Zn-Cu-Se composite material as well as preparation method and application thereof

A zn-cu-se, composite material technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, binary selenium/tellurium compounds, etc., which can solve the problems of low synthesis efficiency and unsatisfactory electrochemical performance. , to achieve high energy density and power density, improve electrochemical performance, and promote the effect of flow diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

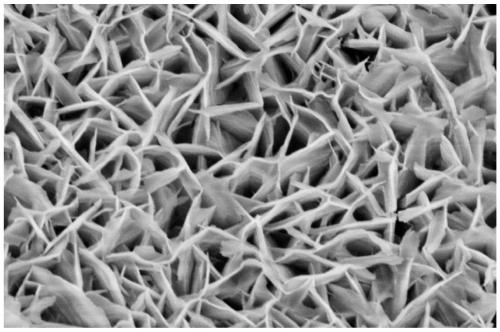

[0032] A preparation method of Zn-Cu-Se composite material includes the following steps:

[0033] Add 1mmol Zn(NO 3 ) 2 ·6H 2 O, 1mmol Cu(CH 3 COO) 2 ·H 2 O, 6mmol NH 4 F, 5mmol urea was dissolved in 40mL water, after magnetic stirring, transferred to a 50mL polytetrafluoroethylene lined stainless steel autoclave for one-step hydrothermal reaction, the hydrothermal reaction temperature was 180℃, and the hydrothermal reaction time was 6h; The hydrothermal samples were taken out and cooled, then centrifuged, washed, and vacuum dried at 60°C for 12 hours to obtain the Zn-Cu precursor. The Zn-Cu precursor prepared above and 60 mg of sodium selenite were dissolved in water and dispersed by magnetic stirring, and then 2 mL of ammonia was added to form a uniform suspension, and then the second hydrothermal reaction was carried out. The hydrothermal reaction temperature was 140°C. After the hydrothermal reaction time is 8 hours, the Zn-Cu-Se composite material is obtained by centrifugati...

Embodiment 2

[0039] A preparation method of Zn-Cu-Se composite material includes the following steps:

[0040] Add 1mmol Zn(NO 3 ) 2 ·6H 2 O, 0.5mmol Cu(CH 3 COO) 2 ·H 2 O, 6mmol NH 4 F, 5mmol urea was dissolved in 40mL water, after magnetic stirring, transferred to a 50mL polytetrafluoroethylene lined stainless steel autoclave for one-step hydrothermal reaction, the hydrothermal reaction temperature was 180℃, and the hydrothermal reaction time was 6h; The hydrothermal samples were taken out and cooled, then centrifuged, washed, and vacuum dried at 60°C for 12 hours to obtain the Zn-Cu precursor. The Zn-Cu precursor prepared above and 60 mg of sodium selenite were dissolved in water and dispersed by magnetic stirring, and then 2 mL of ammonia was added to form a uniform suspension, and then the second hydrothermal reaction was carried out. The hydrothermal reaction temperature was 140°C. After the hydrothermal reaction time is 8 hours, the Zn-Cu-Se composite material is obtained by centrifuga...

Embodiment 3

[0043] A preparation method of Zn-Cu-Se composite material includes the following steps:

[0044] Add 1mmol Zn(NO 3 ) 2 ·6H 2 O, 2mmol Cu(CH 3 COO) 2 ·H 2 O, 6mmol NH 4 F, 5mmol urea was dissolved in 40mL water, after magnetic stirring, transferred to a 50mL polytetrafluoroethylene lined stainless steel autoclave for one-step hydrothermal reaction, the hydrothermal reaction temperature was 180℃, and the hydrothermal reaction time was 6h; The hydrothermal samples were taken out and cooled, then centrifuged, washed, and vacuum dried at 60°C for 12 hours to obtain the Zn-Cu precursor. The Zn-Cu precursor prepared above and 60 mg of sodium selenite were dissolved in water and dispersed by magnetic stirring, and then 2 mL of ammonia was added to form a uniform suspension, and then the second hydrothermal reaction was carried out. The hydrothermal reaction temperature was 140°C. After the hydrothermal reaction time is 8 hours, the Zn-Cu-Se composite material is obtained by centrifugati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com