Oxidized molybdenum disulfide modified flat nano filtration membrane as well as preparation method and application thereof

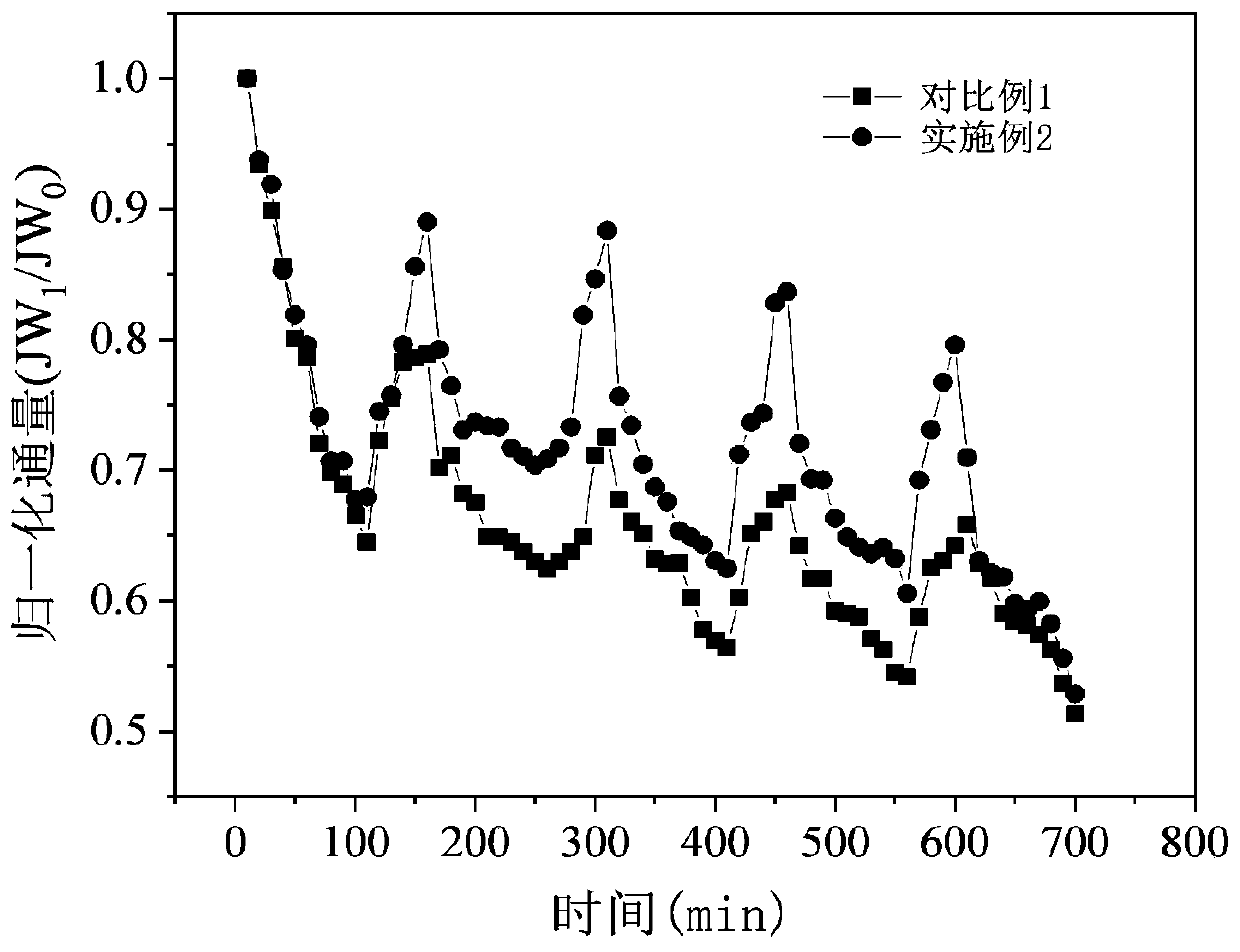

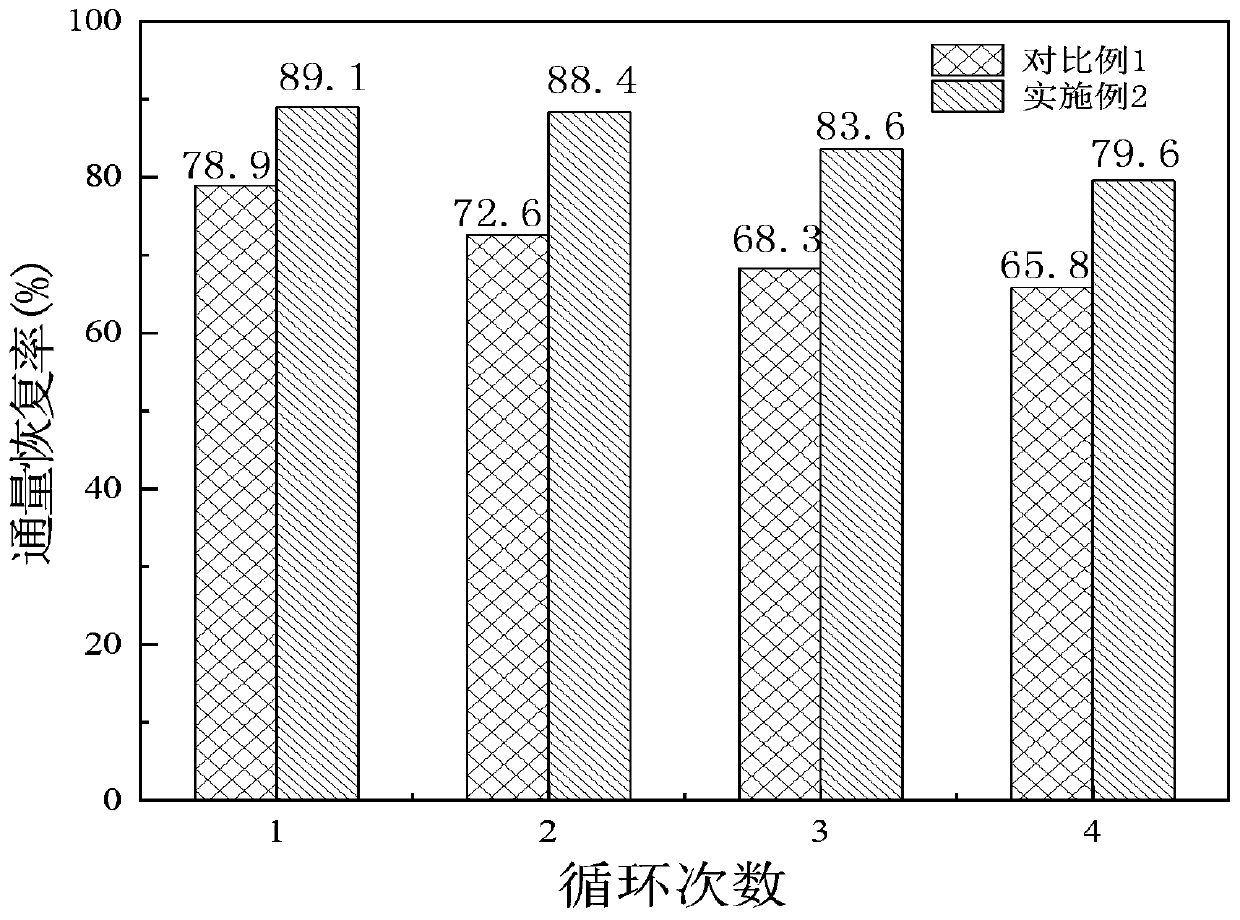

A technology of oxidizing molybdenum disulfide and nanofiltration membrane, applied in the field of nanofiltration membrane, can solve the problems of decreasing pure water flux and removal rate, reducing membrane operating life, increasing use cost, etc., achieving excellent hydrophilicity, improving Density, the effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of described molybdenum disulfide oxide preferably comprises the following steps:

[0038] Molybdenum disulfide and sodium nitrate are first mixed to obtain a mixture;

[0039] The concentrated sulfuric acid is mixed with the mixture for the second time to obtain a dispersion;

[0040] The dispersion liquid and potassium permanganate are mixed for the third time, and an oxidation reaction occurs to obtain a molybdenum disulfide dispersion liquid;

[0041] The oxidized molybdenum disulfide dispersion is removed, filtered and dried to obtain oxidized molybdenum disulfide.

[0042] In the present invention, molybdenum disulfide and sodium nitrate are first mixed to obtain a mixture. In the present invention, the mass ratio of molybdenum disulfide to sodium nitrate is preferably 2.8-3.2:1, more preferably 3:1. The present invention does not have any special limitation on the first mixing, and it is enough to use the process well known to those skille...

