Novel emulsion with multiple response performance

An emulsion and responsive technology, applied in the preparation of organic compounds, organic chemistry, carboxylic acid amide preparation, etc., can solve problems such as difficulty in demulsification, and achieve the effect of reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

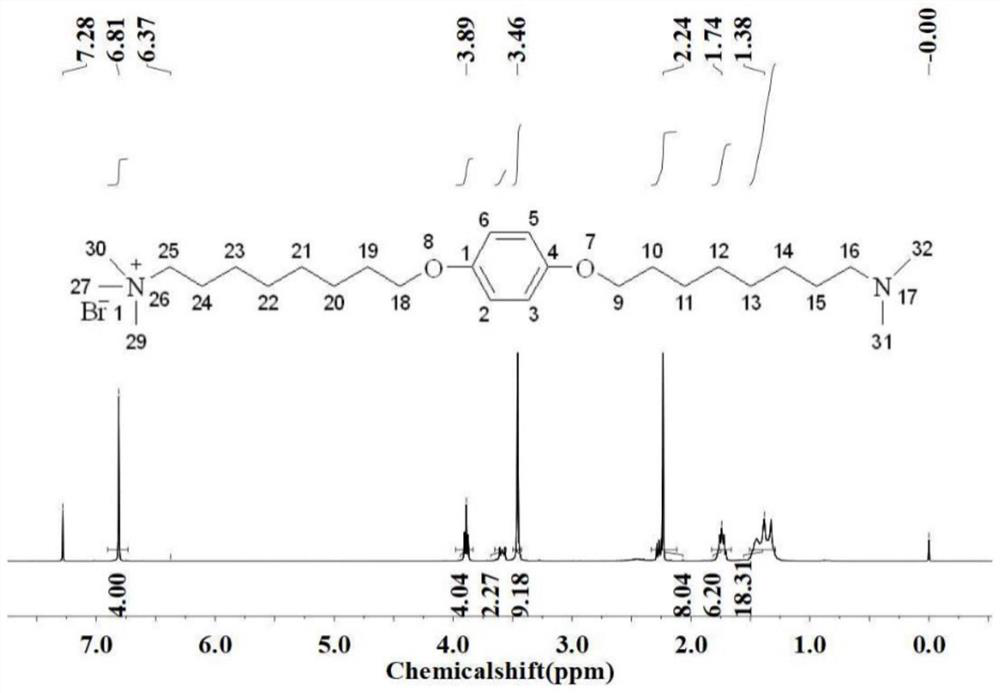

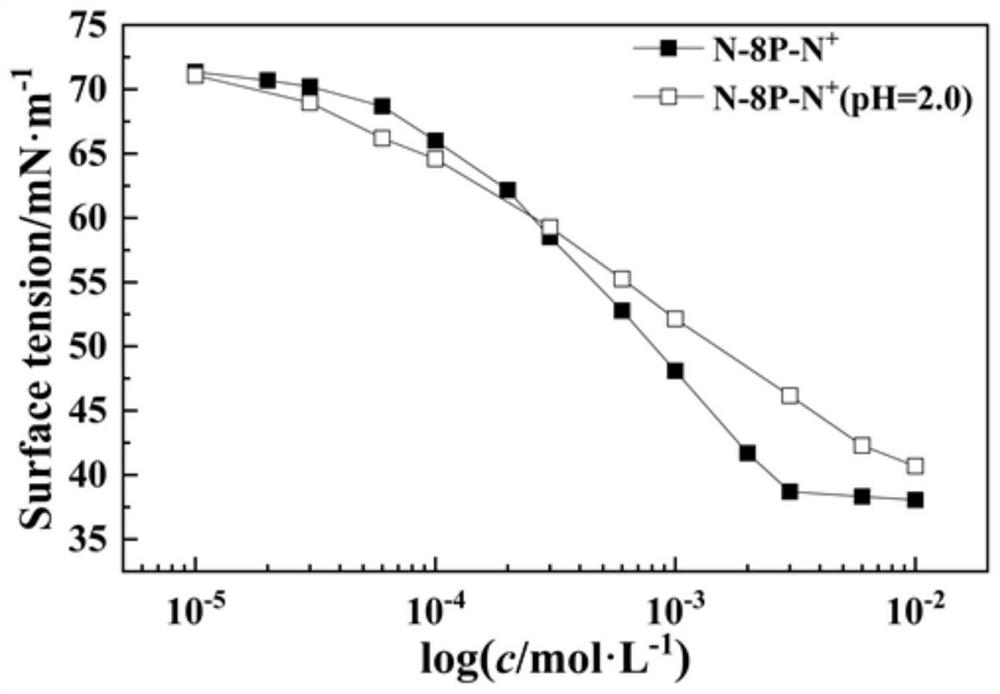

[0058] Embodiment 1: Surfactant N-8P-N + preparation of

[0059] Surfactant N-8P-N + The synthetic route of is as follows:

[0060]

[0061] (1) Acyl chloride reaction: Add 8-bromooctanoic acid solid (30g, 0.135mol) into a three-necked flask equipped with a device for absorbing tail gas and a reflux condenser, and add three drops of N,N-dimethylformamide as a catalyst , slowly added thionyl chloride (21 g, 0.178 mol) dropwise. The reaction temperature was 60° C., and the reaction was carried out for 1 h. Excess thionyl chloride was removed using a rotary evaporator to obtain Intermediate I.

