High-titanium slag sand reactive powder concrete and preparation method thereof

A high-titanium slag, active powder technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of ecological environment damage, low utilization rate of high-titanium slag, etc. The effect of shortage of raw materials and efficient and high-quality utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

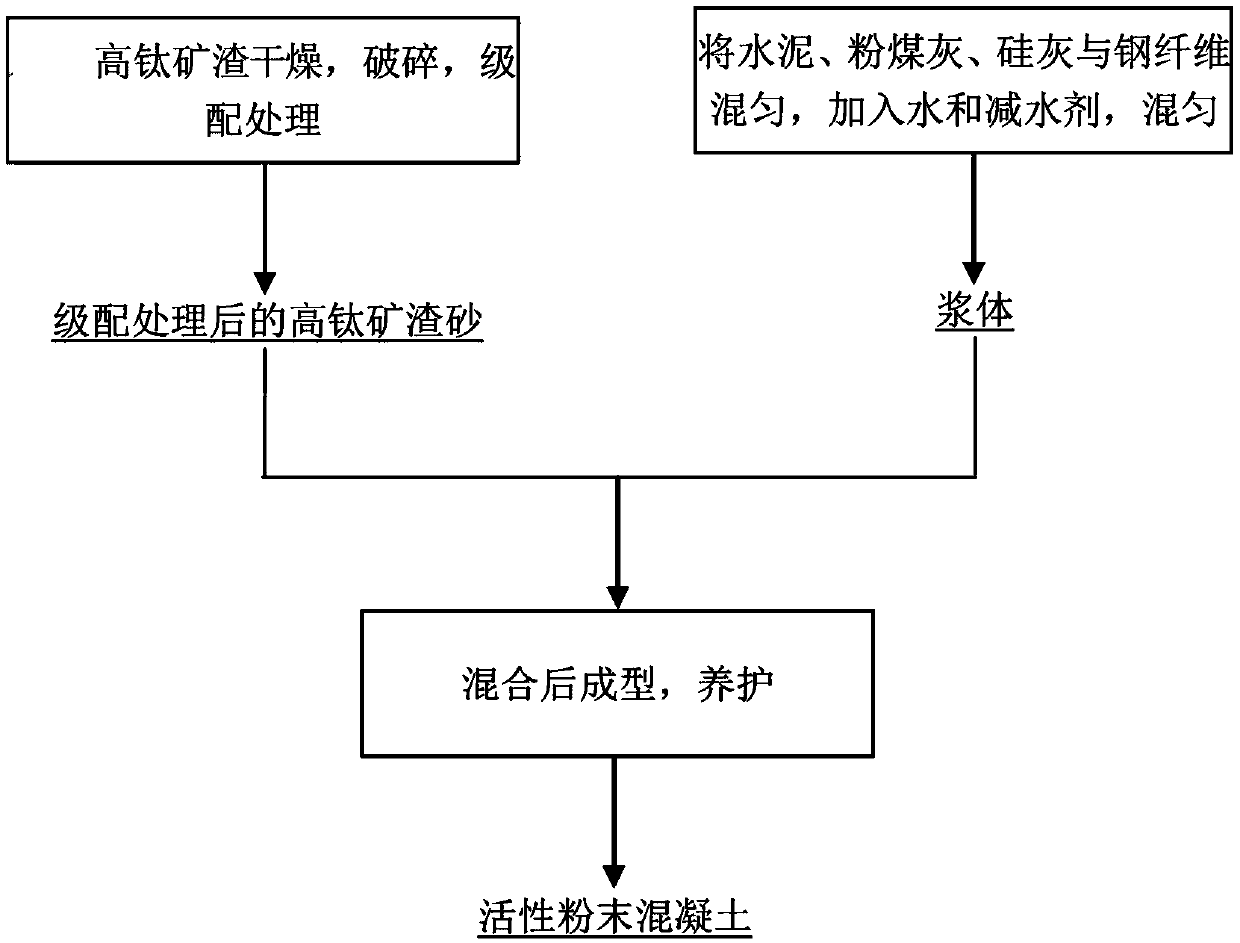

[0026] One aspect of the present invention provides a method for preparing high titanium slag sand active powder concrete. In an exemplary embodiment of the high-titanium slag sand active powder concrete preparation method of the present invention, the preparation method may include:

[0027] Step S01, drying, crushing, screening, and gradation design of the high-titanium slag to obtain the high-titanium slag sand after the gradation design.

