A damping tunnel segment

A technology of tunnel segment and cementitious material, applied in tunnels, tunnel lining, solid waste management, etc., can solve the problem of little research on vibration reduction of tunnel structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

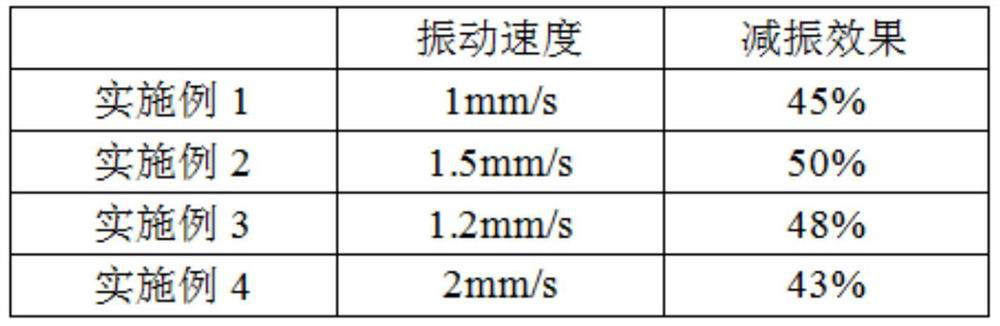

Embodiment 1

[0027] This embodiment provides a damping tunnel segment, the tunnel segment includes coarse aggregate, fine aggregate and cementitious material, the mass ratio of the coarse aggregate is 60%, and the fine aggregate ratio is 20% %, the cementitious material accounts for 20%; the coarse aggregate has a density of 3000kg / m 3 Iron ore slag, the fine aggregate is a density of 1700kg / m 3 water sand, the density of the cementitious material is 1000kg / m 3 .

[0028] The cementitious material includes the following materials in parts by weight: 1 part of oleic acid, 2 parts of FDN water reducer, 40 parts of stone powder, 4 parts of mica powder, 1 part of diatomaceous earth, 2 parts of composite honeycomb material, and 3 parts of iron powder , 3 parts of precipitated barium sulfate, 1 part of stearic acid.

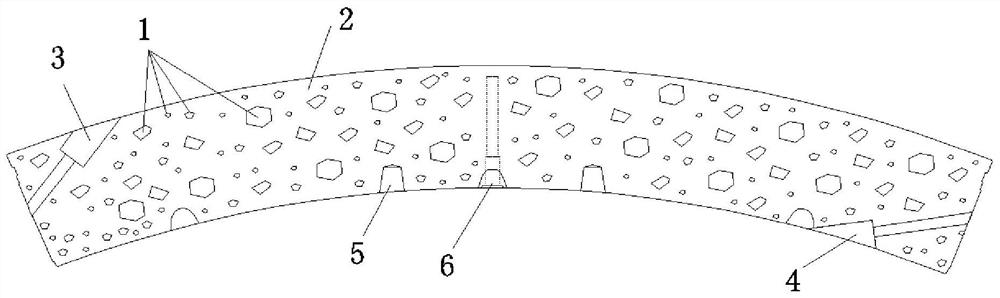

[0029] The two sides of the tunnel segment are respectively provided with a first connecting bolt hole 3 and a second connecting bolt hole 4, the first connecting bolt hole 3 an...

Embodiment 2

[0031] This embodiment provides a damping tunnel segment, the tunnel segment includes coarse aggregate, fine aggregate and cementitious material, the mass proportion of the coarse aggregate is 80%, and the proportion of fine aggregate is 10%, the proportion of cementitious material is 10%; the coarse aggregate has a density of 3500kg / m 3 Copper ore slag, the fine aggregate is 1600kg / m 3 machine-made sand, the density of the cementitious material is 300kg / m 3 .

[0032] The cementitious material includes the following materials in parts by weight: 2 parts of oleic acid, 1 part of FDN water reducer, 30 parts of copper ore slag, 2 parts of mica powder, 5 parts of diatomaceous earth, 8 parts of composite honeycomb material, iron powder 1 part, 1 part of precipitated barium sulfate, 0.2 part of stearic acid.

Embodiment 3

[0034] This embodiment provides a damping tunnel segment, the tunnel segment includes coarse aggregate, fine aggregate and cementitious material, the mass proportion of the coarse aggregate is 60%, and the proportion of fine aggregate is 10%, the proportion of cementitious material is 30%; the coarse aggregate has a density of 3800kg / m 3 Iron ore slag, the fine aggregate is a density of 1650kg / m 3 water sand, the density of the cementitious material is 1500kg / m 3 .

[0035] The cementitious material includes the following materials in parts by weight: 1.5 parts of oleic acid, 1.5 parts of FDN water reducer, 35 parts of stone powder, 3 parts of mica powder, 3 parts of diatomite, 5 parts of composite honeycomb material, and 2 parts of iron powder , 2 parts of precipitated barium sulfate, 0.6 parts of stearic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com