Embodiment 1~4 and comparative example 1

[0067] One, prepare oxidized molybdenum disulfide according to the following steps:

[0068] 3g of molybdenum disulfide and 1g of sodium nitrate are mixed to obtain a mixture;

[0069] 50ml of concentrated sulfuric acid with a mass concentration of 98% was mixed with the mixture, and stirred at a speed of 450r / min for 12h to obtain a dispersion;

[0070] Under the condition of ice bath, add 6g of potassium permanganate to the dispersion liquid to carry out the first oxidation reaction, and then carry out the second oxidation reaction in an oil bath at 35°C after 30 minutes of reaction time, and after 3 hours of reaction, oxidative disulfide is obtained Molybdenum dispersion; where the oil bath is accompanied by stirring.

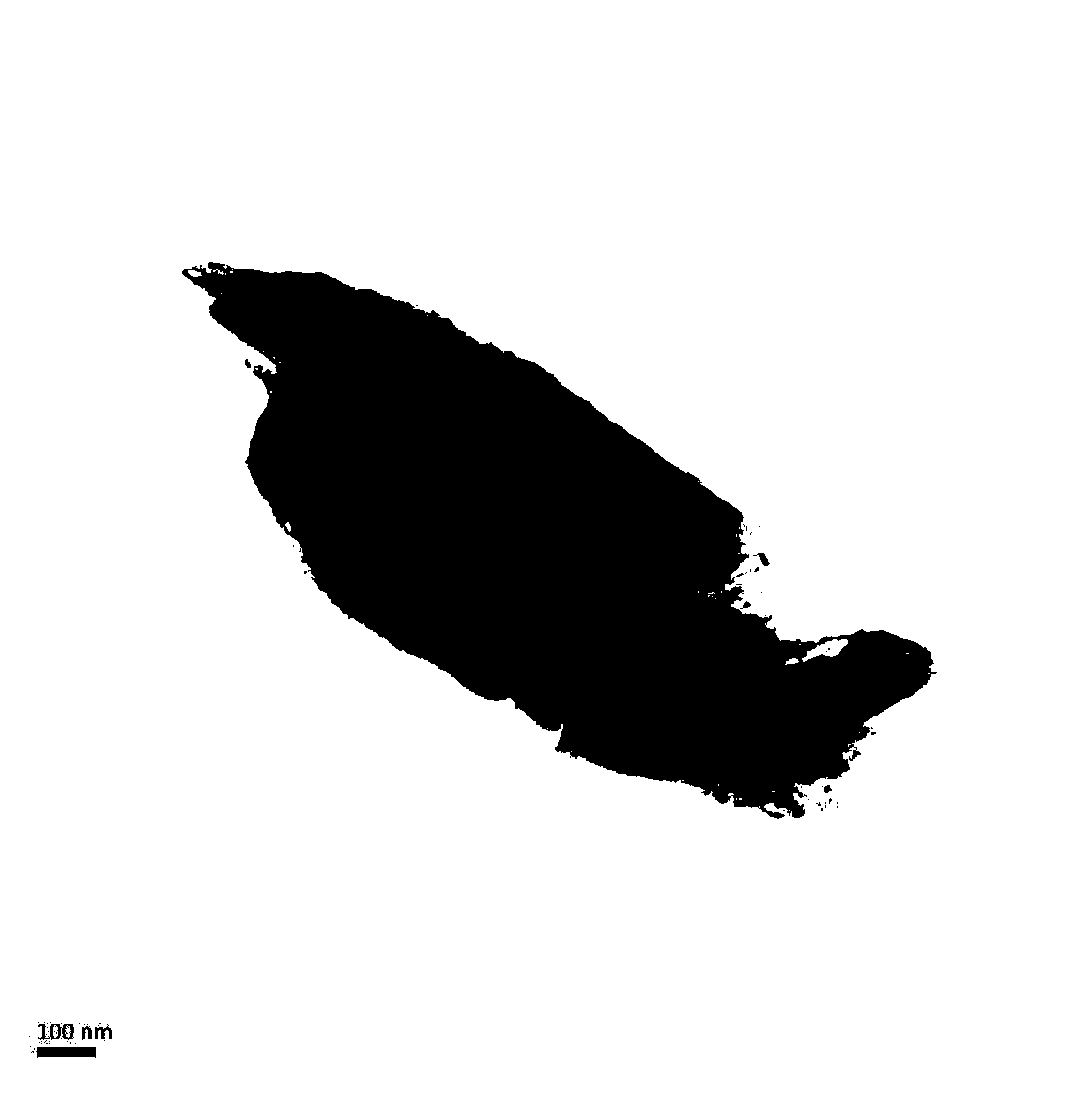

[0071] The oxidized molybdenum disulfide dispersion is sequentially removed from impurities, filtered and dried to obtain oxidized molybdenum disulfide; the removal of impurities includes the following steps: under stirring conditions, the oxidized molybden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap