UV-LED inkjet ink for PVC leather printing and preparation method thereof

A UV-LED and inkjet ink technology, applied in the direction of ink, application, dyeing, etc., can solve the problems of gloss loss, oily leather surface, high VOC content, etc., to improve pattern clarity, avoid wrinkling, and reduce flow Diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples. Those skilled in the art should understand that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

[0036] In the examples, the experimental methods used are conventional methods unless otherwise specified, and the materials and reagents used are commercially available unless otherwise specified.

[0037] (1) Preparation of itaconate modified epoxy soybean oil

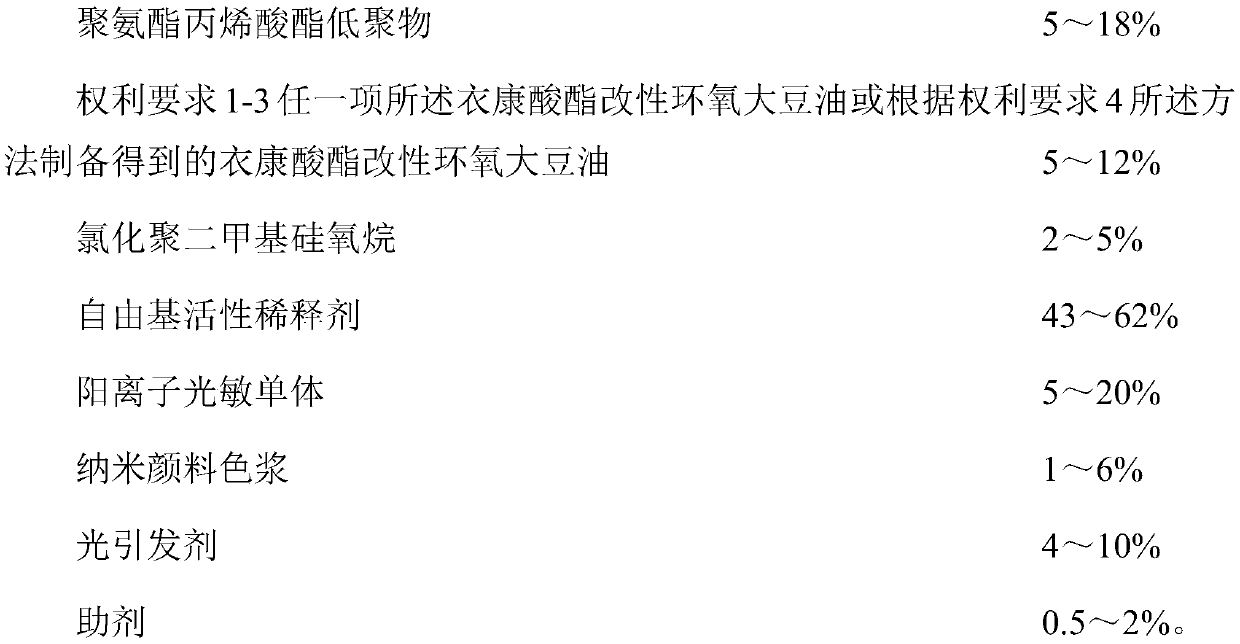

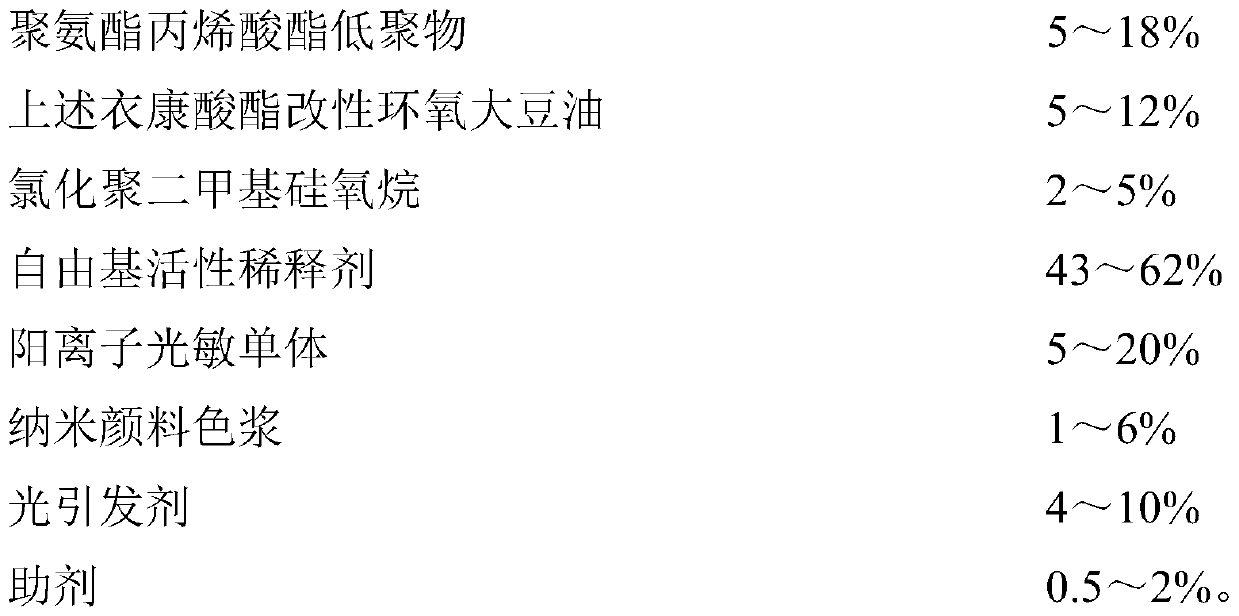

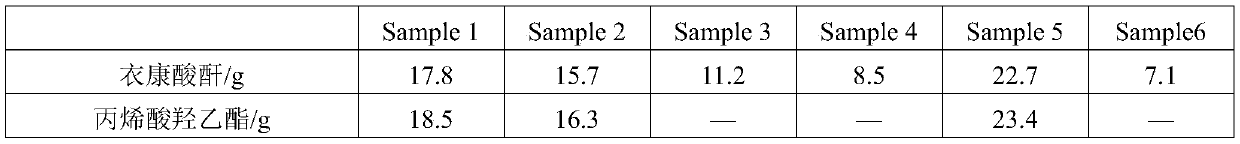

[0038] The synthetic formula of the itaconate-modified epoxy soybean oil of the present embodiment is as shown in table 1, and the preparation method of itaconate-modified epoxy soybean oil specifically comprises the steps:

[0039] S1. Put itaconic anhydride, hydroxyacrylate, p-hydroxyanisole and N-dimethylaminopyridine in the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com