Multi-layer type vacuum radio frequency and hot wind combined drying method and equipment for rhizomatous traditional Chinese medicinal materials

A combined drying and hot air drying technology, used in lighting and heating equipment, heating to dry solid materials, and no heating to dry solid materials, etc., can solve the problems of slow drying, uneven material, and small RF drying load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

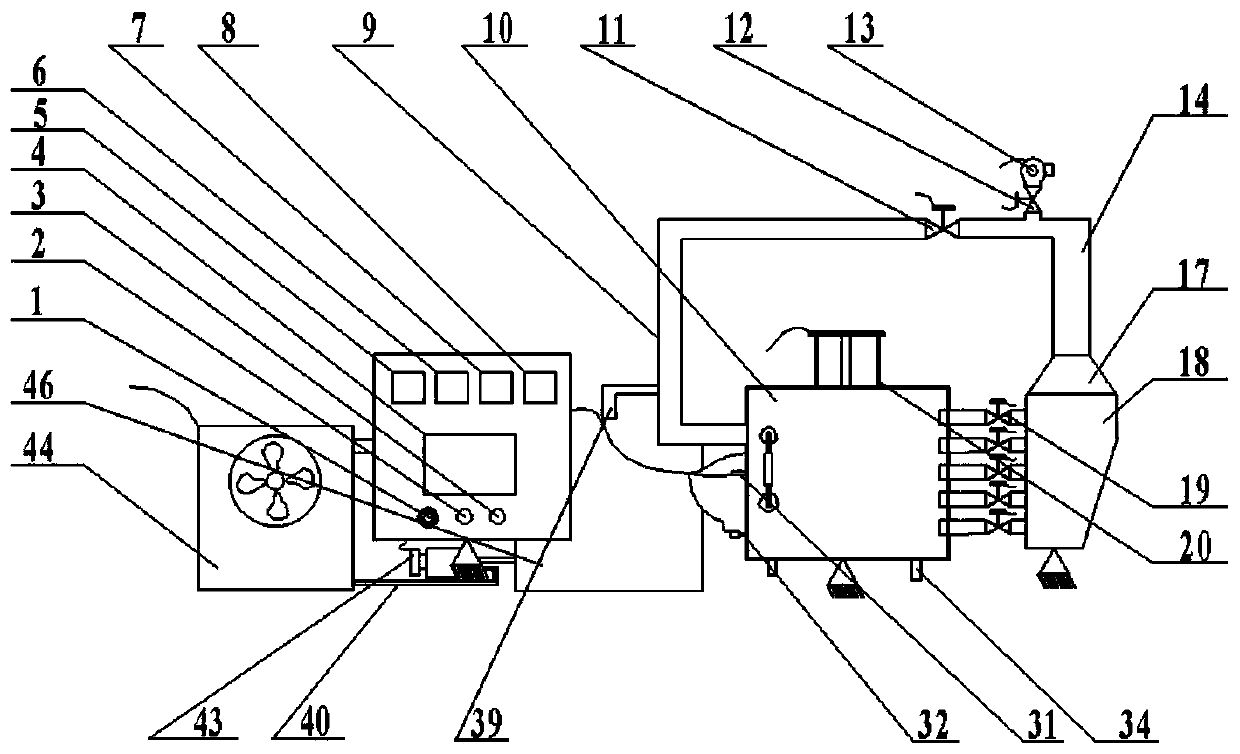

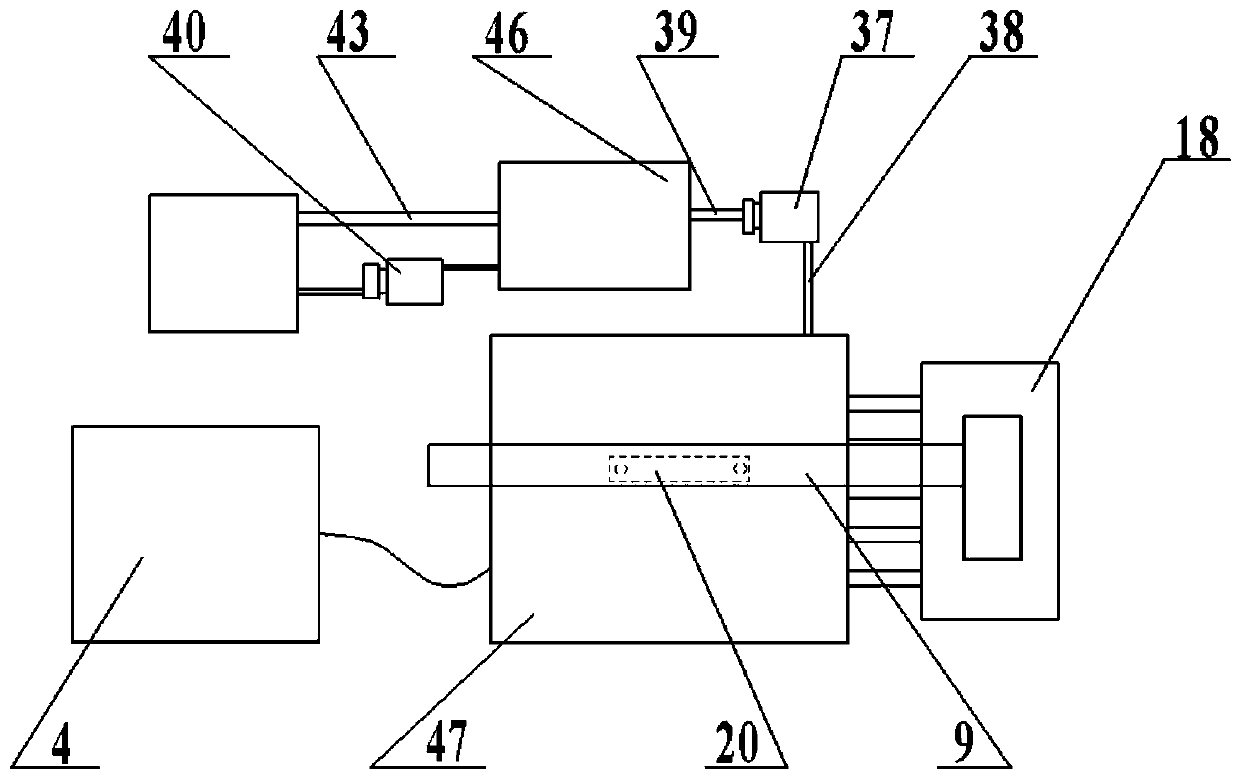

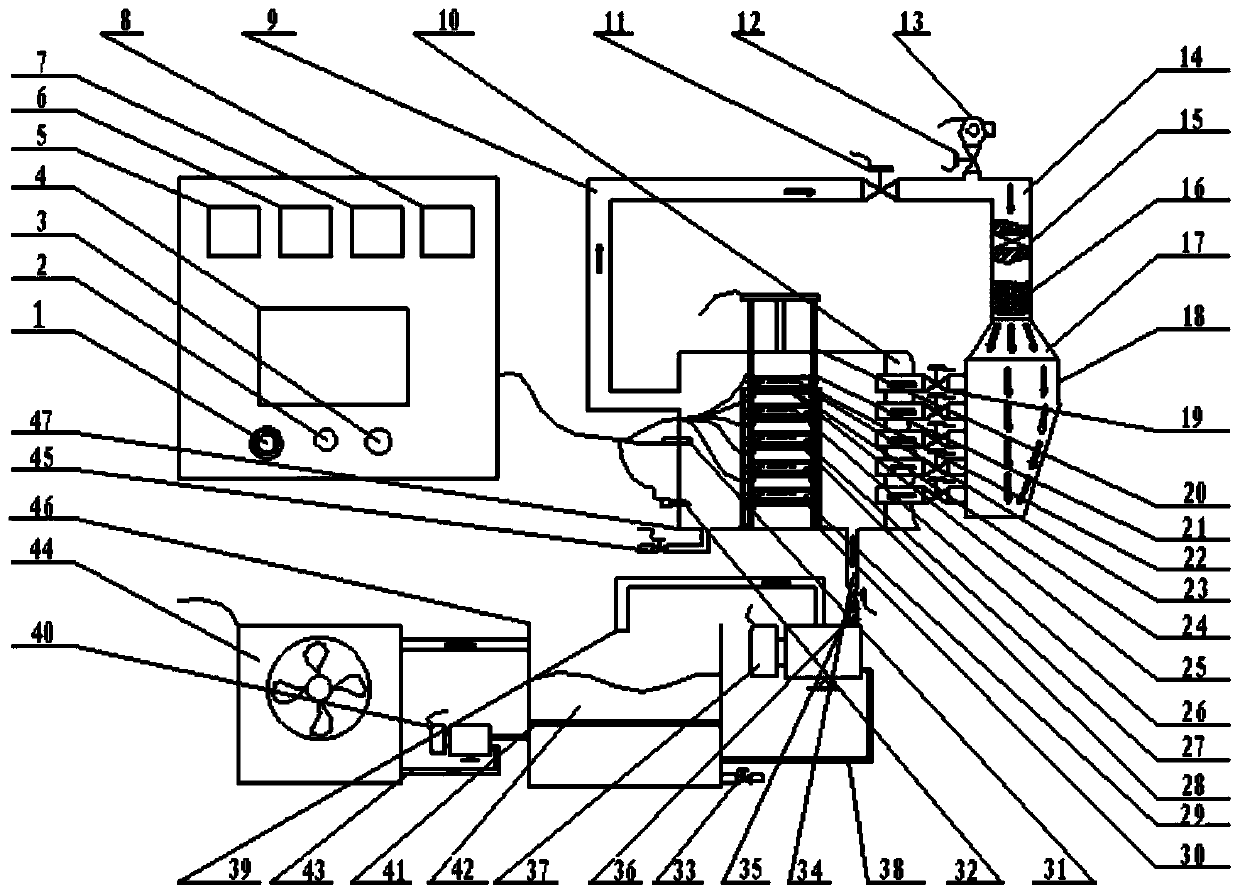

[0086] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0087] A multi-layer vacuum radio frequency-hot air combined drying equipment for rhizome Chinese medicinal materials, including: a circulating hot air drying system, a radio frequency heating system, a pulsating vacuum generating system and an automatic control system;

[0088] like Figure 1 ~ Figure 3 , Figure 7 As shown, the circulating hot air drying system includes a return air pipeline 9, a return air pipeline solenoid valve 11, a moisture discharge solenoid valve 12, a centrifugal fan 13, an air inlet pipeline 14, an axial flow fan 15, a heating pipe 16, and a pressure stabilizing chamber 17. The air distribution chamber 18 and the air inlet pipeline solenoid valve 19; wherein,

[0089] The air inlet side of the air return pipeline 9 communicates with the inside of the drying box 47 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com