Antibacterial modal composite fabric and preparation method thereof

A technology of composite fabric and modal fiber, which is applied in the field of antibacterial modal composite fabric and its preparation, can solve the problems of unsatisfactory antibacterial rate and achieve excellent antibacterial performance, soft texture and high antibacterial rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

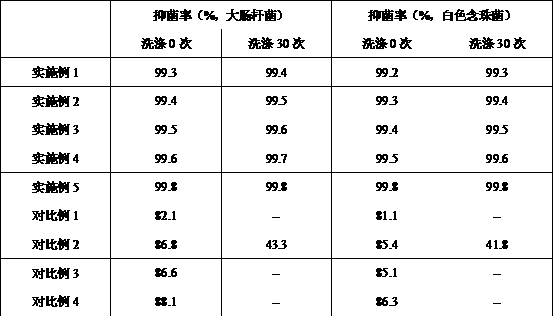

Examples

Embodiment 1

[0028] A preparation method of antibacterial modal composite fabric, first blending 10kg modal fiber and 3kg nano-modified polyester fiber into the first yarn, weaving on the machine to form an inner surface layer and an outer layer, then 7kg modal fiber, 5kg apocynum fiber, 1kg bamboo fiber and 0.2kg chitin fiber are blended into the second yarn, and the middle layer is formed by upper machine weaving to obtain the described a kind of antibacterial modal composite fabric; wherein, the nano-modified polyester fiber is obtained by combining polyester chips with The graphene-zinc oxide nanopowder modified by γ-aminopropyltriethoxysilane is obtained by melt spinning at a mass ratio of 1:0.03, and the graphene-zinc oxide nanopowder is obtained at a molar ratio of 1:5 It is made of graphene oxide and zinc nitrate as raw materials.

[0029]The preparation method of graphene-zinc oxide nanopowder is as follows: first dissolve zinc nitrate in 5 times the weight of deionized water, sti...

Embodiment 2

[0037] A preparation method of antibacterial modal composite fabric, first blending 10kg modal fiber and 4kg nano-modified polyester fiber into the first yarn, weaving on the machine to form an inner surface layer and an outer layer, then 8kg modal fiber, 6kg apocynum fiber, 2kg bamboo fiber and 0.4kg chitin fiber are blended into the second yarn, and the middle layer is formed by upper machine weaving to obtain the described a kind of antibacterial modal composite fabric; wherein, the nano-modified polyester fiber is obtained by combining polyester chips with The graphene-zinc oxide nanopowder modified by γ-aminopropyltriethoxysilane is obtained by melt spinning at a mass ratio of 1:0.05, and the graphene-zinc oxide nanopowder is obtained at a molar ratio of 1:8 It is made of graphene oxide and zinc nitrate as raw materials.

[0038] The preparation method of graphene-zinc oxide nanopowder is as follows: first dissolve zinc nitrate in 8 times the weight of deionized water, st...

Embodiment 3

[0046] A preparation method of antibacterial modal composite fabric, first blending 10kg modal fiber and 3kg nano-modified polyester fiber into the first yarn, weaving on the machine to form an inner surface layer and an outer layer, then 8kg modal fiber, 5kg apocynum fiber, 2kg bamboo fiber and 0.2kg chitin fiber are blended into the second yarn, and the upper weaving is used to form the middle layer to obtain the described a kind of antibacterial modal composite fabric; wherein, the nano-modified polyester fiber is obtained by combining polyester chips with The graphene-zinc oxide nanopowder modified by γ-aminopropyltriethoxysilane is obtained by melt spinning according to the mass ratio of 1:0.05, and the graphene-zinc oxide nanopowder is obtained by the molar ratio of 1:5 It is made of graphene oxide and zinc nitrate as raw materials.

[0047] The preparation method of graphene-zinc oxide nanopowder is as follows: first dissolve zinc nitrate in 8 times the weight of deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com