SA-LIGBT device with longitudinally separated anode

An anode and device technology, applied in the field of power semiconductor devices, can solve the problems of transistor voltage rebound, uneven current distribution of transistors, affecting device reliability, etc., so as to reduce turn-off loss, increase anode short-circuit resistance, and improve on-voltage drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

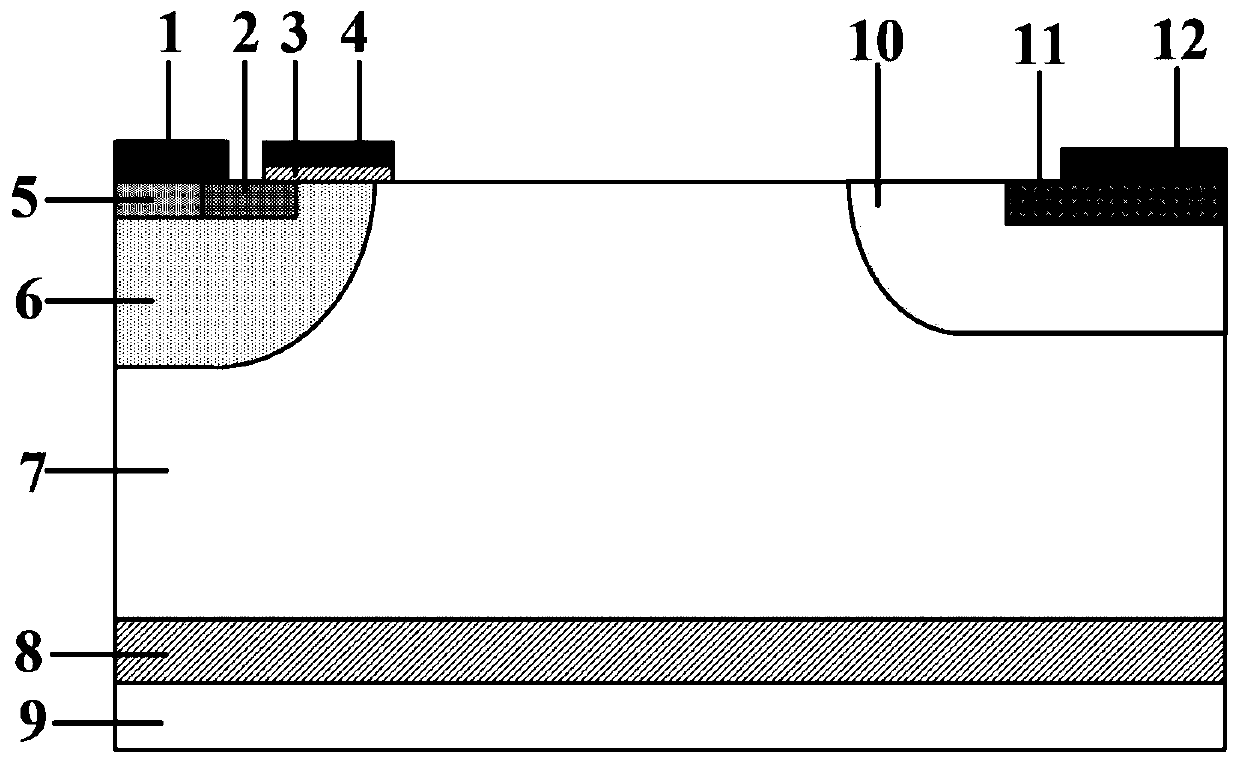

[0039] Such as Figure 5 As shown, a SA-LIGBT device with a vertically separated anode structure, its features include: cathode metal 1, N-type heavily doped cathode region 2, gate oxide layer 3, gate 4, P-type heavily doped cathode region 5 , P-body6, N-type drift region 7, insulating dielectric layer 8, P-type substrate 9, N-type buffer layer 10, P-type heavily doped anode region 11, anode metal 12, anode dielectric isolation layer 13, N-type heavy Doping the anode region 14 and the P-type floating layer 15 .

