Carbon cloth electrode surface electrochemical oxidation method and heavy metal adsorption method

A carbon cloth electrode and electrochemical technology, applied in the field of chemical oxidation on the surface of carbon cloth electrodes, can solve the problems of limited active sites on the surface of carbon cloth electrodes, destroying electrode conductivity, etc. The effect of strong controllability of activity and oxidation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

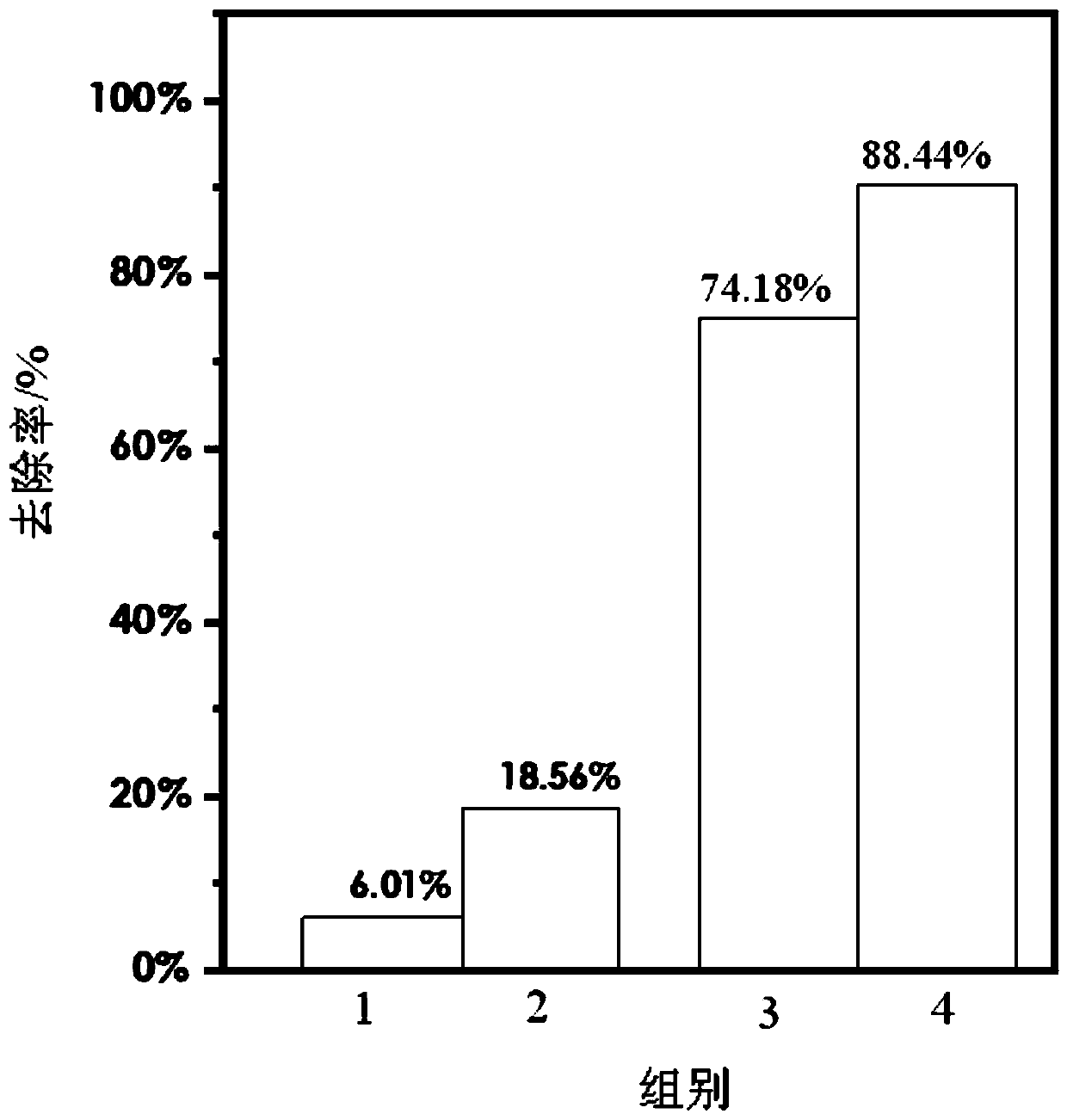

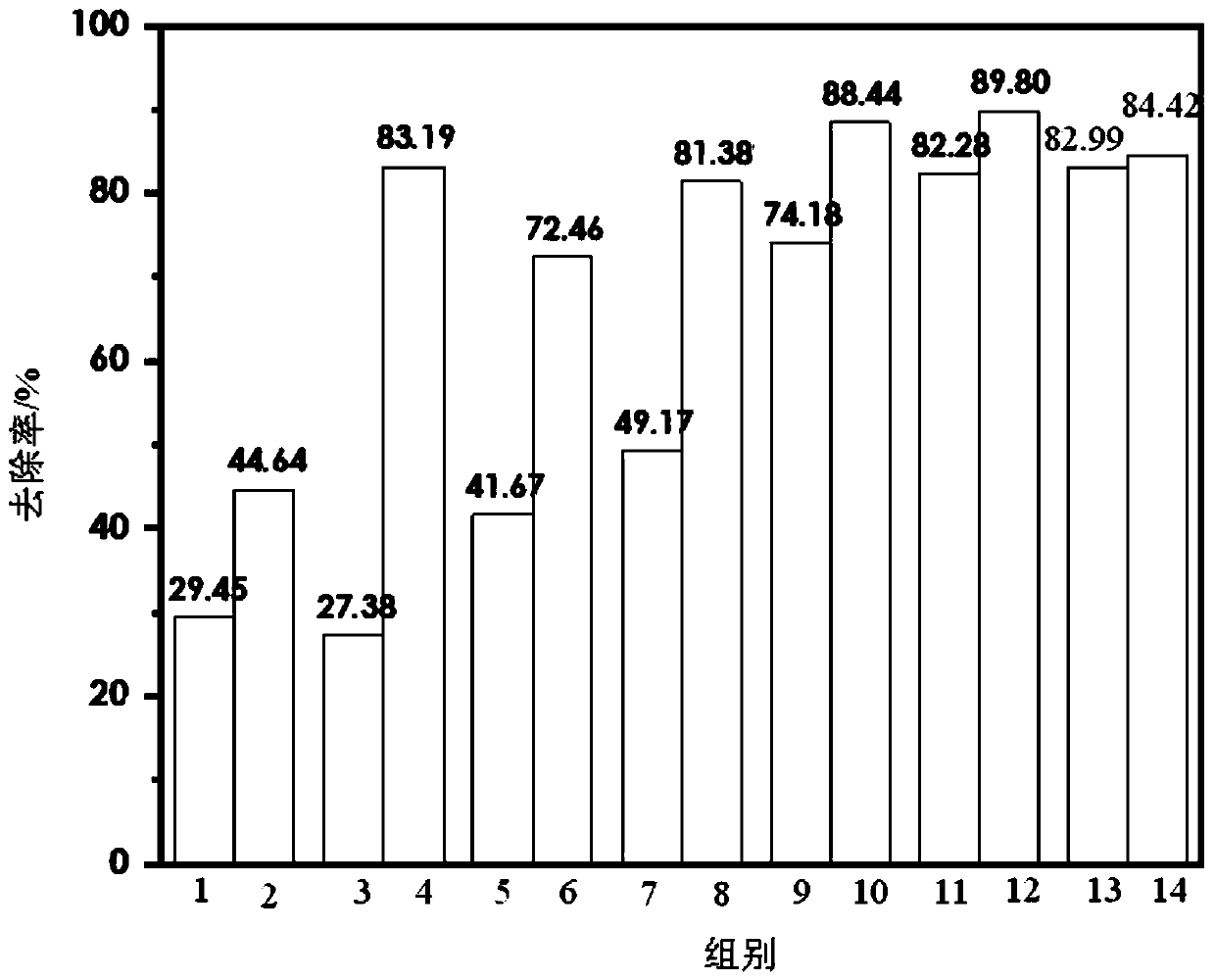

[0017] Embodiment 1: This embodiment is a method for electrochemical oxidation of the surface of a carbon cloth electrode, which is specifically carried out according to the following steps:

[0018] 1. Pretreatment of carbon cloth: Put the carbon cloth into acetone and ultrasonically soak for 24h~25h to remove the organic matter on the surface of the carbon cloth, then put it into absolute ethanol and ultrasonically soak for 24h~25h to remove the residual acetone on the carbon cloth. Then soak in deionized water for 24h to 25h to remove the absolute ethanol on the surface of the carbon cloth, and finally dry at 70°C to 75°C to obtain a pretreated carbon cloth;

