Preparation method and application of MXene/gold nanoparticle composite electrode material

A technology of gold nanoparticles and composite electrodes, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems that the performance of MXene electrode materials cannot be further improved, and the high conductivity and high specific surface area cannot be achieved simultaneously. Achieve the effect of improving electrochemical performance, good flexibility, and improving capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

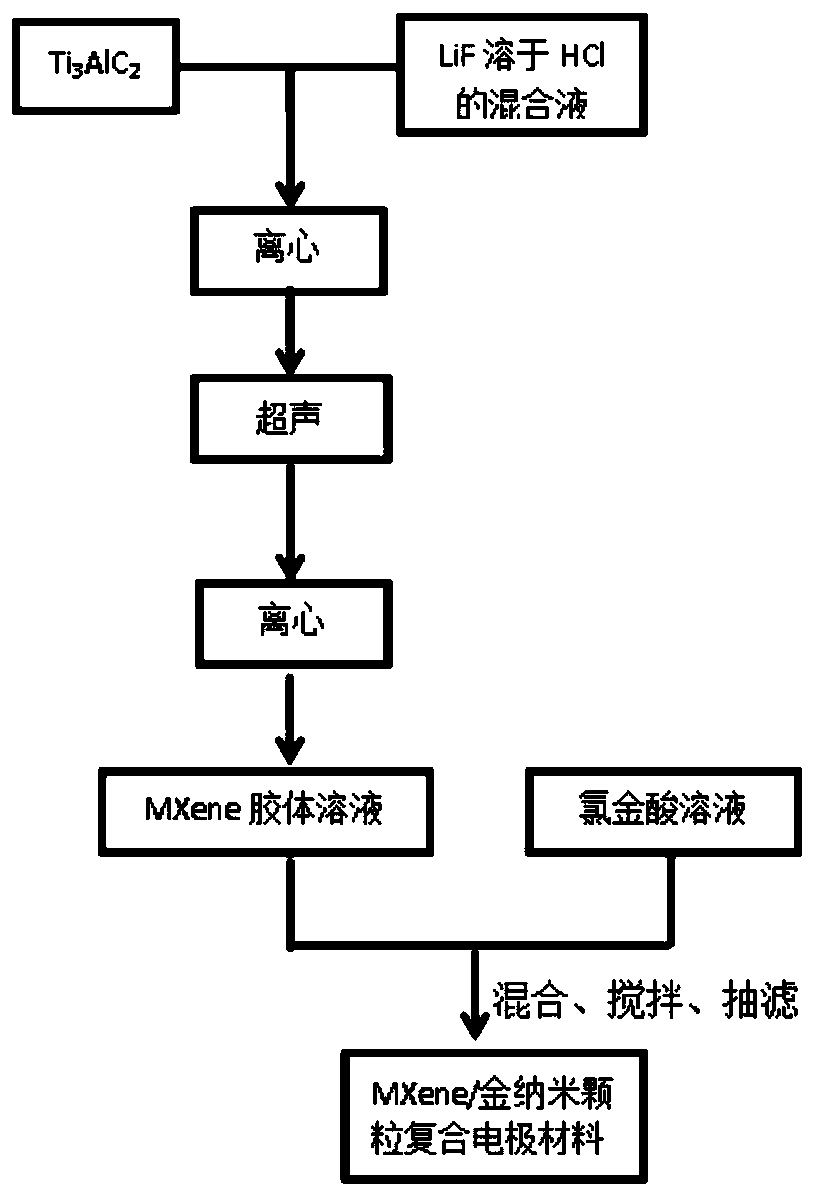

[0034] see figure 1 , a method for preparing a MXene / gold nanoparticle composite electrode material provided by an embodiment of the present invention comprises the following steps:

[0035] Add LiF to 12M hydrochloric acid solution and stir until clarification to prepare corrosion solution;

[0036] Add Ti to the etchant 3 AlC 2 Powder, react with slight heat for 20-28h, then wash and centrifuge until the pH of the supernatant is greater than 6;

[0037] Disperse the precipitate obtained by centrifugation into deionized water for ultrasonic treatment, and then centrifuge the solution after ultrasonic treatment, and the obtained supernatant is the MXene colloidal solution;

[0038] Calculate the concentration of the MXene colloidal solution, add deoxygenated deionized water to obtain a MXene colloidal solution with a concentration of 0.5-2 mg / ml;

[0039] The preparation mass fraction is 1% chloroauric acid aqueous solution, and as required, the chloroauric acid aqueous so...

Embodiment 1

[0046] (1) Add 1g LiF into 20Ml 12M HCl solution, and use magnetic stirring for 20min to dissolve LiF in the HCl solution, and the mixed solution is clear without obvious particles.

[0047] (2) 1gTi 3 AlC 2 The powder is slowly added to the mixed solution in step (1), and the mixed solution is slowly stirred during the addition.

[0048] (3) The solution in step (2) was stirred by magnetic force for 10 min, and placed in a water bath at 35° C. for 24 h, with a rotation speed of 300 rpm.

[0049] (4) The reaction solution obtained in step (3) was centrifuged and washed at 3500 rpm for 3 minutes each time, and after 6-7 times, the pH of the supernatant was greater than 6, and the precipitate of the reactant was obtained.

[0050] (5) Disperse the precipitated reactant obtained in step (4) into 100 ml of deionized water, and blow in Ar gas for 30 min.

[0051] (6) Ultrasonicate the dispersion liquid in step (5) for 1 hour under aeration, and keep the water temperature not exc...

Embodiment 2

[0060] (1) Add 1g LiF into 20Ml 12M HCl solution, and use magnetic stirring for 20min to dissolve LiF in the HCl solution, and the mixed solution is clear without obvious particles.

[0061] (2) 1gTi 3 AlC 2 The powder is slowly added to the mixed solution in step (1), and the mixed solution is slowly stirred during the addition.

[0062] (3) The solution in step (2) was stirred by magnetic force for 10 min, and placed in a water bath at 35° C. for 24 h, with a rotation speed of 300 rpm.

[0063] (4) The reaction solution obtained in step (3) was centrifuged and washed at 3500 rpm for 3 minutes each time, and after 6-7 times, the pH of the supernatant was greater than 6, and the precipitate of the reactant was obtained.

[0064] (5) Disperse the precipitated reactant obtained in step (4) into 100 ml of deionized water, and blow in Ar gas for 30 min.

[0065] (6) Ultrasonicate the dispersion liquid in step (5) for 1 hour under aeration, and keep the water temperature not exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com