Intermetallic compound nano-catalyst as well as preparation method and application thereof

An intermetallic compound, nanocatalyst technology, applied in the field of electrochemistry, can solve the problem of no intermetallic compound and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing an intermetallic compound nano-catalyst, comprising: S1) mixing carbon black, iridium salt and gallium salt in a solvent, and obtaining the mixture after removing the solvent; S2) putting the mixture in a reducing atmosphere High temperature treatment is carried out to obtain the intermetallic compound nano catalyst.

[0032] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0033] Mix carbon black, iridium salt and gallium salt in a solvent; the carbon black can be commercial carbon black well known to those skilled in the art, without special restrictions, preferably commercial carbon black KJ600 and / or XC in the present invention -72R; the iridium salt is preferably iridium chloride; the gallium salt is preferably gallium nitrate; the mass ratio of the carbon black, iridium salt and gallium salt is preferably (35~45):(10~15):( 15~20), more preferab...

Embodiment 1

[0042] 40.00mg commercial carbon black KJ600, 11.38mg IrCl 3 With 16.38mg Ga(NO 3 ) 3 Disperse in 50 mL of water and stir evenly, and then perform rotary evaporation to remove solvent water to obtain a uniform mixture. The rotation speed during the rotary evaporation process is 90 rpm, the temperature of the water bath is 80° C., and the vacuum degree is 60 mbar.

[0043] The resulting homogeneous mixture was transferred to a quartz crucible, placed in a tube furnace, and then argon-hydrogen gas was introduced as a reducing gas (the volume ratio of argon and hydrogen was 95:5), and the tube furnace was heated at 5°C / min The temperature was raised to 800°C at a rate of 800°C, and kept for 8 hours; then the temperature was lowered to room temperature (20-30°C) at a rate of 5°C / min; the tube furnace was kept at normal pressure to obtain an intermetallic compound IrGa nano-catalyst.

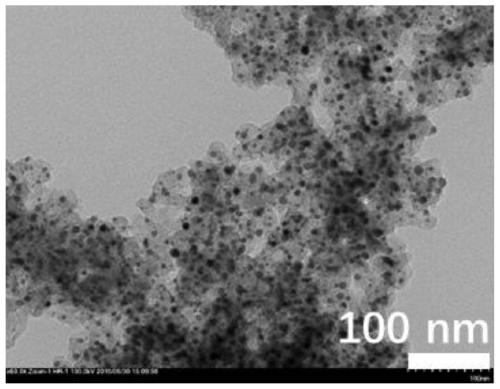

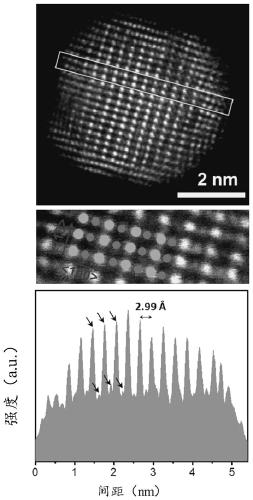

[0044] The intermetallic compound IrGa nano-catalyst prepared in Example 1 of the present inven...

Embodiment 2

[0054] 40.00mg commercial carbon black KJ600, 11.38mg IrCl 3 With 16.38mg Ga(NO 3 ) 3 Disperse in 50 mL of water and stir evenly, and then perform rotary evaporation to remove solvent water to obtain a uniform mixture. The rotation speed during the rotary evaporation process is 90 rpm, the temperature of the water bath is 80° C., and the vacuum degree is 60 mbar.

[0055] The resulting homogeneous mixture was transferred to a quartz crucible, placed in a tube furnace, and then argon-hydrogen gas was introduced as a reducing gas (the volume ratio of argon and hydrogen was 95:5), and the tube furnace was heated at 5°C / min The temperature was raised to 800 ° C at a rate of 2 h, and then the temperature was lowered to room temperature (20-30 ° C) at a rate of 5 ° C / min; the tube furnace was kept at normal pressure to obtain an intermetallic compound IrGa nano-catalyst.

