Strain capable of producing transglutaminase

A technology of glutamine and transaminase, applied in the field of genetic engineering, can solve the problems of low fermentation enzyme activity, limited application value, and limited industrial production capacity, and achieve the effect of simplifying the extraction process and shortening the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

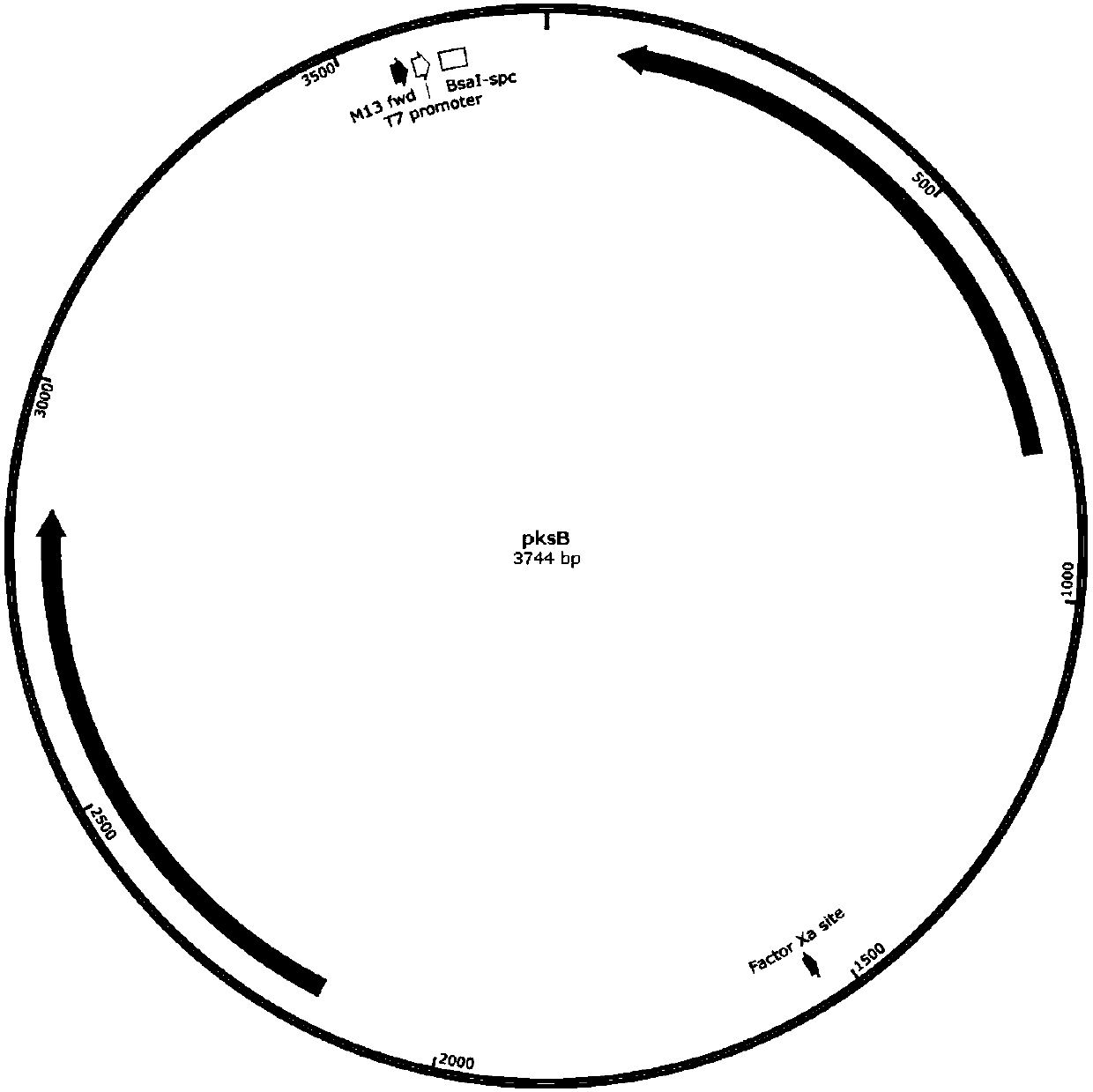

[0035] Embodiment 1: the construction of pksB plasmid

[0036] pksB( figure 1 shown) is a thermosensitive E.coli / B.subtilis shuttle plasmid. The plasmid includes a temperature-sensitive origin of replication (active at 30°C) and an erythromycin resistance gene (ermC). The resistance of the resistance gene in E.coli is 300ug / ml, and in B.subtilis The resistance in is 5ug / ml. At 37°C, the origin of replication on the plasmid is inactivated, and the plasmid is integrated into the designated site of the host bacterial genome, and is screened with a certain concentration of erythromycin.

[0037] The construction method of pksb plasmid is as follows. Plasmid pUC57-KS-erm (synthesized by Genscript Company, sequence SEQ ID NO: 1) was double-digested with BglII, and the 3.8kbp fragment was recovered and purified, self-ligated with T4 ligase (purchased from New England Biolabs), and the cloned plasmid was It is pksB. This plasmid was transformed into E. coli TOP10 for propagation ...

