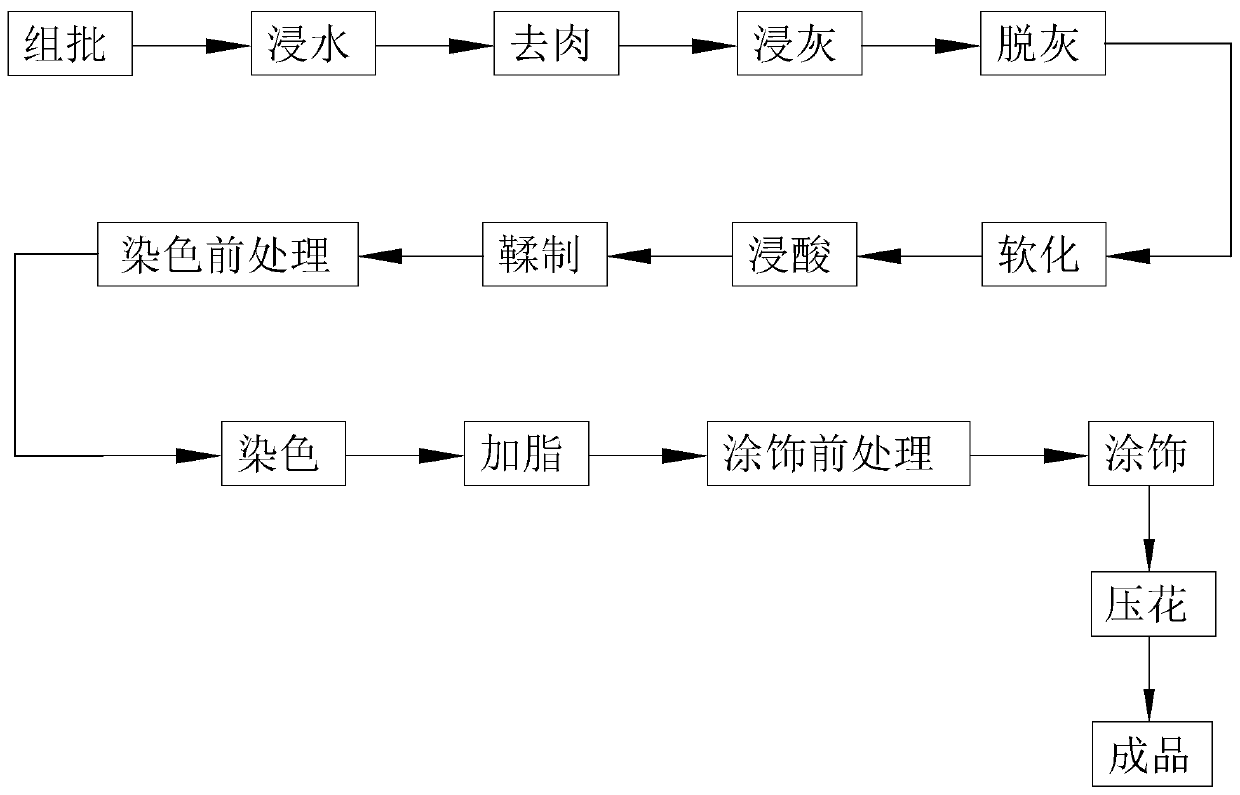

Production process of genuine leather

A production process and leather technology, applied in the field of leather leather production technology, can solve problems such as affecting the use of leather, reducing leather quality, and easy cracking of the coating, achieving the effects of not easy cracking, improving leather quality, and good coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

