Microneedle patch containing insulin-loaded phenylboronic acid-based epsilon-polylysine and preparation method of microneedle patch

A technology of polylysine and insulin, which is applied to medical preparations containing active ingredients, medical preparations with non-active ingredients, and pharmaceutical formulas, etc. It can solve the problems of non-degradable particles, high preparation costs, and unfavorable disease control. Achieve the effect of low production cost, mild loading process and pain-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: microneedle patch

[0055] Mix 0.1010g of pullulan, 1.0172g of water and 0.0250g of insulin-loaded phenylboronic acid-based ε-polylysine particles to obtain the precursor of the microneedle patch. Add the precursor to the female microneedle mold, centrifuge at 3500rpm for 40min at a temperature of 25°C, inject the precursor into the needle groove of the female microneedle mold, and dry the precursor. The drying temperature is 30°C, the pressure is 0.1MPa, and the drying time is 24h. The microneedle patch obtained after drying is taken out to obtain a microneedle patch containing insulin-loaded phenylboronic acid-based ε-polylysine.

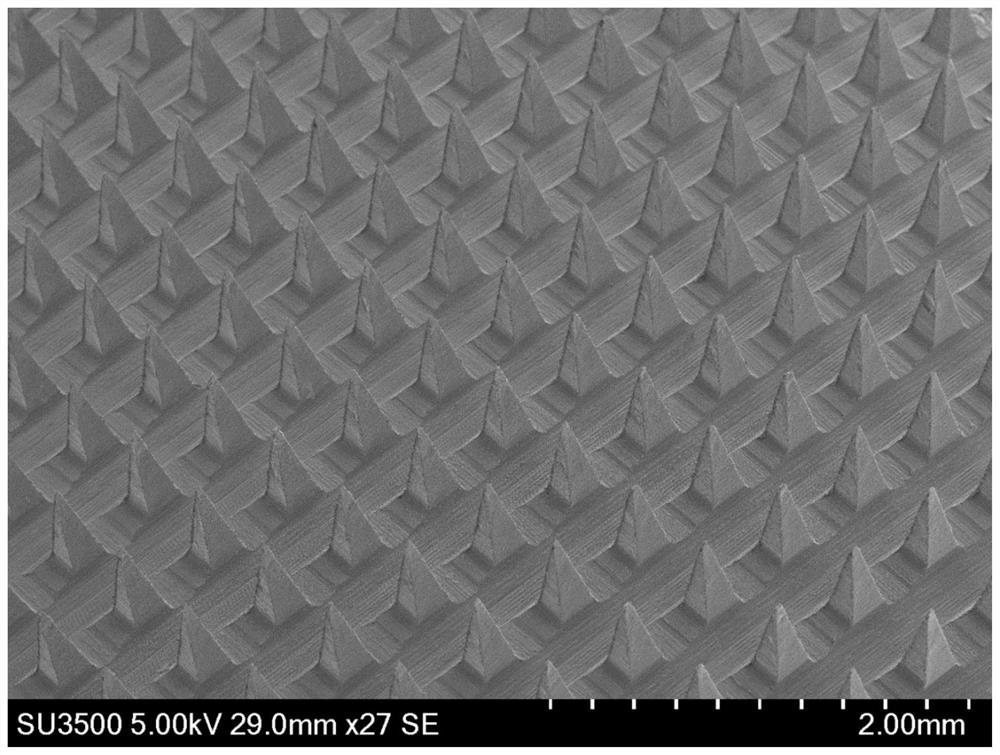

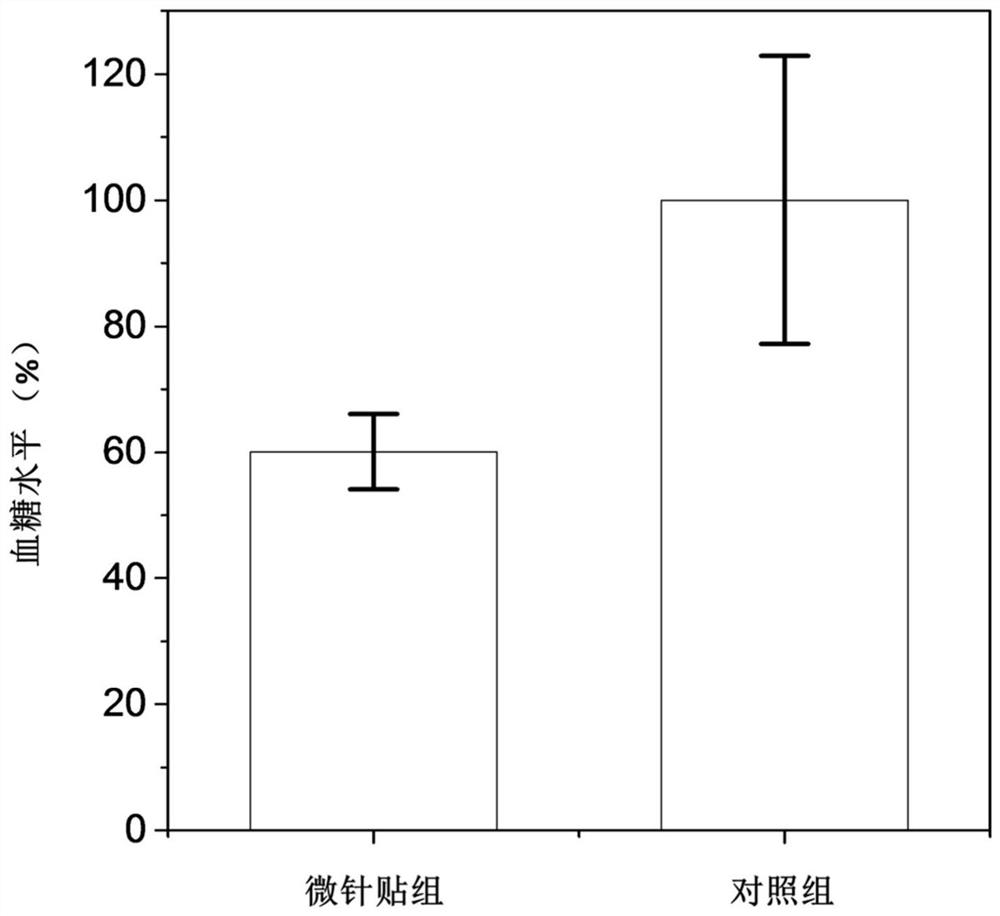

[0056] The results of this implementation case are as follows Figure 1-Figure 2 shown. figure 1 This is the electron micrograph of the microneedle patch containing insulin-loaded phenylboronic acid-based ε-polylysine. The microneedle patch was obtained through a simple centrifugation process, and the microneedle has a uniform...

