Rust remover and preparation method and application thereof

A technology of rust remover and purity, applied in the field of rust remover and its preparation, can solve the problems of slow rust removal rate, high operation risk, and many surface residues, and achieve moderate rust removal rate, simple and safe operation, and long storage time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

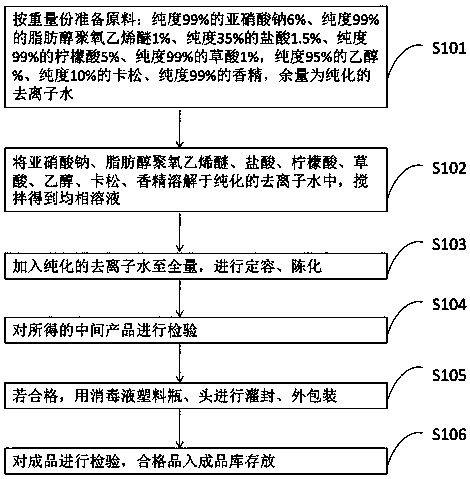

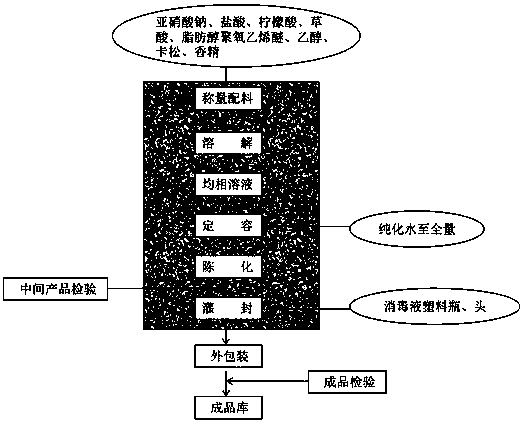

[0026] Such as figure 1 Shown, the preparation method of the rust remover that the embodiment of the present invention provides comprises the following steps:

[0027] S101: Prepare raw materials in parts by weight: 6% sodium nitrite with a purity of 99%, 1% fatty alcohol polyoxyethylene ether with a purity of 99%, 1.5% hydrochloric acid with a purity of 35%, 5% citric acid with a purity of 99%, 1% oxalic acid with 99% purity, 10% ethanol with 95% purity, 0.1% Cathone with 10% purity, 0.05% essence with 99% purity, and the balance is purified deionized water;

[0028] S102: dissolving sodium nitrite, fatty alcohol polyoxyethylene ether, hydrochloric acid, citric acid, oxalic acid, ethanol, kathone, and essence in purified deionized water, and stirring to obtain a homogeneous solution;

[0029] S103: adding purified deionized water to the full amount, constant volume and aging;

[0030] S104: inspecting the obtained intermediate product;

[0031] S105: If qualified, use plas...

Embodiment

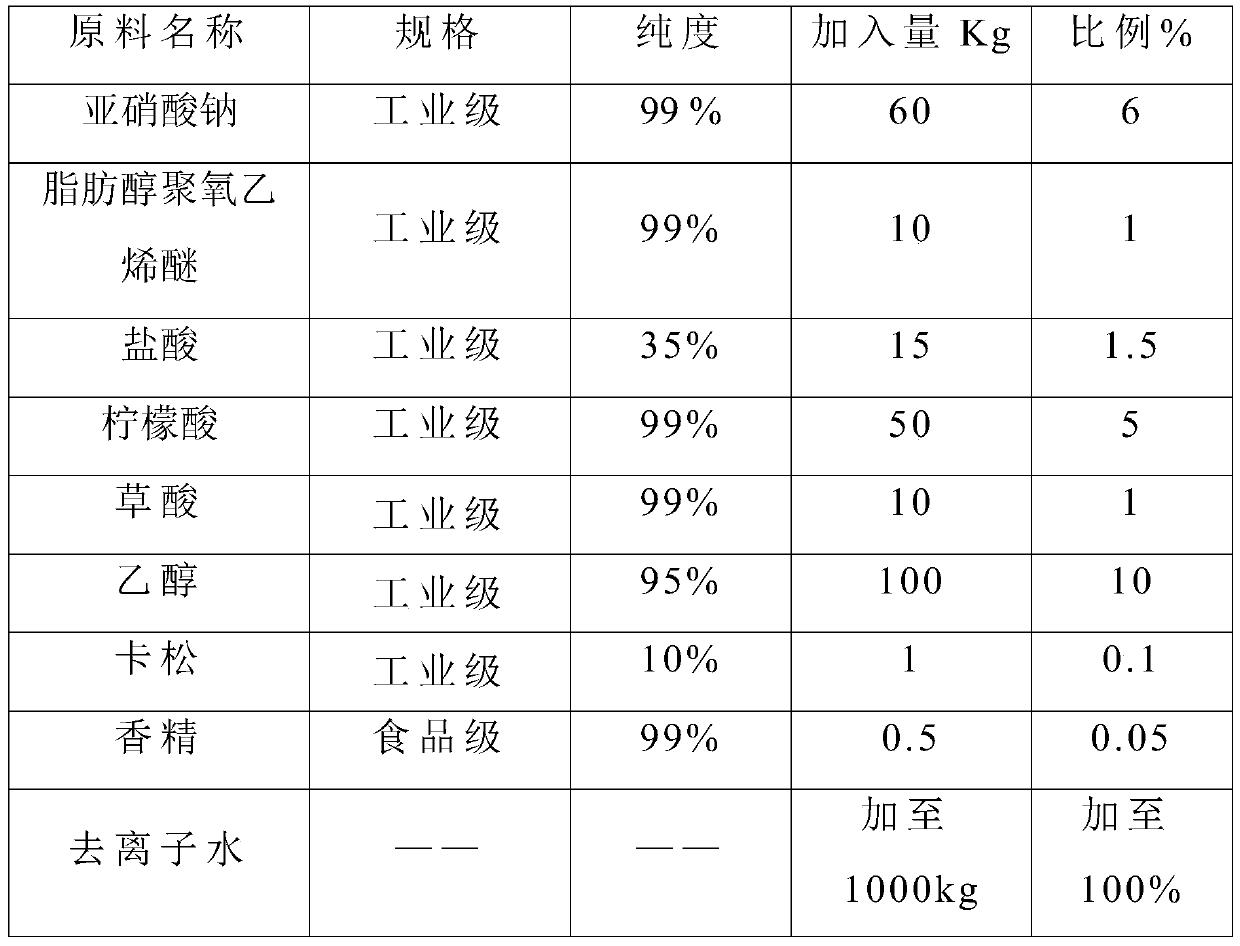

[0035] 1000kg product prescription composition:

[0036]

[0037] The following rust remover prepared by using the present invention is compared with the rust remover on the market as follows, and the rust remover on the surface of the same medical device, the specific data are shown in the table below;

[0038]

[0039]

[0040] It can be seen from the above comparative data that the present invention has the advantages of less rust removal under the same conditions, longer storage time after rust removal, no corrosion by acid and alkali after rust removal, and lower total volatile organic compounds than the rust removers on the market.

[0041] The rust remover of the present invention has moderate acidity, simple and safe operation, non-toxic and pollution-free, less rust removal process, can complete rust removal and decontamination at the same time, moderate rust removal rate, less usage, long storage time after rust removal, and Treated with acid and alkali, the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap