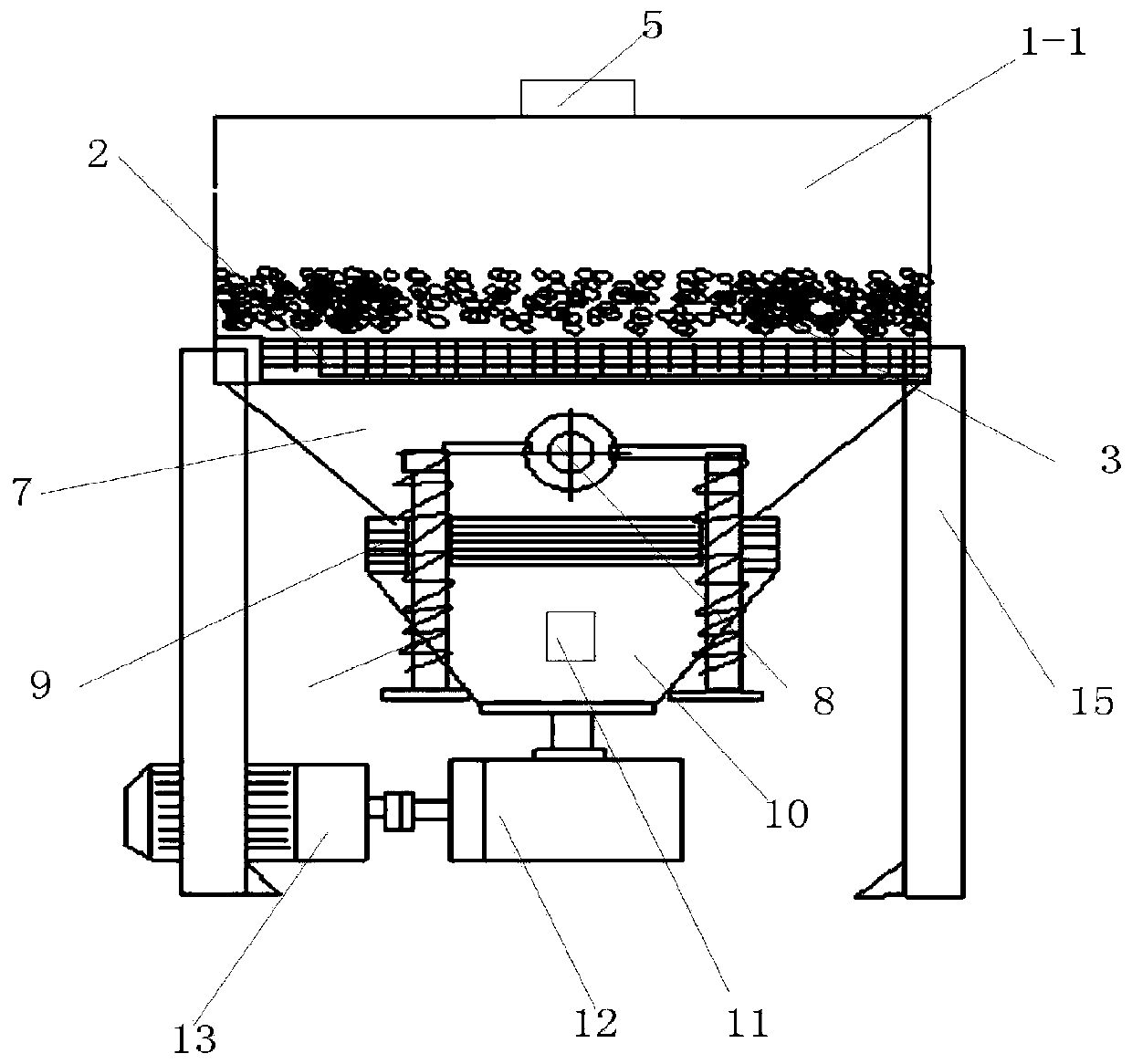

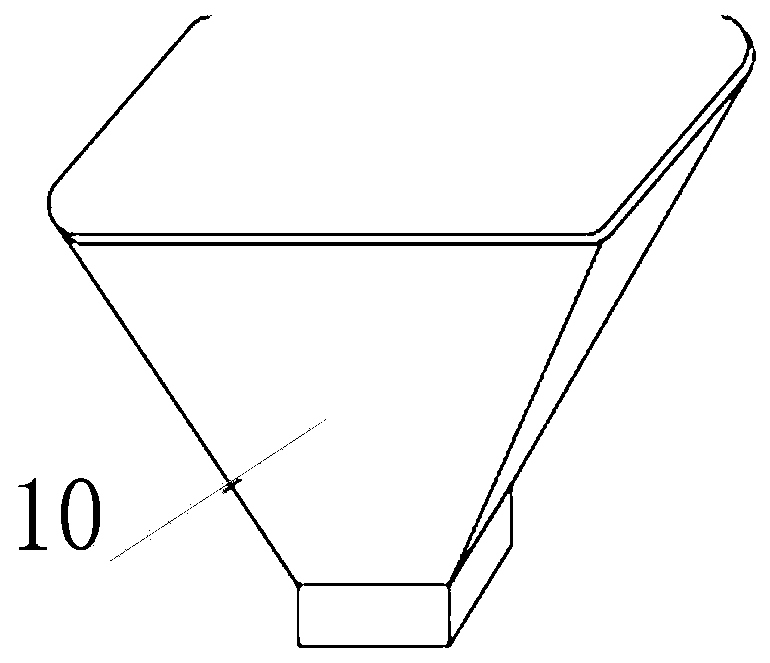

[0037] See Figure 1-Figure 4The purpose of the embodiments of the present invention is to provide a coarse coal slime with a wide range of sorting density and particle size, strong adaptability to coal quality, simple structure, easy operation, low cost and high sorting accuracy, which can be widely used in industrial production. Sorting diaphragm jig. Specifically, the embodiment of the present invention provides a coarse slime separation diaphragm jig machine comprising: a jig chamber 1, a stainless steel sieve plate 2, an artificial bed without external discharge 3, a partition plate 4, a raw material inlet 5, Light product discharge port 6, two upper rectangular cones 7, two lower rectangular cones 10, two rectangular rubber diaphragms 9, two heavy product discharge ports 11, two heavy product discharge port valves, two Water supply valve 8, frame 15, speed regulating motor 13, cam box 12, water inlet pipeline, washing water pipeline, and top water pipeline.

[0038] Th...

Embodiment 2

[0066] On the basis of the above Embodiment 1, the use method of the coarse slime separation diaphragm jig provided by the present invention is introduced.

[0067] 1. The stainless steel sieve plate 2 lays a permanent pebble-free artificial bed 3, with a thickness of 400-600 mm, divided into a bottom layer, a middle layer and an upper layer; 2.5-3.3t / m3; the thickness of the middle layer is 200 mm, the particle size of the laying bed stone is 7-8 mm, and the density is 2.5-2.8t / m3; the thickness of the upper layer is 200 mm, and the particle size of the laying bed stone is 5-6 mm, The density is 2.2-2.5t / m3.

[0068] 2. On the side of the diaphragm jig machine, the heavy product discharge port 11 at the bottom of the lower rectangular cone 10 installed under the first chamber 1-1 is used as the gangue discharge port, and the other heavy product discharge port 11 is used as the medium coal discharge port, respectively. Close the heavy product discharge port valves arranged on...

Embodiment 3

[0078] On the basis of the above Embodiment 1 and Embodiment 2, the embodiment of the present invention further illustrates the solution provided by the embodiment of the present invention by taking the coarse coal slime with 55% ash content and particle size of 0.1-2 mm as an example.

[0079] Step 1: Close the two heavy product discharge ports 11 valves at the bottom of the jig cone, and prepare for the dehydration of coal gangue in the first room 1-1 of the jig and 1-2 in the second room at the bottom of the jig cone. Shaker.

[0080] Step 2: Start the clean water pump to transport clean water to the rectangular cone bucket 7 on the jig and the feed water valve 8 and the jig raw material inlet 5. The clean water submerges the 3100mm artificial bed without external drainage, and the clean coal light product discharge port 6 overflows prevail.

[0081] Step 3: The coarse coal slime with ash content of 55% and particle size of 0.1-2 mm is fed into the feed inlet 5 of the jig ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com