A flash vacuum desolventizer

A flash desolventization and desolventization machine technology, which is applied in the protein composition of vegetable seeds, food forming, food science, etc., can solve the problems of low system integration, reduced quality of output, and long heating time. Achieve the effects of improving soluble protein index, improving product quality, and shortening heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

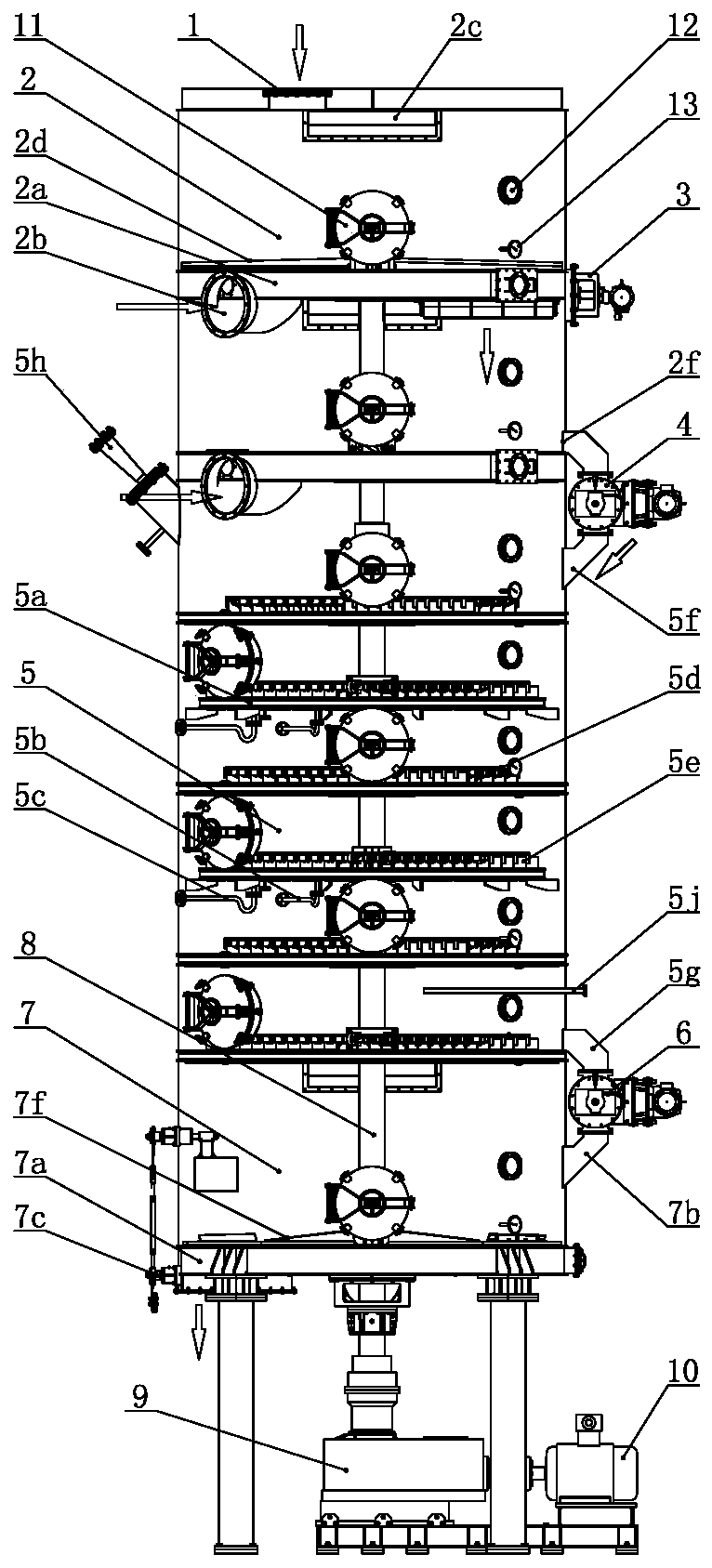

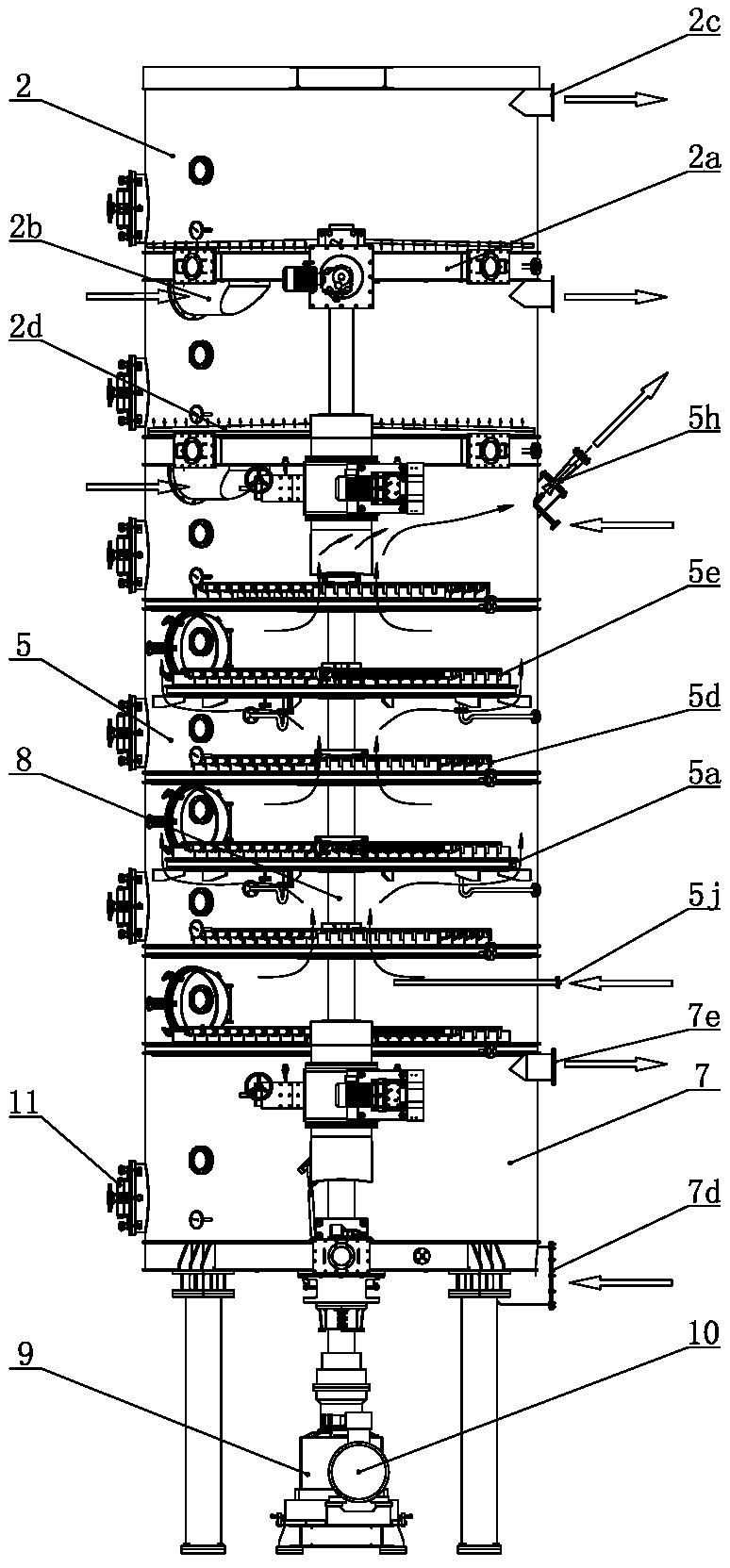