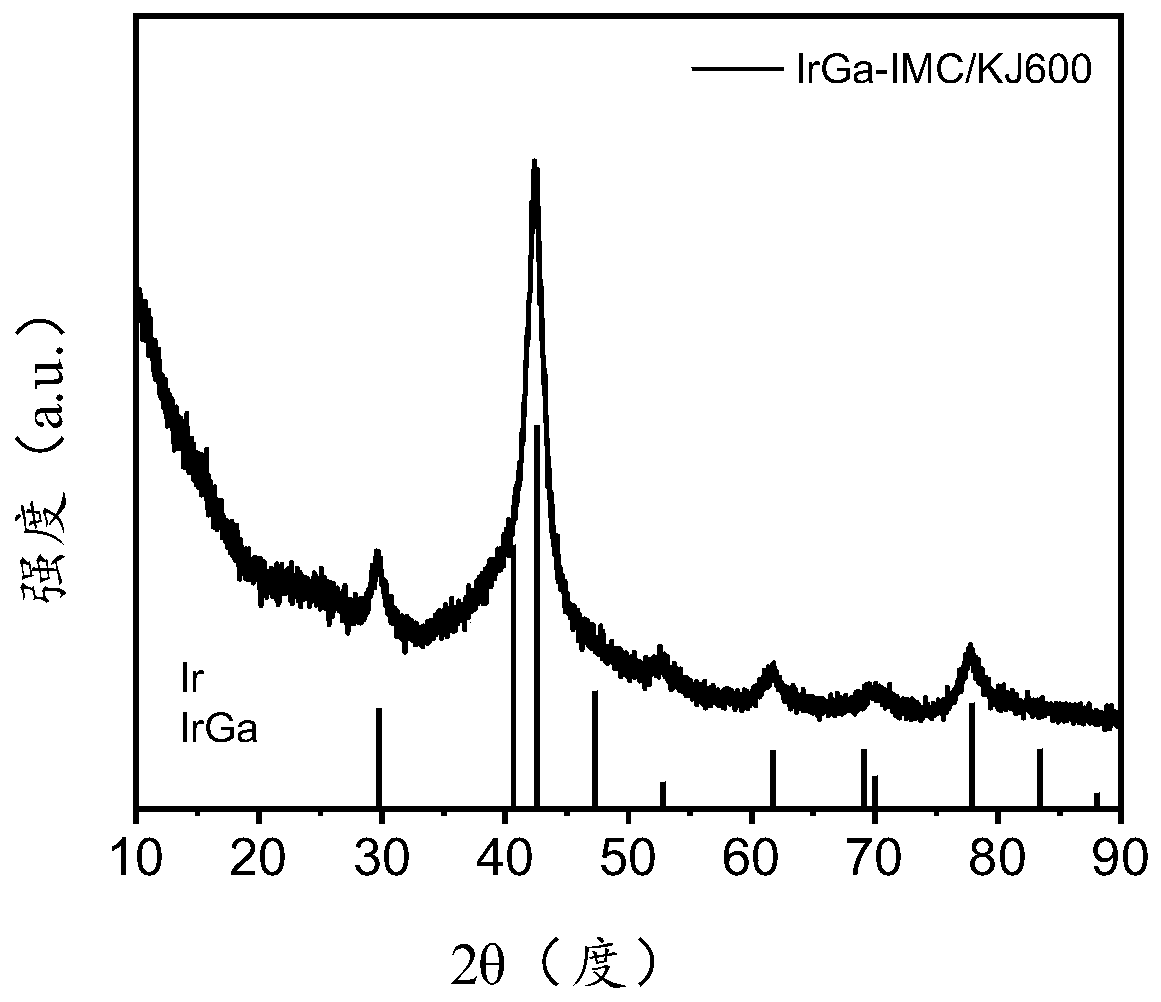

[0056] Carry out X-ray powder diffraction detection to the intermetallic compound IrGa nano-catalyst prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com