A kind of multifunctional protective material and its production method and application

A protective material and multi-functional technology, applied in the fields of application, protective clothing, chemical instruments and methods, etc., to achieve good air permeability and improve the effect of microenvironment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

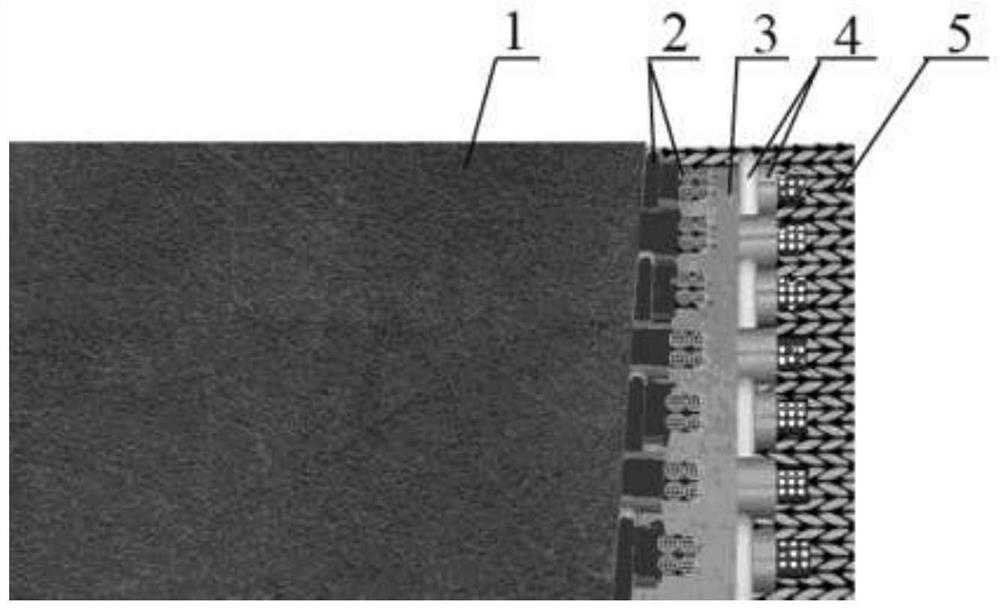

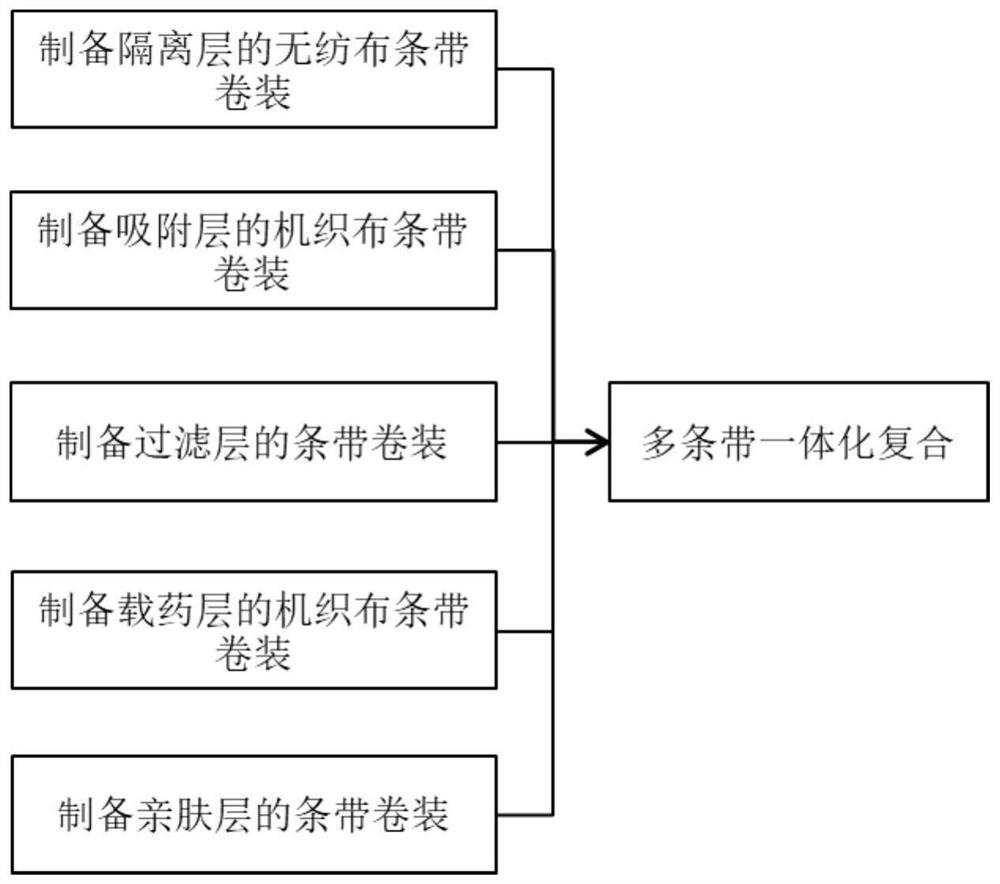

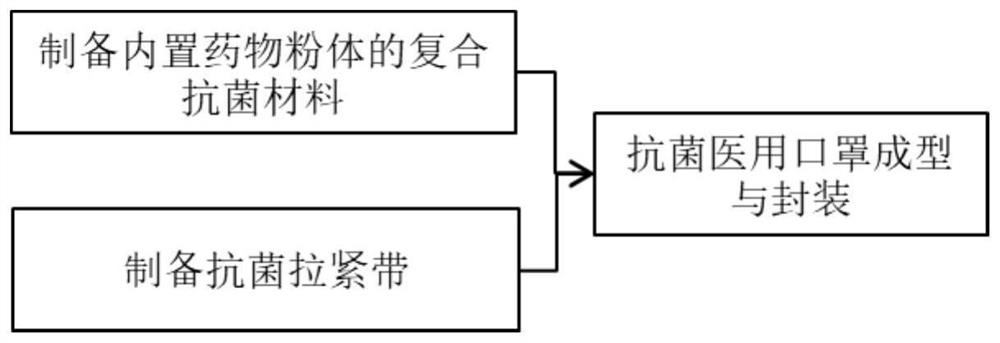

[0063] A multifunctional protective material, the preparation method is as follows:

[0064] (1) Prepare the non-woven strip package of isolation layer 1

[0065] Select surface density as 50g / m 2 The hemp medical antibacterial non-woven fabric is cut into 20cm wide non-woven fabric strips by FQJ automatic deviation-correcting strip slitting machine, and then wound on a cylindrical paper tube in parallel at a line speed of 125m / min to obtain an isolation layer 1 non-woven tape roll;

[0066] (2) Prepare the woven cloth strip package of adsorption layer 2

[0067] A PP non-woven fabric strip with a width of 10mm is used to wrap the carbon microspheres containing nanopores into a yarn. The mass fraction of the built-in carbon microspheres in the yarn body is 55%, and the fineness is 40tex. It is used as a weft yarn, and 21tex polyester is used. The sewing thread is used as the warp yarn, and the woven fabric with built-in carbon microspheres is made on the rapier loom. The wo...

Embodiment 2

[0077] A kind of multi-functional protection material, compared with embodiment 1, difference is that, in the process of the woven cloth strip package that prepares adsorption layer 2 in step (2), adopt built-in carbon microsphere mass fraction to be 55% 1. The PP non-woven strip covering yarn with a fineness of 200tex is used as the weft yarn, and the 21tex polyester sewing thread is used as the warp yarn, and the woven surface with built-in carbon microspheres is made on a rapier loom;

[0078] When step (4) prepares the strip package of drug-loaded layer 4, adopt the PP non-woven fabric strip that width is 12mm to wrap up ribavirin drug explosive bead into yarn, the ribavirin of yarn body The mass fraction of drug explosive beads is 30%, and the yarn fineness is 40tex, which is used as weft yarn, and 21tex polyester sewing thread is used as warp yarn, and a woven fabric with built-in interferon drug explosive beads is made on a rapier loom.

[0079] The rest of the steps ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com