Preparation method of lanthanum-cerium modified magnesium oxide composite polishing powder

A composite polishing and magnesium oxide technology, applied in polishing compositions containing abrasives, etc., can solve problems such as consumption, and achieve the effects of saving rare earth resources and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

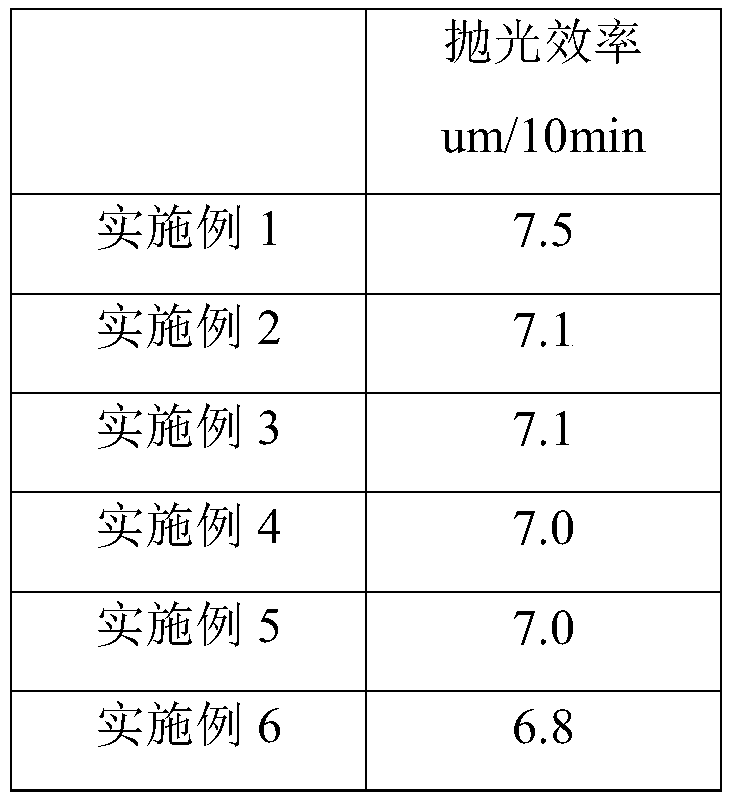

Examples

Embodiment 1

[0039] A preparation method of lanthanum cerium modified magnesium oxide composite polishing powder, which comprises the steps of:

[0040] S1 Fully mix 95mL of 30g / L magnesium chloride solution and 5mL of lanthanum cerium chloride solution (wherein the concentration of lanthanum chloride is 20g / L, and the concentration of cerium chloride is 20g / L) under the condition of stirring at a temperature of 50°C Add 200mL of a mixed solution of sodium fluoride and sodium hydroxide at a speed of 12L / min for precipitation (wherein the concentration of sodium fluoride is 5g / L and the concentration of sodium hydroxide is 90g / L), age for 16 hours, and filter to obtain fluoride Magnesium hydroxide composite precipitation;

[0041] S2 Composite precipitation of fluorinated magnesium hydroxide, dried at 110°C, put into a sagger and put into a shuttle-type industrial kiln for roasting according to the following roasting curve. ℃, roasting for 8h;

[0042] The second stage: at 420 ° C, heat p...

Embodiment 2

[0048] A preparation method of lanthanum cerium modified magnesium oxide composite polishing powder, which comprises the steps of:

[0049] S1 Fully mix 95mL of 30g / L magnesium chloride solution and 5mL of lanthanum cerium chloride solution (wherein the concentration of lanthanum chloride is 20g / L, and the concentration of cerium chloride is 20g / L) under the condition of stirring at a temperature of 50°C Add 200mL of a mixed solution of sodium fluoride and sodium hydroxide at a speed of 20L / min for precipitation (wherein the concentration of sodium fluoride is 5g / L and the concentration of sodium hydroxide is 90g / L), age for 16 hours, and filter to obtain fluoride Magnesium hydroxide composite precipitation;

[0050] S2 Composite precipitation of fluorinated magnesium hydroxide, dried at 110°C, put into a sagger and put into a shuttle-type industrial kiln for roasting according to the following roasting curve. ℃, roasting for 8h;

[0051] The second stage: at 420 ° C, heat p...

Embodiment 3

[0057] A preparation method of lanthanum cerium modified magnesium oxide composite polishing powder, which comprises the steps of:

[0058] S1 Fully mix 38.8mL of 50g / L magnesium chloride solution and 5mL of lanthanum cerium chloride solution (wherein the concentration of lanthanum chloride is 20g / L, and the concentration of cerium chloride is 20g / L) under the condition of stirring at a temperature of 50°C Add the mixed solution of 200mL sodium fluoride and sodium hydroxide with the speed of 12L / min and carry out precipitation (wherein, sodium fluoride concentration is 5g / L, and sodium hydroxide concentration is 90g / L), aging 16 hours, filter, obtain Fluorinated magnesium hydroxide composite precipitation;

[0059] S2 Composite precipitation of fluorinated magnesium hydroxide, dried at 110°C, put into a sagger and put into a shuttle-type industrial kiln for roasting according to the following roasting curve. ℃, roasting for 8h;

[0060] The second stage: at 420 ° C, heat pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com