Synthesis method of 1,4-bis(methylsulfonyl) piperazine

A methylsulfonyl group and synthesis method technology, which is applied in the field of synthesis of 1,4-bispiperazine, can solve the problems of battery cycle performance degradation, structural damage, low design value of battery specific capacity, etc., and achieve a mild and stable reaction process, Simple synthetic route and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 43g (0.5mol) of piperazine, 300ml of dichloromethane, and 202g (2mol) of triethylamine into a four-neck flask, cool down to 0°C, add 127g (1.1mol) of methanesulfonyl chloride dropwise, and complete the dropwise addition within 1 hour. Start to raise the temperature to 8°C, and keep the temperature for 4 hours. After the reaction, wash with water, dry, and concentrate to obtain the crude product, which is then recrystallized with DMC to obtain 108.6 g of the product with a yield of 89.75%.

[0019] The purity of the product detected is 96.9%, and the density is 48.86g / cm 3 , the boiling point is 420.6°C (760mmHg).

Embodiment 2

[0021] Add 43g (0.5mol) of piperazine and 300ml of dichloroethane into a four-neck flask, add 212g (2.1mol) of triethylamine, lower the temperature to 0°C, add dropwise 114.5g (1mol) of methanesulfonyl chloride, dropwise for 1.2h After the addition was completed, the temperature was raised to 5°C, and the reaction was kept for 5 hours. After the reaction was completed, the crude product was washed, dried, and concentrated to obtain a crude product, which was then recrystallized with DMC to obtain 102.9 g of the product, with a yield of 85%.

[0022] The purity of the product detected is 95.3%, and the density is 48.33g / cm 3 , the boiling point is 428.7°C (760mmHg).

Embodiment 3

[0024] Add 43g (0.5mol) of piperazine and 300ml of chloroform into a four-neck flask, add 253g (2.5mol) of triethylamine, cool down to 0°C, add 143g (1.25mol) of methanesulfonyl chloride dropwise, and complete the dropwise addition in 1.1h. Start to raise the temperature to 10°C, and keep the temperature for 4.5 hours. After the reaction, wash with water, dry, and concentrate to obtain the crude product, which is then recrystallized with DMC to obtain 105.7 g of the product, with a yield of 87.35%.

[0025] The purity of the product obtained by testing is 96.2%, and the density is 48.51g / cm 3 , the boiling point is 423.4°C (760mmHg).

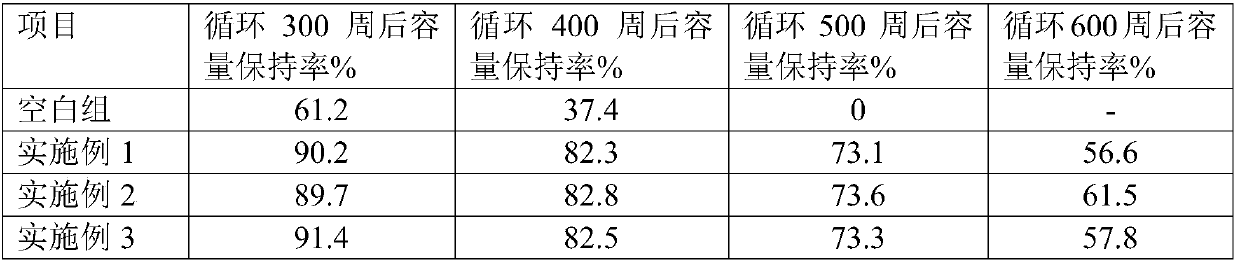

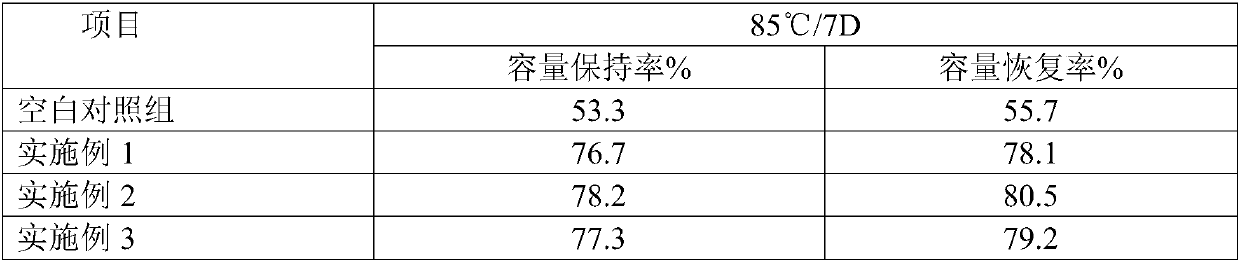

[0026] 2. Performance test

[0027] After the assembled battery of the present invention is tested for cycle performance, lithium cobalt oxide is used as the positive electrode material, mesophase carbon microspheres are used for the negative electrode, the current collectors of the positive and negative electrodes are distributed as aluminum f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com