Polyurethane foam material and preparation method thereof, and application in wound dressing

A technology of polyurethane foam and water-based polyurethane, applied in the field of polyurethane foam materials, can solve problems such as unfavorable dressing replacement, difficult wound slough distinction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

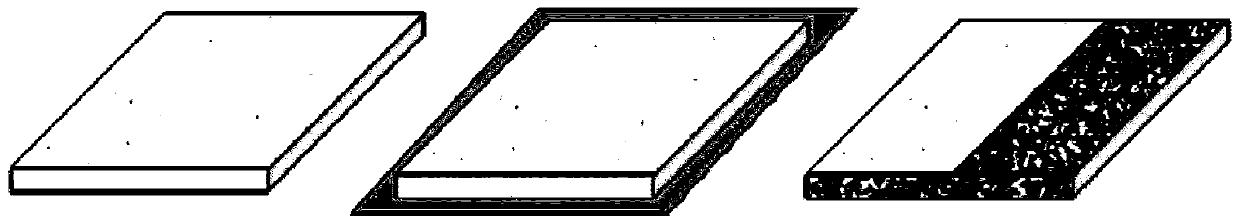

Image

Examples

Embodiment 1

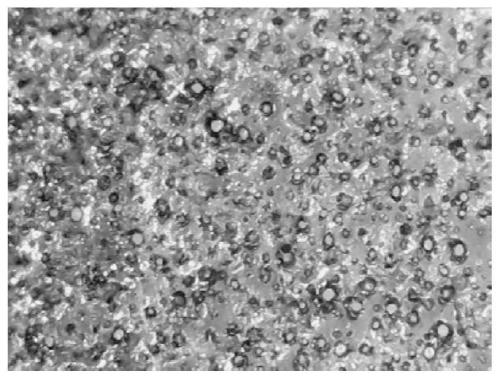

[0098] Add 90g to a precisely graduated 1L plastic beaker 3458, 30g of the above-mentioned synthetic nonionic aqueous polyurethane emulsion A, 6g STA, 1.2g SR, then use an egg beater to stir at a high speed at 1000rpm in an air atmosphere for 10min, to obtain a slurry with fluidity and rich foam, and no large cells greater than 1mm by visual inspection, and the volume of the aqueous polyurethane dispersion slurry rises to 550mL, the density of the foam slurry is 231.2g / L.

[0099] Add 12g of sodium alginate aqueous solution with a concentration of 2.5wt% to the above foam slurry, and stir evenly to obtain a foam slurry with a viscosity of 15000 cps. In order to detect the stability of the high-viscosity foam slurry, the height change of the slurry in the beaker before and after standing at room temperature for 10 minutes was recorded, and the results showed that the height of the foam slurry after standing for 10 minutes was 95% of the initial height.

[0100] Afterwards...

Embodiment 2

[0103] Add 68g to a precisely graduated 1L plastic beaker 3458, 40g 7396, 22g 5318, 6g STA, 1.2g SR, then use an egg beater to stir at a high speed at 1500rpm in an air atmosphere for 5 minutes to obtain a slurry with fluidity and rich foam, and there are no large cells greater than 1mm by visual inspection, and the volume of the aqueous polyurethane dispersion slurry rises to 560mL, the density of the foam slurry is 227.1g / L.

[0104] Add 6g of 5wt% sodium alginate aqueous solution to the above foam slurry, and stir evenly to obtain a foam slurry with a viscosity of 16500cps. In order to detect the stability of the high-viscosity foam slurry, the height change of the slurry in the beaker before and after standing at room temperature for 10 minutes was recorded, and the results showed that the height of the foam slurry after standing for 10 minutes was 91% of the initial height.

[0105] Afterwards, the above-mentioned viscous foam slurry was scraped onto a TPU film wi...

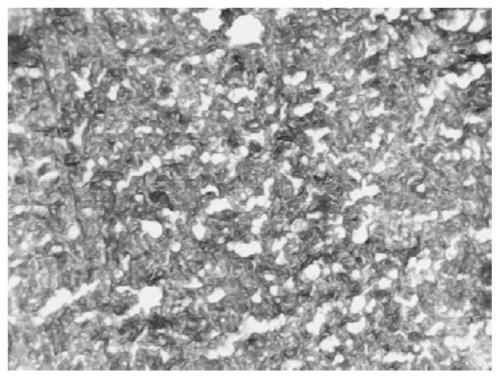

Embodiment 3

[0108] Add 45g to a precisely graduated 1L plastic beaker FD103, 40g 7396, 35g non-ionic water-based polyurethane emulsion A, 6g 188, 2.4g Brij721, and then use an egg beater to stir at 1500rpm in an air atmosphere at high speed for 5 minutes to obtain a fluid and foam-rich slurry, and there are no large cells larger than 1mm by visual inspection. At the same time, the water-based polyurethane dispersion slurry The volume rises to 530mL, then the density of the foam slurry is 240g / L.

[0109] Add 10 g of sodium alginate aqueous solution with a concentration of 2.5 wt % to the above foam slurry, and stir evenly to obtain a foam slurry with a viscosity of 12500 cps. In order to detect the stability of the high-viscosity foam slurry, the height change of the slurry in the beaker before and after standing at room temperature for 10 minutes was recorded, and the results showed that the height of the foam slurry after standing for 10 minutes was 87% of the initial height.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com