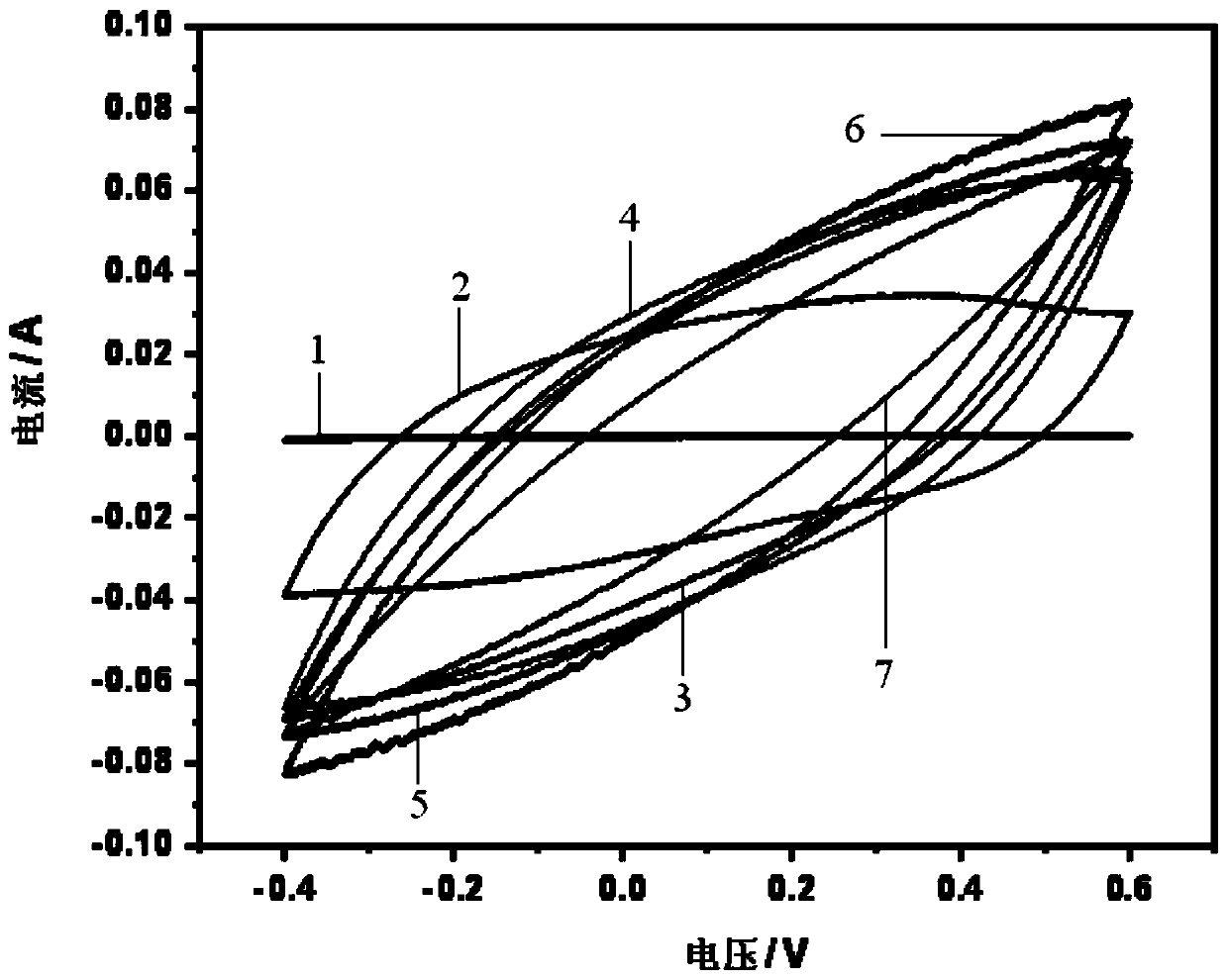

[0019] 2. Electrochemical oxidation: a three-electrode system is used, the electrolyte solution is sulfuric acid aqueous solution, the carbon cloth pretreated in step 1 is used as the working electrode, the platinum mesh is used as the counter electrode, and the saturated Ag / AgCl is used as the reference electrode, and...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, dry at 70° C. to obtain pretreated carbon cloth. Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the scan rate in step 2 is 20 mV / s. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com