High-adsorption low-powder-falling zero-pollution 3A molecular sieve and forming process and application thereof

A molding process, molecular sieve technology, applied in molecular sieves and alkali exchange compounds, A-type crystalline aluminum silicate zeolite, separation methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

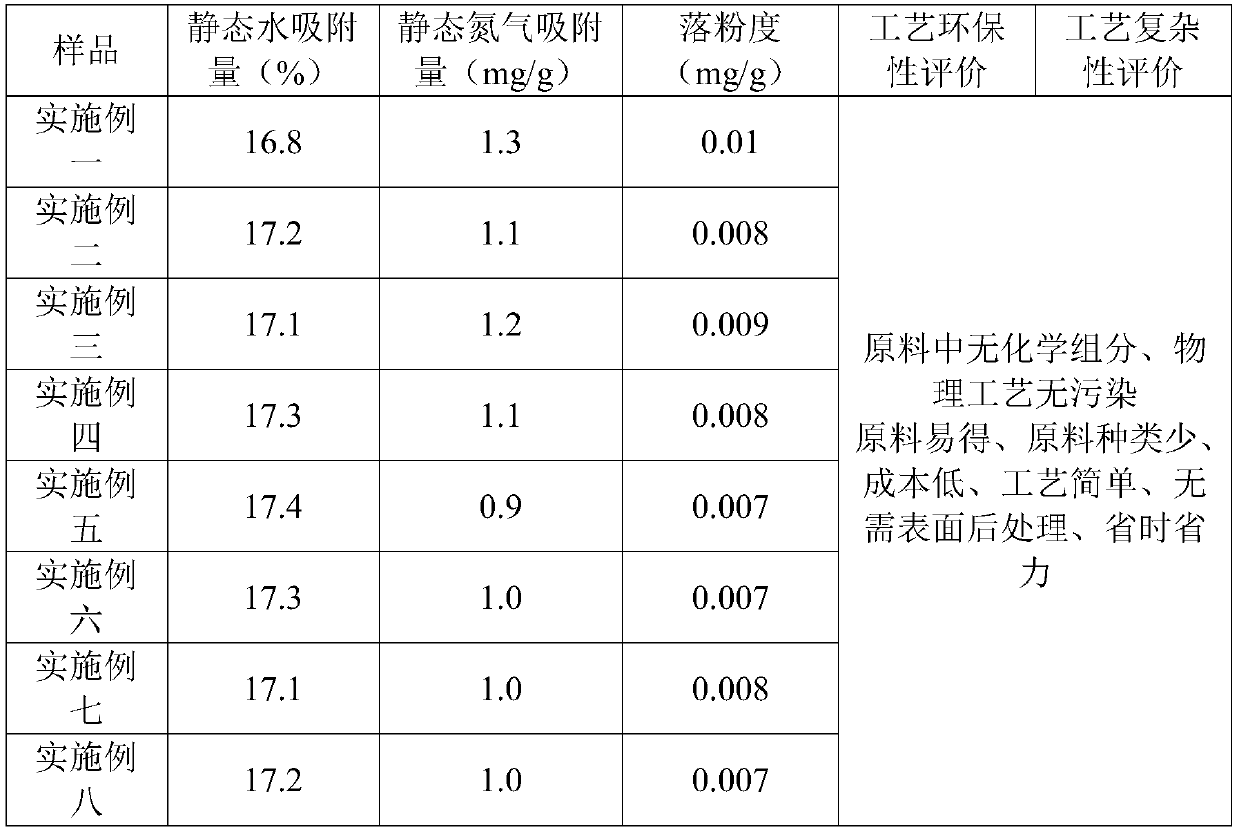

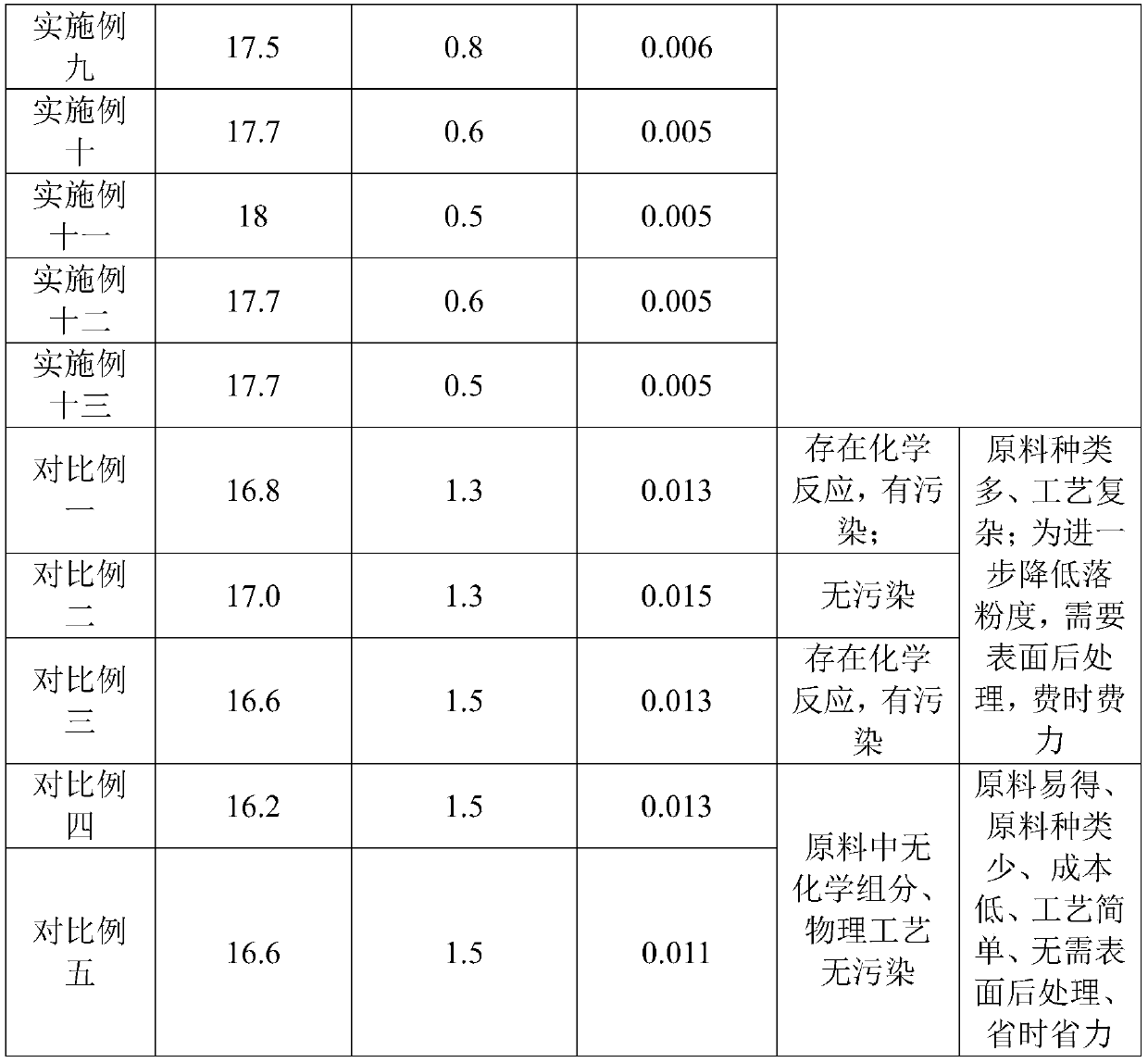

Examples

Embodiment 1

[0047] A 3A molecular sieve with high adsorption and low powder falling and zero pollution is prepared by the following method:

[0048] (1) Ingredients: weigh 60 parts of 3A raw material powder, 40 parts of clay, and 3 parts of high clay according to parts by weight. Both the clay and the high clay are made of attapulgite. The viscosity of the clay is 1700mpa s, and the viscosity of the high clay is 2000mpa s;

[0049] (2) Mix 3A raw material powder and clay evenly to obtain blend I;

[0050] (3) The blend I is dropped into the granulator, the adjusting rotating speed is 30r / min, the water mist spraying flow rate is 0.75L / min, and granulation obtains spherical particles;

[0051] (4) Stop inputting the blend I, put high clay into the granulator, and polish for 20 minutes to obtain the blend II;

[0052] (5) Calcinate blend II at low temperature, the air inlet temperature is 145°C, the temperature in zone III is 110°C, the temperature in zone II is 105°C, the temperature in ...

Embodiment 2

[0055] A 3A molecular sieve with high adsorption and low powder falling and zero pollution is prepared by the following method:

[0056] (1) Ingredients: weigh 70 parts of 3A raw material powder, 30 parts of clay, and 4 parts of high clay according to parts by weight. Both clay and high clay are made of attapulgite. The viscosity of clay is 1700mpa s, and the viscosity of high clay is 2000mpa s;

