Novel emulsion with pH responsiveness

An emulsion and reaction technology, which is applied in organic chemistry, transportation and packaging, and the preparation of amino-substituted functional groups, etc., can solve the problems of difficult demulsification and low concentration of surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

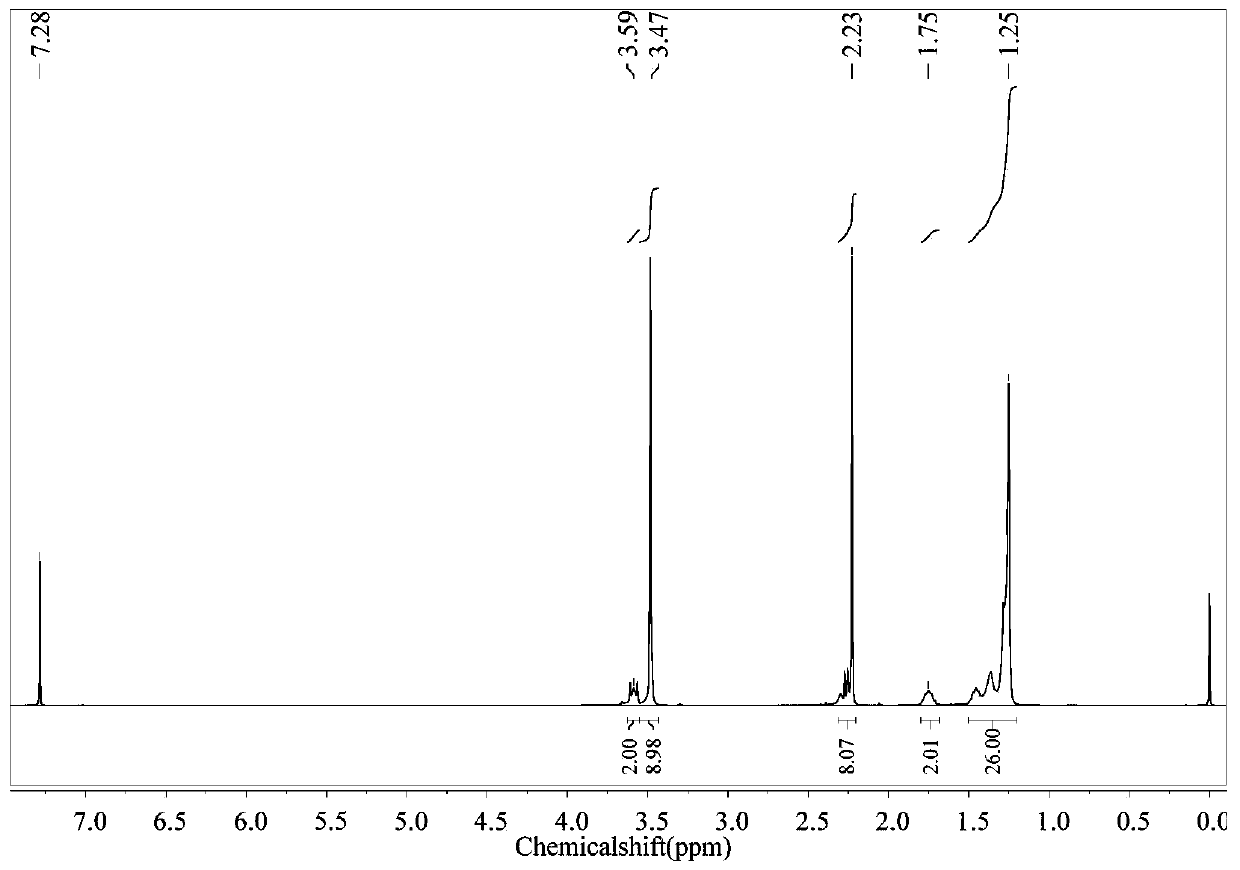

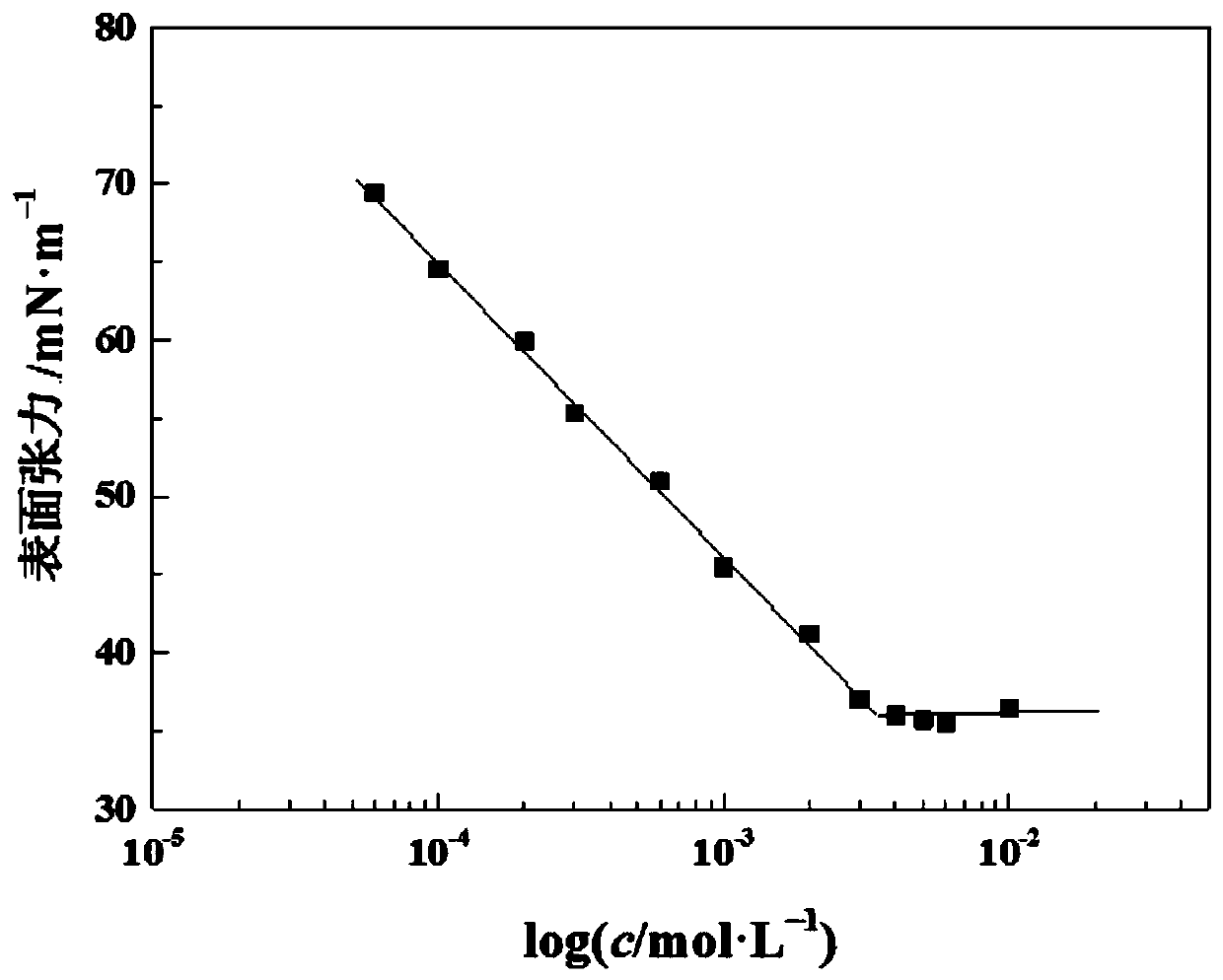

[0052] Embodiment 1: the preparation of tensio-active agent (N-C 16 -N + )

[0053]

[0054] (1) Acid chlorination reaction: Add hexadecanedioic acid solid (25g, 0.087mol) into a three-necked flask equipped with a device for absorbing tail gas and a reflux condenser, and add three drops of N,N-dimethylformamide as Catalyst, slowly dropwise add thionyl chloride (26g, 0.22mol). The reaction temperature was 60°C, and the reaction was carried out for 1 hour. Excess thionyl chloride was removed by rotary evaporation to obtain product 1.

[0055] (2) Amidation reaction: Place dimethylamine aqueous solution (154g, 1.37mol) in an ice-water bath, add dropwise a dichloromethane solution of product 1 (25g, 0.077mol), react for 2 hours after completion, and then use Dichloromethane was extracted 5 times, the combined extracts were washed with anhydrous Na 2 SO 4 The excess water was removed, the filtrate was obtained by suction filtration, the filtrate was rotary evaporated, and r...