[0062] (2) Amidation reaction: put dimethylamine hydrochloride (14g, 0.172mol) and triethylamine (50g, 0.494mol) in a low-temperature reactor at -10°C, and add intermediate Ⅰ (32.61g, 0.135mol) dropwise ) in dichloromethane solution, react for 2 hours after the end, and then extract the reaction solution with water for more than three times to remove excess triethylamine and dimeth...

Embodiment 2

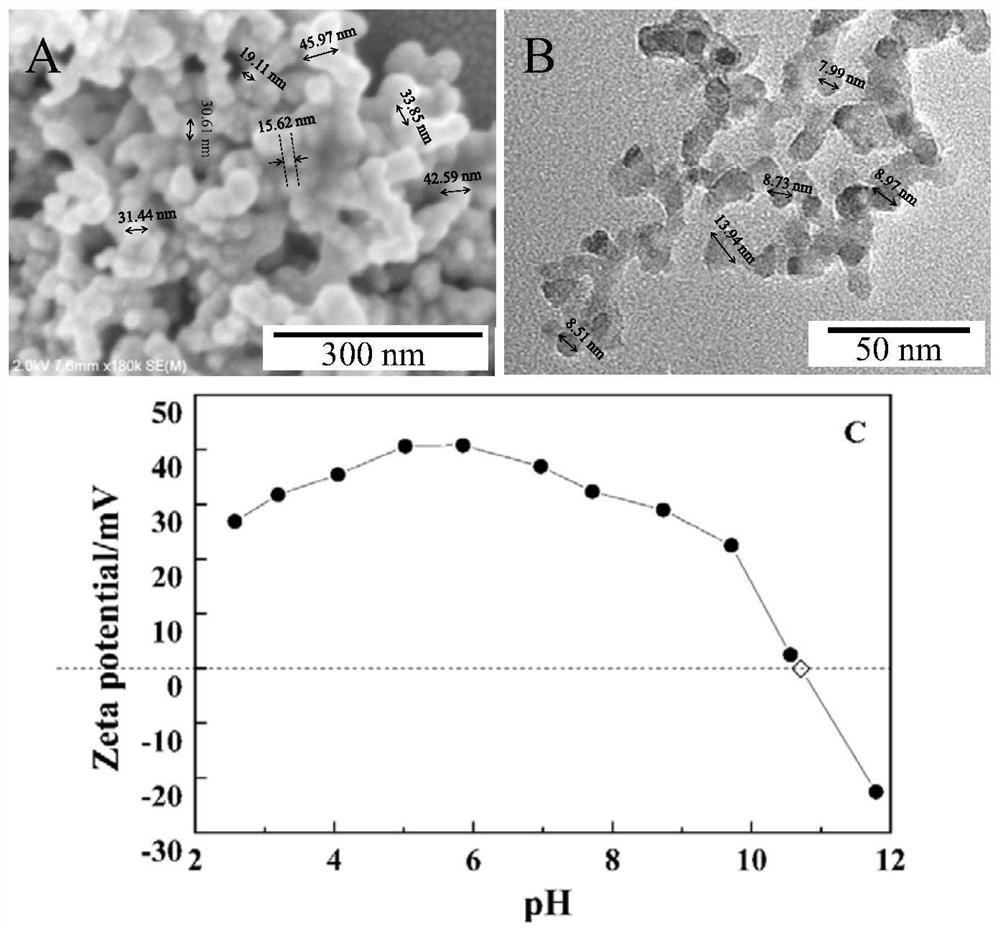

[0068] Embodiment 2: Nano Al 2 o 3 Surface Activity Detection of

[0069] Weigh 0.0007g commercial nano-Al 2 o 3 Particles (primary particle size is about 13nm, SEM and TEM such as image 3 As shown) in a 25mL glass bottle, add 7ml of ultrapure water, and disperse evenly with an ultrasonic disperser, and the mass fraction of the particles is 0.01% (relative to the water phase). Then add 7mL of n-decane and emulsify for 2min with a high-shear homogenizer at a speed of 11000r / s, but a stable emulsion cannot be obtained, indicating that the commercial nano-Al 2 o 3 Particles are not surface active, such as Figure 4 shown.

Embodiment 3

[0070] Embodiment 3: the preparation of novel emulsion

[0071] Weigh 0.0007g of nano-Al 2 o3 Ultrasonic dispersion of particles in 7mL of N-8P-N with different concentrations + In the solution, add 7mL of n-decane, and emulsify with a high-shear homogenizer for 2min to obtain a stable new emulsion, such as Figure 5 shown. The SEM picture of the emulsion is as follows Figure 6 shown. After shelving for one month, the emulsion has no obvious change in appearance and remains stable, indicating that the resulting novel emulsion has better stability. N-9P-N at the same concentration + , N-10P-N + have a similar stabilizing effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com