Magnetic ring sintering process and sintering furnace

A sintering furnace and process technology, applied in the direction of furnace, furnace cooling, charge and other directions, can solve the problems of sintering atmosphere that cannot form a cycle, uneven heating of products, and poor utilization of heat energy, etc., to improve the cooling effect and improve the utilization of heat energy. rate, and the effect of inhibiting high temperature volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

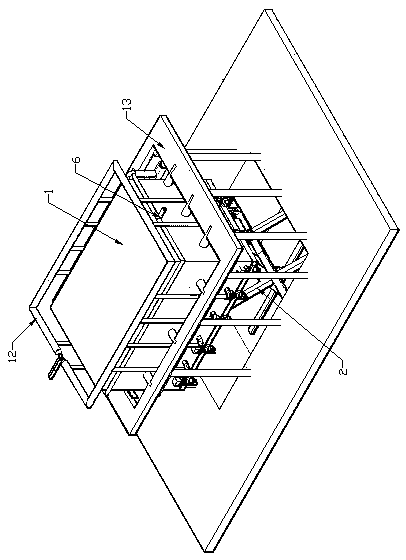

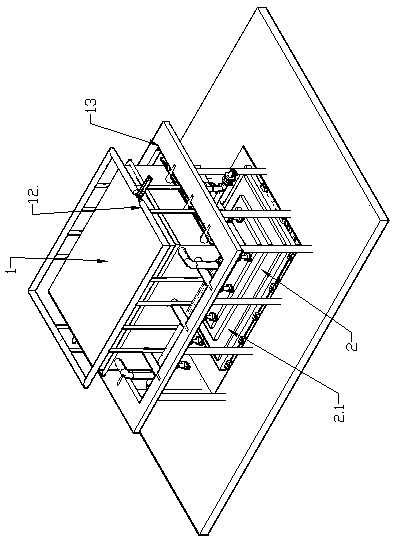

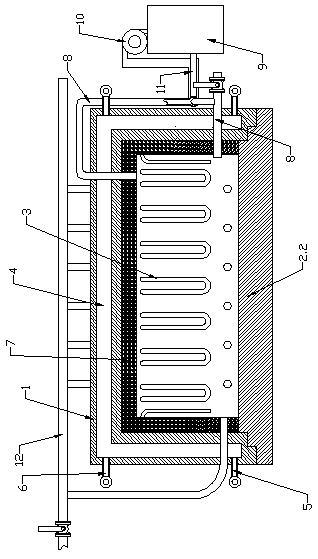

[0029] The magnetic ring sintering process of the present embodiment adopts such as Figure 1-5 The vacuum high-temperature bell jar kiln shown is used as a sintering furnace. First, the temperature in the sintering furnace is raised from room temperature to 1350-1400°C at a rate of 1.8-2.0°C / min. During the heating period, the sintering atmosphere of the sintering furnace is controlled in a conventional manner. , the sintering atmosphere is a nitrogen atmosphere with an oxygen content of 0.5%, and then keep it warm for 6-7h. During the cooling period, the sintering atmosphere of the sintering furnace is also controlled in a conventional manner. The sintering atmosphere is still a nitrogen atmosphere with an oxygen content of 0.5%. Finally, the temperature in the sintering furnace is lowered to 300°C in stages to complete the cooling. The cooling rate is 1.25-1.35°C / min.

Embodiment 2

[0031] The magnetic ring sintering process of the present embodiment adopts such as Figure 1-5 The vacuum high-temperature bell jar kiln shown is used as a sintering furnace. First, the temperature in the sintering furnace is raised from room temperature to 1350-1400°C at a rate of 2.0-2.5°C / min. During the heating period, the sintering atmosphere of the sintering furnace is controlled in a conventional manner. , the sintering atmosphere is a nitrogen atmosphere with an oxygen content of 35%, and then keep it warm for 6-7h. During the cooling period, the sintering atmosphere of the sintering furnace is also controlled in a conventional manner. The sintering atmosphere is still a nitrogen atmosphere with an oxygen content of 35%. Finally, the temperature in the sintering furnace is lowered to 300°C in stages to complete the cooling. The cooling rate is 1.35-1.65°C / min.

Embodiment 3

[0033] The magnetic ring sintering process of the present embodiment adopts such as Figure 1-5 The vacuum high-temperature bell jar kiln shown is used as a sintering furnace. First, the temperature in the sintering furnace is raised from room temperature to 1350-1400°C at a rate of 2.0-2.5°C / min. During the heating period, the sintering atmosphere of the sintering furnace is controlled in a conventional manner. , the sintering atmosphere is a nitrogen atmosphere with an oxygen content of 0.5%, and then keep it warm for 6-7 hours. During the cooling period, the sintering atmosphere of the sintering furnace is also controlled in a conventional manner. The sintering atmosphere is still a nitrogen atmosphere with an oxygen content of 35%. Finally, the temperature in the sintering furnace is lowered to 300°C in stages to complete the cooling. The cooling rate is 1.35-1.65°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com