Degradable food packaging bag and preparation method thereof

A technology for packaging bags and food, applied in the field of degradable food packaging bags and their preparation, can solve the problems of water resistance, low strength, unpracticality, and no thermoplasticity of packaging bags, and achieves improved mechanical properties and barrier properties. The effect of improving compatibility and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

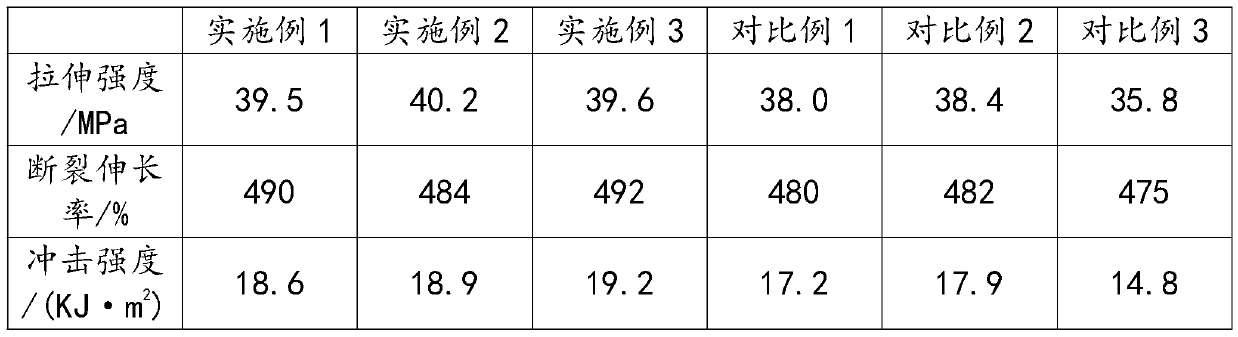

Examples

preparation example Construction

[0041] The preparation method of this packing bag, comprises the steps:

[0042] Step S1, drying the modified PBAT in a vacuum oven at 80°C for 4-5 hours;

[0043] Step S2, after uniformly mixing the dried modified PBAT, reinforcing filler and plasticizer, extruding and granulating through a twin-screw granulator to obtain plastic granules;

[0044] Step S3, the plastic particles are blown into a packaging film by a film blowing machine, and the packaging film is cut and bag-made to obtain the packaging bag.

Embodiment 1

[0046] A degradable food packaging bag, made of the following raw materials in parts by weight: 60 parts of modified PBAT, 3 parts of reinforcing filler, and 0.8 parts of plasticizer;

[0047] The packaging bag is made by the following steps:

[0048] Step S1, drying the modified PBAT in a vacuum oven at 80°C for 4 hours;

[0049] Step S2, after uniformly mixing the dried modified PBAT, reinforcing filler and plasticizer, extruding and granulating through a twin-screw granulator to obtain plastic granules;

[0050] Step S3, the plastic particles are blown into a packaging film by a film blowing machine, and the packaging film is cut and bag-made to obtain the packaging bag.

Embodiment 2

[0052] A degradable food packaging bag, made of the following raw materials in parts by weight: 65 parts of modified PBAT, 3.5 parts of reinforcing filler, and 0.9 parts of plasticizer;

[0053] The packaging bag is made by the following steps:

[0054] Step S1, drying the modified PBAT in a vacuum oven at 80°C for 4.5 hours;

[0055] Step S2, after uniformly mixing the dried modified PBAT, reinforcing filler and plasticizer, extruding and granulating through a twin-screw granulator to obtain plastic granules;

[0056] Step S3, the plastic particles are blown into a packaging film by a film blowing machine, and the packaging film is cut and bag-made to obtain the packaging bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com