High-organic matter formula nutritive soil and preparation method thereof

A technology of organic matter and nutritious soil, applied in botany equipment and methods, organic fertilizers, planting substrates, etc., can solve the problems of large volume of domestic sludge, low resource utilization value, low social acceptance, etc., and promote the disposal work , Realize the recycling of resources and the effect of sustained release of fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

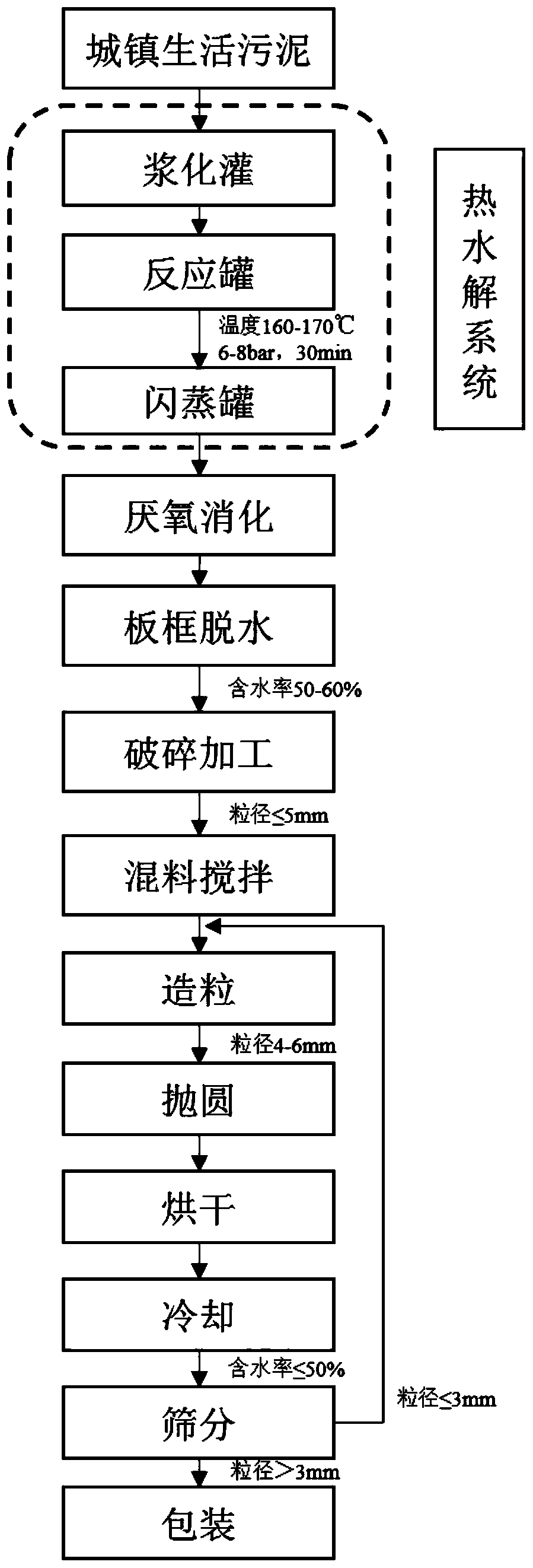

[0039] A preparation method for producing high-organic formula nutrient soil using urban domestic sludge. The sludge comes from the sludge treatment center of the Gaobeidian Reclaimed Water Plant in Chaoyang District, Beijing.

[0040] (1) After collecting the sludge produced by the urban domestic sewage plant, it first enters the thermal hydrolysis treatment system: the sludge enters the slurry tank through the sealed pipeline to quench and temper, until the solid content of the sludge is 16wt%; in the reaction tank Keep the temperature at 165-170℃ and react at 6bar high pressure for 30min, then flash to release the pressure and cool to 45℃ under normal pressure. The killing rate of pathogenic bacteria in this process reaches 99.9%, and the sludge is harmless.

[0041] (2) After the thermal hydrolysis of the sludge is completed, the solid content of the obtained sludge is adjusted to 10wt%, and then pumped to the anaerobic digestion reactor for anaerobic digestion at 40°C for 24 ...

Embodiment 2

[0052] The difference from Example 1 is:

[0053] The ingredient weight ratio of the high organic matter formula nutrient soil includes: 60 wt% of sludge product, 30 wt% of potassium humate, 5 wt% of ammonium sulfate, and 5 wt% of bentonite, which are uniformly mixed. The quality reaches moisture content ≤50%, particle size 3-6mm, organic matter 47.5%, total nitrogen, phosphorus and potassium nutrients 9.54% (of which, total nitrogen 3.07%, total phosphorus 2.30%, total potassium 4.17%).

Embodiment 3

[0055] The difference from Example 1 is:

[0056] The ingredient weight ratio of the high organic matter formula nutrient soil includes: 80% by weight of sludge product, 15% by weight of humic acid, and 5% by weight of ammonium sulfate, which are uniformly mixed. The quality reaches moisture content ≤50%, particle size 3-6mm, organic matter 47.6%, total nitrogen, phosphorus and potassium nutrients 8.01% (of which, total nitrogen 3.98%, total phosphorus 3.76%, and total potassium 0.27%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com