[0057] (2) Mix 3A raw material powder and clay evenly to obtain blend I;

[0058] (3) The blend I is dropped into the granulator, the adjusting rotating speed is 40r / min, the water mist spraying flow rate is 0.8L / min, and granulation obtains spherical particles;

[0059] (4) Stop inputting the blend I, put high clay into the granulator, and polish for 25 minutes to obtain the blend II;

[0060] (5) Calcinate blend II at low temperature, the air inlet temperature is 145°C, the temperature in zone III is 110°C, the temperature in zone II is 105°C, the temperature in zone I is 100°C, ...

Embodiment 3

[0063] A 3A molecular sieve with high adsorption and low powder falling and zero pollution is prepared by the following method:

[0064] (1) Ingredients: weigh 65 parts of 3A raw material powder, 35 parts of clay, and 5 parts of high clay according to parts by weight. Both the clay and the high clay are made of attapulgite. The viscosity of the clay is 1700mpa s, and the viscosity of the high clay is 2000mpa s;

[0065] (2) Mix 3A raw material powder and clay evenly to obtain blend I;

[0066] (3) The blend I is dropped into the granulator, the adjusting rotating speed is 40r / min, the water mist spraying flow rate is 1.0L / min, and granulation obtains spherical particles;

[0067] (4) Stop inputting blend I, put high clay into the granulator, polish for 30 minutes, and obtain blend II;

[0068] (5) Calcinate blend II at low temperature, the air inlet temperature is 150°C, the temperature in zone III is 110°C, the temperature in zone II is 105°C, the temperature in zone I is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com