Porous graphene and preparation method in magnetic field environment

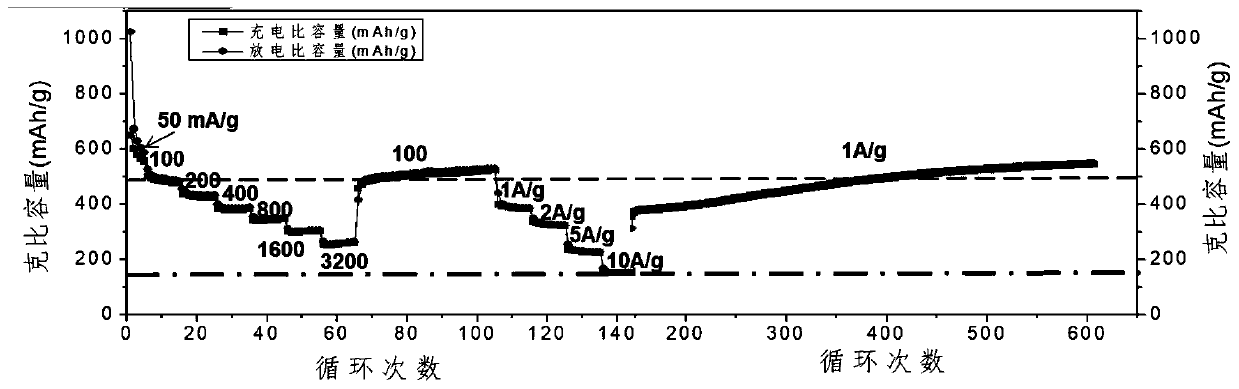

A porous graphene, graphene technology, applied in graphene, chemical instruments and methods, control/adjustment processes, etc., can solve the problems of small pore size range of porous graphene, uncontrollable preparation process, many defects in finished products, etc. The effect of large distribution range, suitable for large-scale industrial production and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

