Preparation method for polyurethane prepolymer

A polyurethane prepolymer, polyisocyanate technology, applied in the direction of polyurea/polyurethane adhesive, sustainable manufacturing/processing, adhesive type, etc., can solve the problem of unstable polyurethane prepolymer, low production efficiency, irritation, etc. Great odor and other problems, to achieve the effect of reducing viscosity, low fog value and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

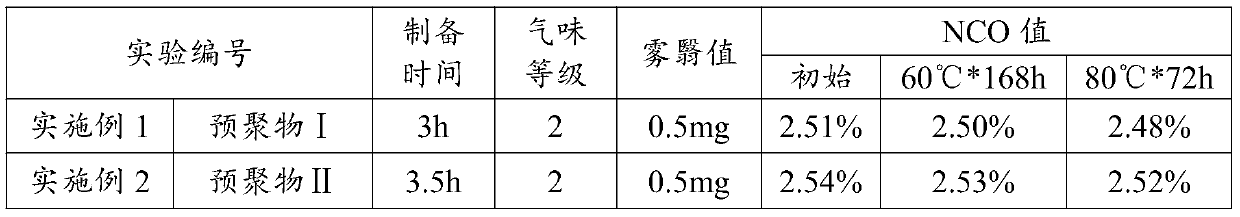

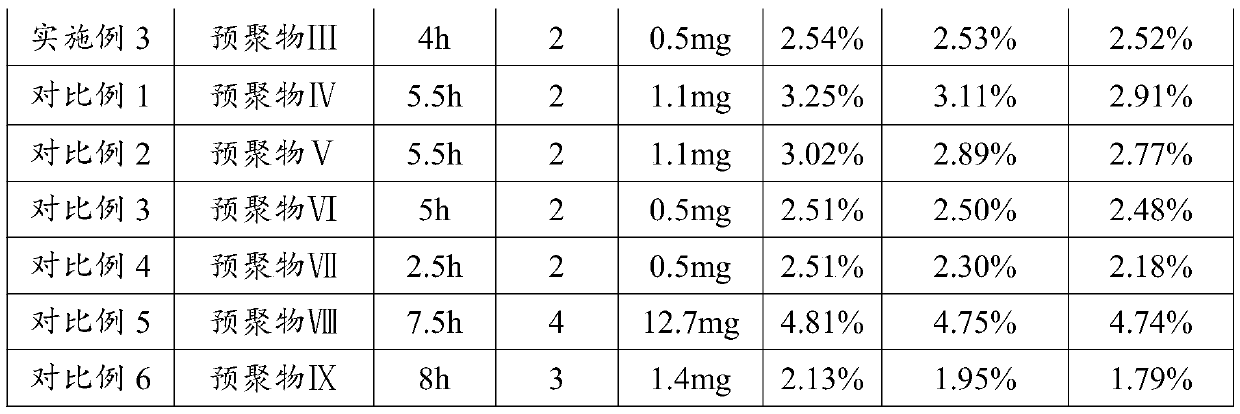

[0034] Prepolymer Ⅰ: Add 24.5 parts of polyether diol Tdiol-2000 (molecular weight 2000), 40.2 parts of polyether triol F3128 (molecular weight 6000), and 11.144 parts of diisooctyl phthalate into a dry three-necked flask , 0.01 part of toluenesulfonyl isocyanate, stirred and mixed in vacuum at 50℃~55℃ for 20min, wherein the vacuum degree ≤-0.09MPa. Nitrogen pressure relief, where the nitrogen purity is ≥95%, add 13 parts of diphenylmethane-4,4'-diisocyanate and 0.002 parts of dibutyltin dilaurate to the reaction mixture, and the addition is controlled within 5 minutes, vacuum Stir and heat up, wherein the heating rate is 10°C / 10min, the vacuum degree is ≤-0.09MPa, and at a temperature of 65°C±2°C, after 1.5 hours of reaction, the NCO reaches the preset target ≤2.95%, and the heating and heat preservation equipment is turned off. Nitrogen pressure relief, wherein the nitrogen purity is ≥95%, add 11.144 parts of di-isooctyl phthalate to the reaction mixture at room temperature,...

Embodiment 2

[0037] Prepolymer II, add 22 parts of polyether diol Tdiol-3000 (molecular weight 3000), 48.5 parts of polyether triol GEP-330N (molecular weight 5000), 5.5 parts of diisophthalic acid in a dry three-necked flask Octyl ester, 0.01 part of toluenesulfonyl isocyanate, stirred and mixed under vacuum at 50℃~55℃ for 20min, wherein the degree of vacuum is ≤-0.09MPa. Nitrogen pressure relief, wherein the nitrogen purity is ≥ 95%, add 13 parts of diphenylmethane-4,4'-diisocyanate and 0.002 parts of dibutyltin dilaurate to the reaction mixture, the addition is controlled within 5 minutes, and vacuum stirring Heating, where the heating rate is 10°C / 10min, the vacuum degree is ≤-0.09MPa, and the temperature is 65°C±2°C, react for 1.5 hours, and the NCO reaches the preset target ≤2.85%, turn off the heating and heat preservation equipment. Nitrogen pressure relief, wherein the nitrogen purity is ≥95%, add 11 parts of di-isooctyl phthalate to the reaction mixture at room temperature, stir ...

Embodiment 3

[0040]Prepolymer III: Add 26.7 parts of polyether diol Tdiol-2000 (molecular weight 2000), 42.8 parts of polyether triol F3135 (molecular weight 5000), and 5 parts of diisooctyl phthalate into a dry three-necked flask The mixture with dioctyl terephthalate (V:V=1:1), 0.03 parts of toluenesulfonyl isocyanate, stirred and mixed in vacuum at 50℃~55℃ for 20min, wherein the vacuum degree≤-0.09MPa. Nitrogen pressure relief, wherein the nitrogen purity is ≥ 95%, 10.467 parts of hexamethylene diisocyanate and 0.003 parts of dibutyltin diacetate are respectively added to the first reaction mixture, the addition is controlled within 5 minutes, and the temperature is raised under vacuum stirring, wherein the heating rate is 10°C / 10min, vacuum degree ≤-0.09MPa, at 65°C±2°C, after 1.5 hours of reaction, NCO reaches the preset target ≤3.56%, turn off the heating and heat preservation equipment. Nitrogen pressure relief, where the nitrogen purity is ≥95%, add 15 parts of a mixture of di-octy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com