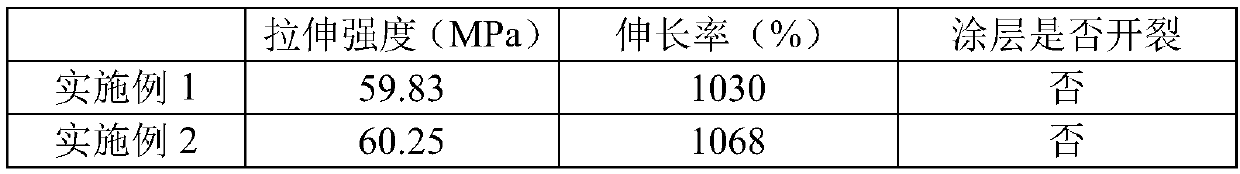

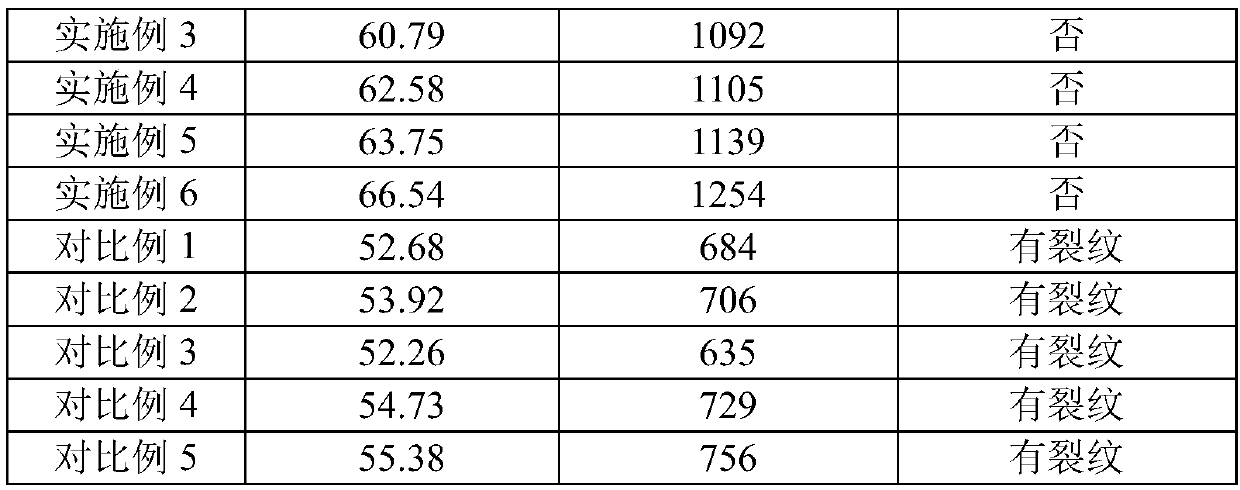

Examples

Embodiment 1

[0047] A production process of genuine leather, specifically including the following steps:

[0048] Step 1. Batching: Put the original skins with similar width and thickness in the same drum for processing, the original skin weight is 10kg;

[0049] Step 2. Water soaking: add water to the drum to soak the raw hides according to the liquid ratio of 1.2, and add 25% ammonia water, adjust the pH of the water in the drum to 7.5, the immersion temperature to 25°C, and the soaking time to 25h;

[0050] Step 3. Meat removal: Take out the raw skin that has been soaked in water, and use a meat removal machine to remove the hair on the surface of the raw skin and the meat on the raw skin;

[0051] Step 4. Liming: The raw hides after meat removal are placed in a rotating drum and soaked in sodium hydroxide solution with pH 11, liquid ratio is 1.2, soaking temperature is 25°C, and soaking time is 25h;

[0052] Step 5. Deliming: After the liming is finished, the sodium hydroxide solution in step 4 ...

Embodiment 2

[0064] A production process of genuine leather, specifically including the following steps:

[0065] Step 1. Batching: Put the original skins with similar width and thickness in the same drum for processing, the original skin weight is 10kg;

[0066] Step 2. Water soaking: add water to the drum according to the liquid ratio of 1.5 to soak the original hides, and add 25% ammonia water, adjust the pH to 8.5, the soaking temperature to 28°C, and the soaking time to 15h;

[0067] Step 3. Meat removal: Take out the raw skin that has been soaked in water, and use a meat removal machine to remove the hair on the surface of the raw skin and the meat on the raw skin;

[0068] Step 4. Liming: The raw hides after meat removal are placed in a rotating drum and immersed in a calcium hydroxide solution with a pH of 12, the liquid ratio is 1.5, the immersion temperature is 28°C, and the immersion time is 20h;

[0069] Step 5. Deliming: After the liming is finished, the calcium hydroxide solution in st...

Embodiment 3

[0081] A production process of genuine leather, specifically including the following steps:

[0082] Step 1. Batching: Put the original skins with similar width and thickness in the same drum for processing, the original skin weight is 10kg;

[0083] Step 2. Water soaking: Add water to the drum to soak the raw hides according to the liquid ratio of 1.4, and add 25% ammonia water, adjust the pH to 8, the soaking temperature is 27°C, and the soaking time is 21h;

[0084] Step 3. Meat removal: Take out the raw skin that has been soaked in water, and use a meat removal machine to remove the hair on the surface of the raw skin and the meat on the raw skin;

[0085] Step 4. Liming: The raw hides after meat removal are placed in a rotating drum and soaked in calcium hydroxide solution with pH 12, the liquid ratio is 1.4, the soaking temperature is 28°C, and the soaking time is 20h;

[0086] Step 5. Deliming: After the liming is finished, drain the calcium hydroxide solution in step 4, add 30°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com