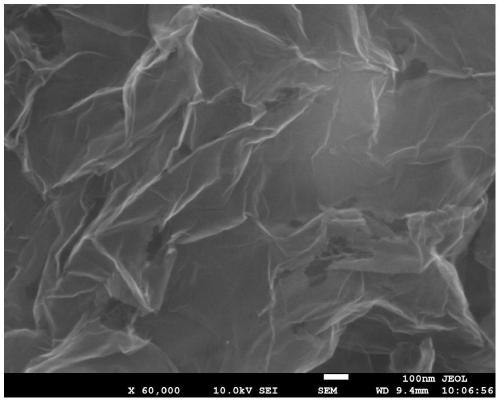

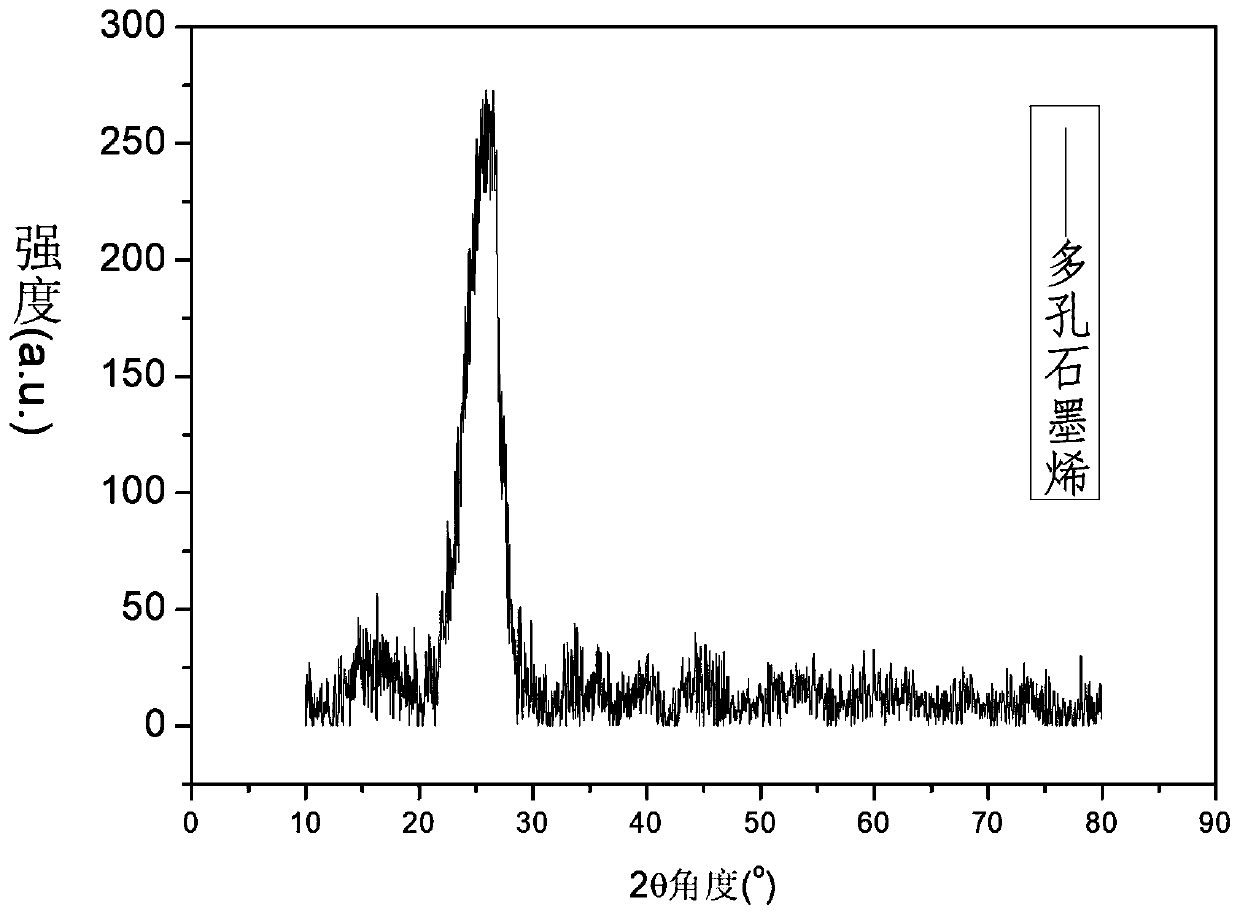

[0033] Embodiment 1: the preparation of porous graphene

[0034] 1) Take 10 mg of ferrocene and add it to 100 mL of ethanol, stir and dissolve to obtain a 0.1 mg / mL solution, continue to stir, take 10 mg / mL graphene oxide aqueous solution and add it to the above solution, ultrasonically disperse for 60 min at 100 W power, then transfer to In the reaction kettle, the height of the permanent magnet preset in the reaction kettle is equal to the liquid level of the solution added, and the volume of the permanent magnet accounts for 5% of the total volume. The temperature is raised to 90°C and kept at a constant temperature for 24h;

[0035] 2) Suction filter the reaction product in step 1, wash with ethanol until it is colorless, freeze-dry, place the freeze-dried product in a carbonization furnace, and heat-treat at 700° C. for 6 hours;

[0036] 3) Wash the product of step 2 in a dilute acid solution, stir for 24 hours, filter with suction, wash with water until neutral, and dry ...

Embodiment 2

[0037] Embodiment 2: the preparation of porous graphene

[0038] 1) Take 300 mg of nickelocene and add it to 100 mL of ethanol, stir and dissolve to obtain a 3 mg / mL solution, continue to stir, take 2.99 mg / mL graphene oxide aqueous solution into the above solution, ultrasonically disperse at 300 W for 32.5 min, transfer Into the reaction kettle, the height of the permanent magnet preset in the reaction kettle is equal to the liquid level of the solution added, the volume of the permanent magnet accounts for 20% of the total volume, the temperature is raised to 135°C, and the temperature is kept constant for 13h;

[0039] 2) Suction filter the reaction product in step 1, wash with ethanol until it is colorless, freeze-dry, place the freeze-dried product in a carbonization furnace, and heat-treat at 950°C for 3.25h;

[0040] 3) Wash the product of step 2 in a dilute acid solution, stir for 12.5 h, filter with suction, wash with water until neutral, and dry (90° C., 14 h) to obt...

Embodiment 3

[0041] Embodiment 3: the preparation of porous graphene

[0042] 1) Add 500mg of cobalt dicene into 100mL ethanol, stir and dissolve to obtain a 5mg / mL solution, continue to stir, take 2.5mg / mL graphene oxide aqueous solution and add it to the above solution, ultrasonically disperse for 5min at 500W power, then transfer to In the reaction kettle, the height of the permanent magnet preset in the reaction kettle is equal to the liquid level of the solution added, and the volume of the permanent magnet accounts for 50% of the total volume. The temperature is raised to 180°C and kept at a constant temperature for 2 hours;

[0043] 2) Suction filter the reaction product in step 1, wash with ethanol until it is colorless, freeze-dry, place the freeze-dried product in a carbonization furnace, and heat-treat at 1200°C for 0.5h;

[0044] 3) Wash the product of step 2 in a dilute acid solution, stir for 1 h, filter with suction, wash with water until neutral, and dry (120° C., 4 h) to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com