[0028] In this embodiment, the high-titanium slag sand includes: TiO 2 16%~23%, SiO 2 15%~23%, CaO 17%~25%, Al 2 o 3 18%~22%, MgO 6%~9%, Fe 2 o 3 4% to 7%, others are some unavoidable impurities. The high-titanium slag is natural-dried or equipment-dried high-titanium slag, the particles of the high-titanium slag have stable crystallization, low glass phase content, good circularity, and almost no needle-like particles. The high-titanium slag is used as aggregate, and will not cause poor durability due to alkali-aggregate react...

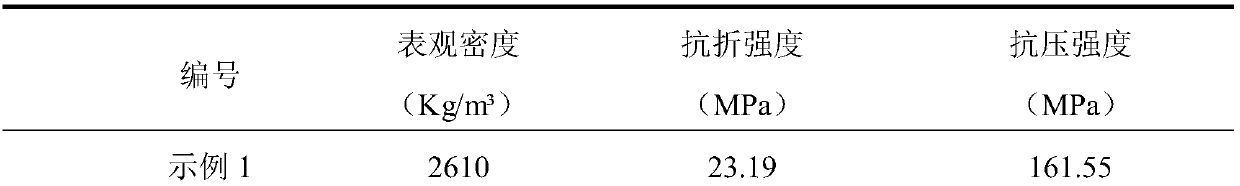

example 1

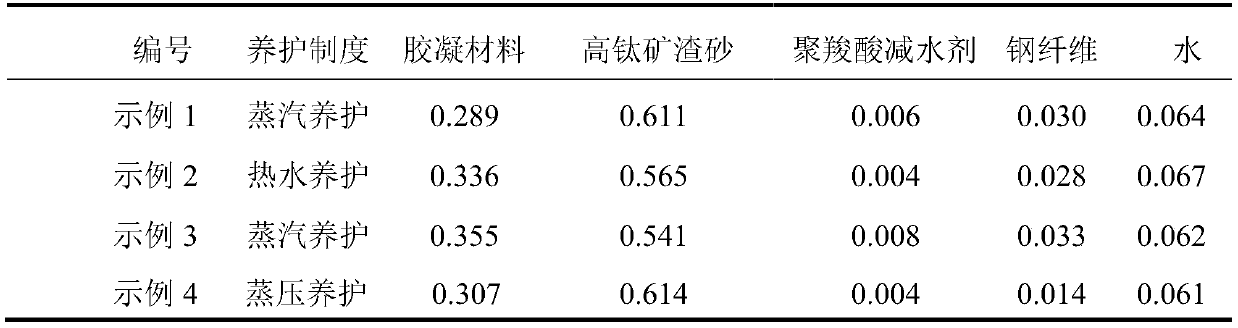

[0047] A kind of high-titanium slag-sand active powder concrete, the high-titanium slag sand, 17.4 parts of cement, 8.7 parts of fly ash, 2.8 parts of silica fume, 3.0 parts of steel fiber, 0.6 parts of Prepared from polycarboxylate water reducer and 6.4 parts of water.

[0048] Preparation methods include:

[0049] 1) After drying the high-titanium slag in an oven at 105°C, crush it into a particle size of less than 1.18mm in a crusher. Then sieve into three grades of 1.18mm-0.6mm, 0.6mm-0.3mm, and 0.3mm-0.15mm for later use.

[0050] 2) In parts by mass, 61.1 parts of high-titanium slag sand, 17.4 parts of cement, 8.7 parts of fly ash, 2.8 parts of silica fume, 3.0 parts of steel fiber, 0.6 parts of water reducing agent and 6.5 parts of water are mixed into powder;

[0051] 3) After mixing the powder and steel fiber in step 2 evenly, add water and stir evenly, then slowly add the high-titanium slag sand obtained in step 1, stir, injection molding, vibration compaction;

...

example 2

[0055] A kind of high-titanium slag-sand active powder concrete, which consists of 56.5 parts of high-titanium slag sand, 20.16 parts of cement, 10.08 parts of fly ash, 3.36 parts of silica fume, 2.8 parts of steel fiber, and 0.4 parts of polycarboxylic acid water-reducing agent and 6.7 parts of water.

[0056] Preparation methods include:

[0057] 1) After the high-titanium slag is naturally dried, it is crushed into a particle size of less than 1.18mm in a crusher. Then sieve into three grades of 1.18mm-0.6mm, 0.6mm-0.3mm, and 0.3mm-0.15mm for later use.

[0058] 2) In parts by mass, 56.5 parts of high-titanium slag sand, 20.16 parts of cement, 10.08 parts of fly ash, 3.36 parts of silica fume, 2.8 parts of steel fiber, 0.4 parts of water reducing agent and 6.7 parts of water are mixed into powder;

[0059] 3) After mixing the powder and steel fiber in step 2 evenly, add water and stir evenly, then slowly add the high-titanium slag sand obtained in step 1, stir, injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com