[0040] The P-type substrate 9, insulating dielectric layer 8 and N-type drift region 7 form an SOI structure. The P-type substrate is P-type doped silicon, and its thickness and doping concentration have a very wide selection range; the material of the insulating dielectric layer 8 is silicon dioxide with a thickness of 0.5 μm to 5 μm.

[0041] The N-type drift region 7 is covered on the insulating dielectric layer 8, and the N-type drift region 7 is silicon with a ...

Embodiment example 2

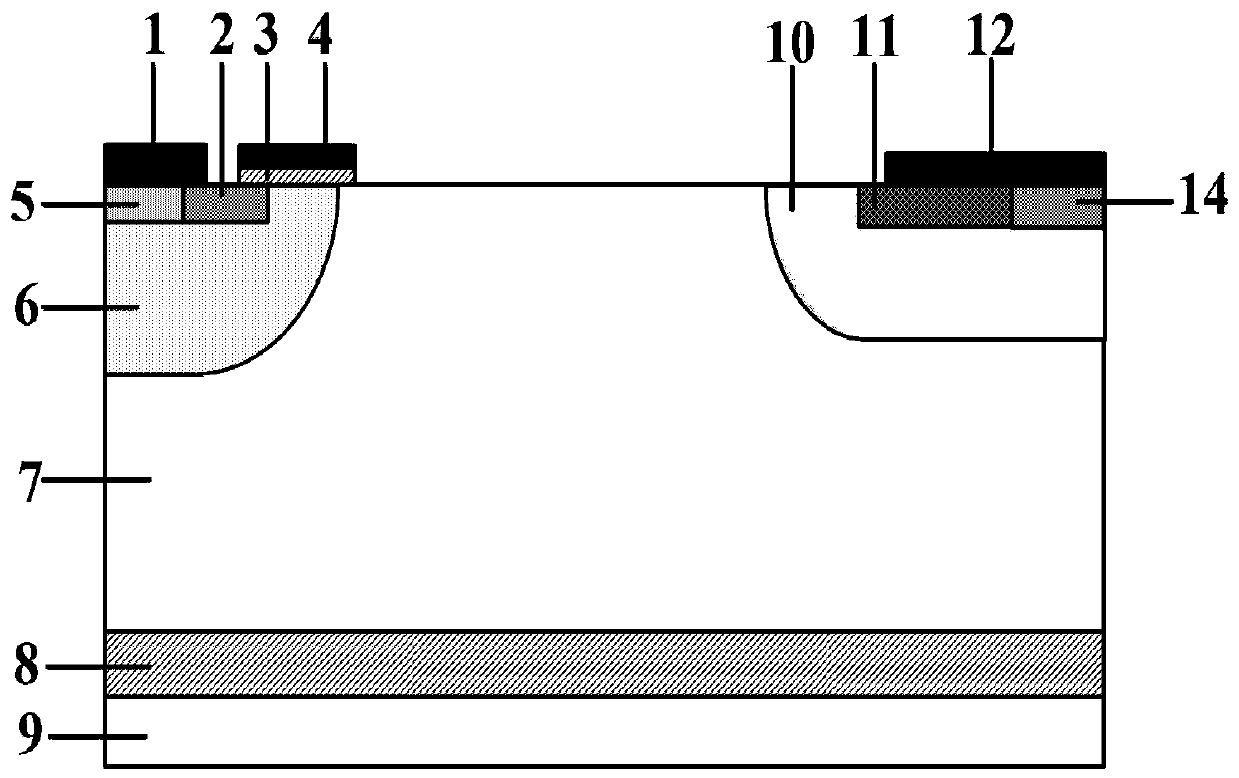

[0050] Such as Image 6 As shown, this example provides a SA-LIGBT device with a vertically separated anode structure. This implementation case is based on the implementation case 1, and the P-type floating layer 15 under the N-type heavily doped anode region 14 is removed. . The specific implementation plan is as follows:

[0051] A SA-LIGBT device with a vertically separated anode structure, which is characterized by: cathode metal 1, N-type heavily doped cathode region 2, gate oxide layer 3, gate 4, P-type heavily doped cathode region 5, P- body6, N-type drift region 7, insulating dielectric layer 8, P-type substrate 9, N-type buffer layer 10, P-type heavily doped anode region 11, anode metal 12, anode dielectric isolation layer 13, N-type heavily doped anode District 14.