Embodiment 2

[0038] Embodiment 2: the construction of protease-deficient Bacillus subtilis bacterial strain

[0039] The subtilisin E (AprE), neutral protease E (NprE) and sigF genes were knocked out using a single-crossover Campbell-type mechanism in a sequential manner. The details are as follows: use BglII endonuclease to treat the plasmid pksB, and then use CIP enzyme to prevent self-ligation after digestion and recovery to obtain the linear fragment of the vector; respectively amplify the homology of about 500 bp flanking each gene to be knocked out by PCR method area. Using a single colony of Bacillus subtilis as a template, PCR reaction primers were synthesized by Genscript, wherein pksb-apr_R1 / pksb-apr_F2, pksb-npr_R1 / pksb-npr_F2 and pksb-sig_R1 / pksb-sig_F2 were used for PCR reaction amplification apr, The flanking sequences of npr and sigF genes, the primer sequences are as follows:

[0040] The primers for amplifying the upstream sequence of the apr gene are:

[0041] pksb-apr...

Embodiment 3

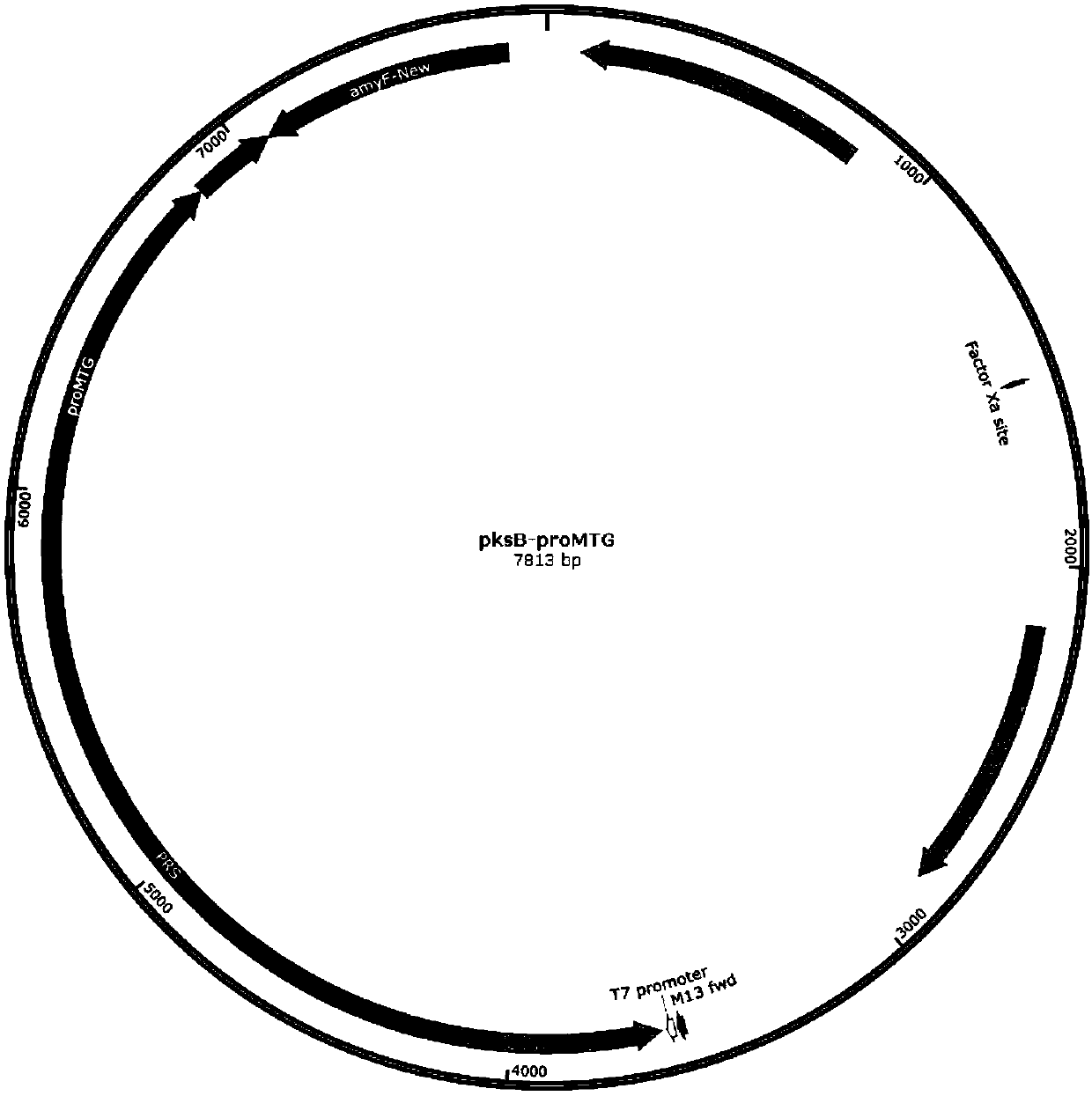

[0069] Embodiment 3: the construction of MTG production bacterial strain

[0070] The fragments of 500 bp upstream and downstream of the amyE gene were integrated into the plasmid pksB to construct the plasmid pksB-amyFR. The specific method is as follows: the plasmid pksB( figure 1 ) was digested with KpnI-EcoRI to recover and purify the 3711bp fragment pksB-KpnI-EcoRI; use primers pksb-amyF-F / pksb-amyF-R and pksb-amyR-F / pksb-amyR-R to amplify the insert respectively The upstream and downstream homology arm sequences of amyE are amyF and amyR; then using overlapping PCR technology, the upper and lower primers pksb-amyF-F / pksb-amyR-R are amplified to connect the fragments to obtain the gene fragment amyFR; use KpnI-EcoRI to digest The amyFR fragment was then ligated with the linearized vector pksB-KpnI-EcoRI through T4 ligase (purchased from New England Biolabs), and the cloned plasmid was pksB-amyFR. The plasmid was transferred into E.coli TOP10 for propagation and served a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com