Embodiment 2

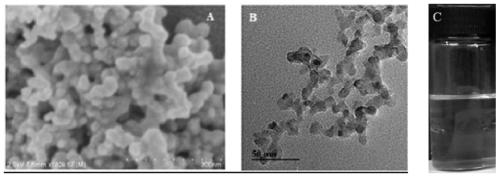

[0059] Embodiment 2: Nano Al 2 o 3 Surface Activity Detection of

[0060] Weigh 0.01g commercial nano-Al 2 o 3 Particles (primary particle size is about 13nm ( image 3 The shown SEM and TEM)) were placed in a 200mL bottle, 100g of ultrapure water was added, and dispersed in water with an ultrasonic disperser. The concentration of the particles is 0.01% by mass fraction (relative to the water phase). Pipette 7g of the particle solution into a 25mL bottle, add 7mL of n-decane, and emulsify with a high-shear homogenizer at a speed of 11000r / s for 2min, but no stable emulsion, indicating that the commercial nano-Al 2 o 3 Not surface active.

Embodiment 3

[0061] Embodiment 3: the preparation of novel emulsion

[0062] Weigh 0.0007g of nano-Al 2 o 3 Particles were ultrasonically dispersed in 7g of N-C with different concentrations 16 -N + (from left to right, 0.003mM, 0.006mM, 0.01mM, 0.03mM, 0.06mM, 0.1mM) solution, add 7mL of n-decane, emulsify with a high shear homogenizer for 2min, get Stable novel emulsions, such as Figure 4 As shown, this emulsion is still a stable emulsion after being placed for one month, and the appearance has no obvious change, indicating that the new emulsion obtained has better stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com