Embodiment 2

[0058] Embodiment 2: microneedle patch

[0059] Mix 0.0562g of sodium hyaluronate, 1.0005g of water and 0.0251g of insulin-loaded phenylboronic acid-based ε-polylysine particles to obtain the precursor of the microneedle patch. Add the precursor to the female microneedle mold, centrifuge at 4000rpm for 100min at a temperature of 30°C, inject the precursor into the needle groove of the female microneedle mold, and dry the precursor. The drying temperature is 25°C, the pressure is 0.1MPa, and the drying time is 48h. The microneedle patch obtained after drying is taken out to obtain a microneedle patch containing insulin-loaded phenylboronic acid-based ε-polylysine.

Embodiment 3

[0060] Embodiment 3: microneedle patch

[0061] Mix 0.1002g of polyvinylpyrrolidone and 1.0005g of water with 0.0262g of insulin-loaded phenylboronic acid-based ε-polylysine particles to obtain the precursor of the microneedle patch. Add the precursor to the female microneedle mold, place it in a negative pressure environment, the pressure is 0.001MPa, the time is 0.5h, the temperature is 25°C, inject the precursor into the needle groove of the microneedle female mold, and dry the precursor. The drying temperature is 25°C, the pressure is 0.1MPa, and the drying time is 48h. The microneedle patch obtained after drying is taken out to obtain a microneedle patch containing insulin-loaded phenylboronic acid-based ε-polylysine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com