System and method for extracting sulfur from sulfur-containing foam in coking plant

A technology for coking plant and foam is applied in the field of extracting sulfur from sulfur-containing foam in a coking plant, which can solve the problems of failure to meet sulfur quality requirements, serious environmental pollution, and low sulfur content in sulfur residues, and achieve large-scale continuous production and sulfur High-purity, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Example 1 A system for extracting sulfur from sulfur-containing foam in a coking plant

Embodiment 11

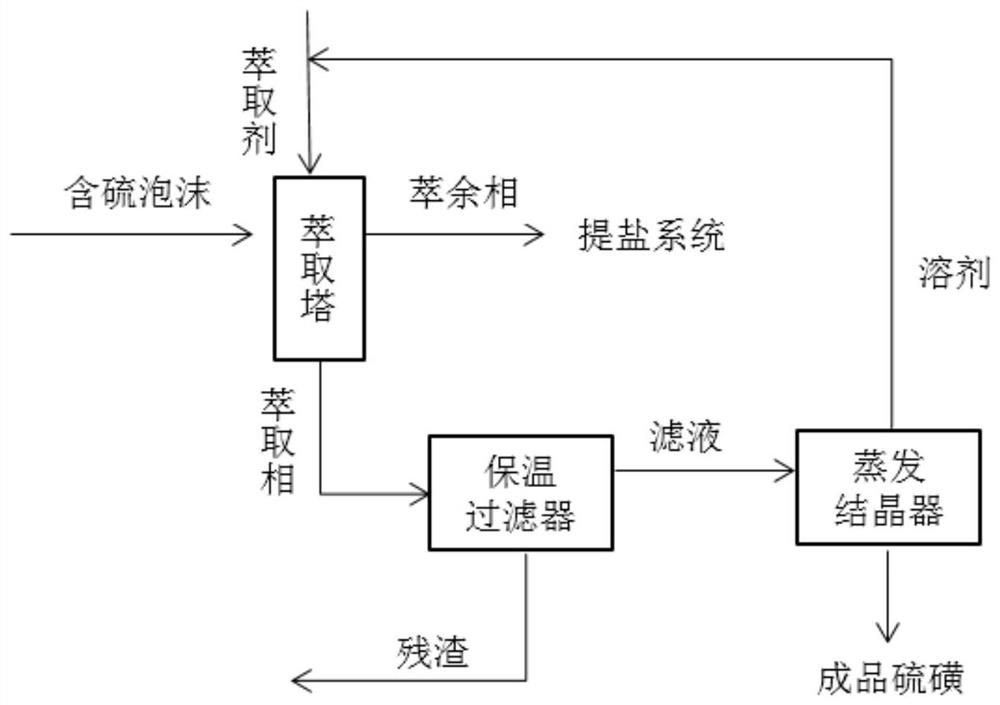

[0125] The system for extracting sulfur from the sulfur-containing foam in the coking plant described in this embodiment is as follows: figure 1 shown, including:

[0126] (1) Extraction unit

[0127] The extraction unit is an extraction tower, and the extraction tower includes two inlets and two outlets, and the outlets include an extraction phase outlet and a raffinate phase outlet. Inlets include sulfur foam feed ports and extractant feed ports. The extraction tower also includes a stirring paddle with blades driven by a geared motor.

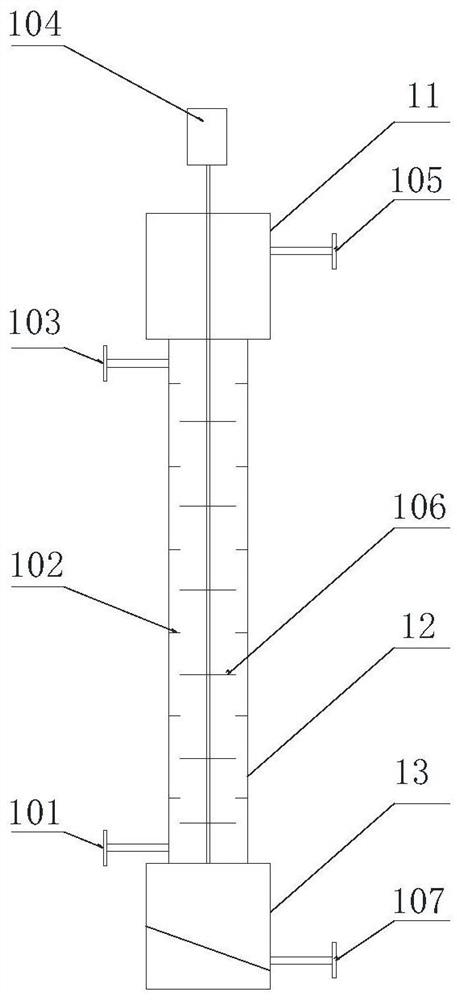

[0128] In this embodiment, specifically, the structure of the extraction tower is as follows figure 2 As shown, the extraction tower is a liquid-liquid continuous extraction tower, including a tower body and a motor 104, and the tower body includes an upper clarification section 11, a mixing section 12 and a lower clarification section 13 from top to bottom, and the mixing section 12 is Cylinder structure, the inner wall of the mixing sec...

Embodiment 12

[0141] The system for extracting sulfur from the sulfur-containing foam in the coking plant described in this example is similar to Example 1.1, wherein, in this example, the process diagram of the extraction tower used is as follows Figure 4 shown. The interior of the tower includes an upper clarification section 301 , a mixing section 302 and a lower clarification section 303 from top to bottom. The upper and lower ends of the mixing section are respectively equipped with an upper flange and a lower flange. The upper clarification section is formed between the upper flange and the top of the tower, which is used to clarify the light liquid. The lower clarification section is formed between the lower flange and the bottom of the tower. To clarify heavy liquid. The inner wall of the mixing section 302 is provided with a fixed ring with a central opening. The fixed ring divides the mixing section of the tower body into a series of extraction chambers. A rotating disk is insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com