Metal modified silica sol for synthesizing SAPO-34 molecular sieve and preparation method of metal modified silica sol

A metal modification, silica sol technology, applied in the field of metal modified silica sol, small particle size metal modified silica sol, can solve the problem of particle size reduction and specific surface area, to achieve increased specific surface area, large specific surface area, The effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A kind of metal-modified silica sol for synthesizing SAPO-34 molecular sieve, preparation method comprises the following steps:

[0038] S1. Mix silicon powder with a molar number of 3.5 to 6.5, a particle size of not higher than 50 μm, and a purity of not lower than 99%, and deionized water with a molar number of 14 to 52, stir, and activate at 45 to 65°C for 15 minutes to 1h;

[0039] S2, adding 0.025-0.30 moles of a basic catalyst, feeding at a temperature of 50-65°C, and reacting at 70-95°C for 5-8 hours to obtain a silica sol seed solution;

[0040] S3. Mix and stir the silica sol seed solution, deionized water, 0.025-0.05 moles of metal salt solution, and 0.025-0.05 moles of basic catalyst at 65-90°C, and react at 70-95°C for 2-5 hours After that, the modified silica sol solution is obtained;

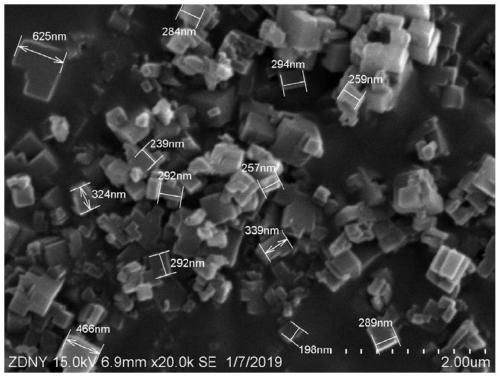

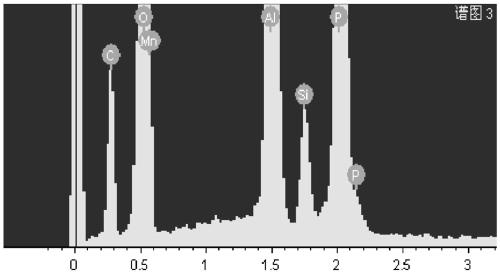

[0041] S4. After stilling, precipitation and suction filtration, a metal-modified silica sol product with a particle size of 4-10 nm is obtained.

[0042] In the above p...

Embodiment 1

[0046] Add 500ml of deionized water to a 2L round bottom flask, add 100g of metal silicon powder under stirring, and activate at 45°C for 15min in a water bath. When the temperature rises to 65°C, slowly add an alkaline catalyst solution made of 1g of sodium hydroxide and 100ml of deionized water to the activated solution one by one. After the reaction exotherm is stable, rise to 80°C and react for 5h to obtain silica sol seeds solution.

[0047] Dissolve 1g of sodium hydroxide in 100ml of deionized water to make an alkaline catalyst solution, and heat it to 80°C, and dissolve 15g of Zn(NO 3 )·6H 2 O was dissolved in 100ml deionized water to make a metal salt solution; after mixing the two with the silica sol seed solution prepared in the previous step, react at 80°C for 2 hours under stirring.

[0048]After static precipitation and suction filtration to remove a small amount of unreacted metal silicon powder, a small particle size metal modified silica sol product is obtain...

Embodiment 2

[0050] Add 700ml of deionized water into a 2L round bottom flask, add 120g of metal silicon powder under stirring, and activate at 50°C for 15min in a water bath. When the temperature rises to 65°C, slowly add an alkaline catalyst solution made of 2g of sodium hydroxide and 100ml of deionized water to the activated solution one by one. After the reaction exotherm is stable, rise to 85°C and react for 5h to obtain silica sol seeds solution.

[0051] Dissolve 1g of sodium hydroxide in 100ml of deionized water to make an alkaline catalyst solution, and heat to 85°C, 15g of Zn(NO 3 )·6H 2 O was dissolved in 100ml of deionized water to make a metal salt solution; after mixing the two with the silica sol seed solution prepared in the previous step, react at 85°C for 3 hours under stirring.

[0052] After static precipitation and suction filtration to remove a small amount of unreacted metal silicon powder, a small particle size metal modified silica sol product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com