[0052] The P-type substrate 9, insulating dielectric layer 8 and N-type drift region 7 form an SOI structure. The P-type substrate is P-type doped silicon, and its thickness and doping concentration ...

Embodiment example 3

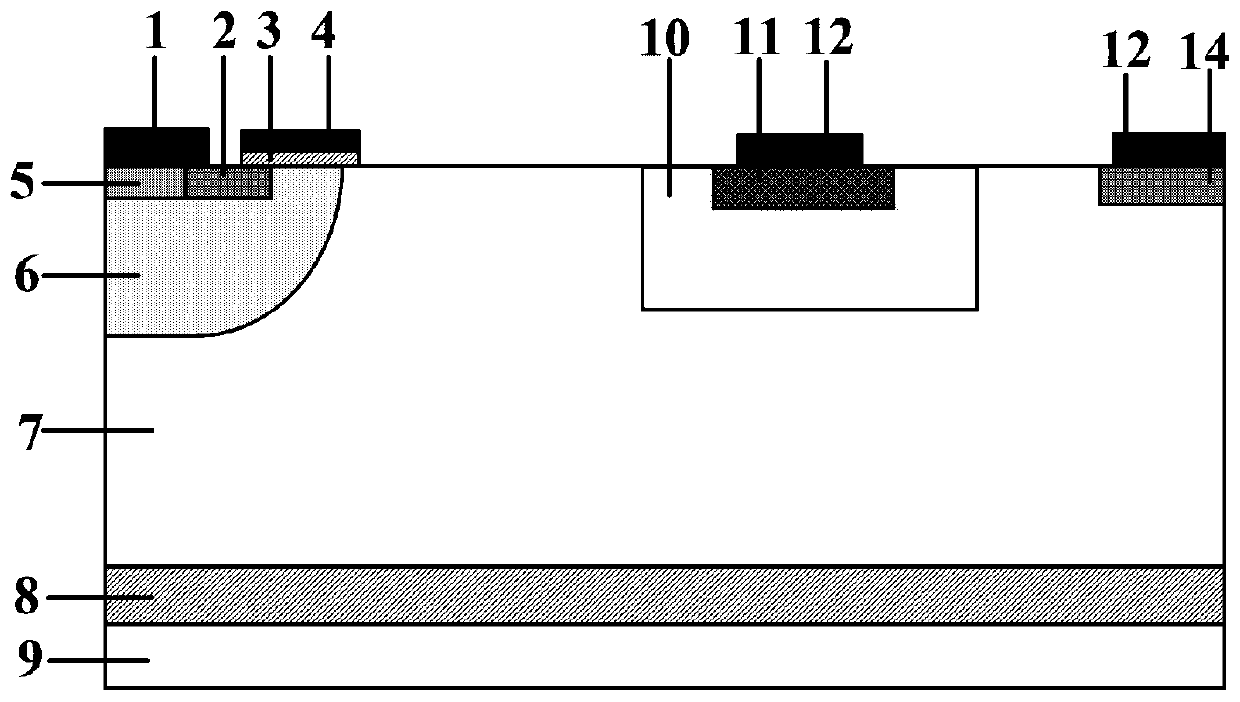

[0061] Such as Figure 7 As shown, this example provides a SA-LIGBT device with a vertically separated anode structure. On the basis of Embodiment 2, a P-type floating layer 15 is introduced directly below the anode dielectric isolation layer. The specific implementation plan is as follows:

[0062] Its features include: cathode metal 1, N-type heavily doped cathode region 2, gate oxide layer 3, gate 4, P-type heavily doped cathode region 5, P-body6, N-type drift region 7, insulating dielectric layer 8, P-type substrate 9 , N-type buffer layer 10 , P-type heavily doped anode region 11 , anode metal 12 , anode dielectric isolation layer 13 , N-type heavily doped anode region 14 , and P-type floating layer 15 .

[0063] The P-type substrate 9, insulating dielectric layer 8 and N-type drift region 7 form an SOI structure. The P-type substrate is P-type doped silicon, and its thickness and doping concentration have a very wide selection range; the material of the insulating diel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com