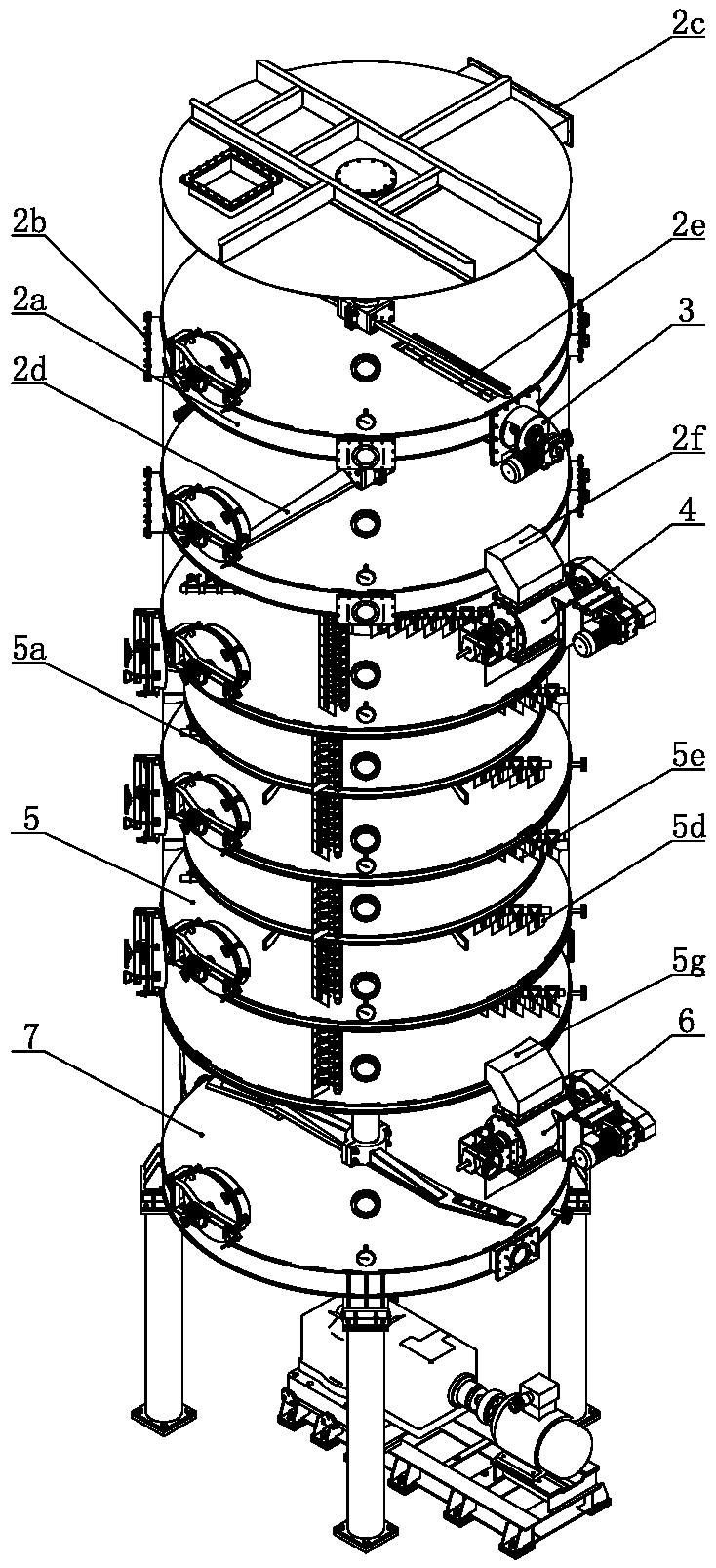

[0032] Such as Figure 1 to Figure 4 As shown, the flash vacuum desolventizer of the present invention comprises a vertical cylinder, the top of the cylinder is provided with a total feed port 1, and the inner cavity of the cylinder is sequentially provided with a flash desolventization section, a vacuum The desolventization section and the drying and cooling layer 7; the flash desolventization section uses superheated solvent steam to perform flash desolventization on the wet meal.

[0033] The high-soluble wet meal enters the inner cavity of the cylinder from the total feed port 1 at the top of the cylinder, and first passes through the flash desolventization section, where the superheated solvent steam is used as the desolventization heat and mass transfer carrier to flash the wet meal Desolventization, so that the high-moisture-content meal becomes low-content meal, and then the low-content meal becomes medium-temperature meal. The medium-temperature meal enters the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com