Pretreatment method of failure lithium ion battery positive electrode material

A positive electrode material and pretreatment technology, applied to battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as unsatisfactory lithium supplementation effects, achieve improved regeneration efficiency and performance indicators, simple and efficient procedures, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for pretreatment of positive electrode materials of invalid lithium-ion batteries, comprising the following steps:

[0052] S1 Weigh 7.66g of LiOH into a beaker with an electronic balance, add 80ml of distilled water with a pipette, stir magnetically for 20min to dissolve, and prepare a 4mol / L lithium salt solution.

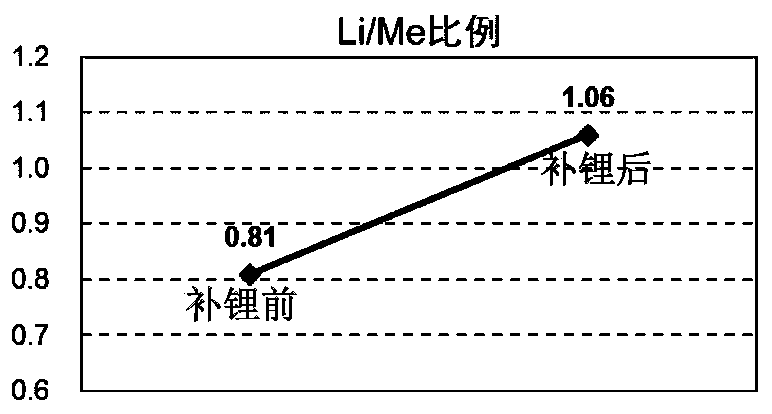

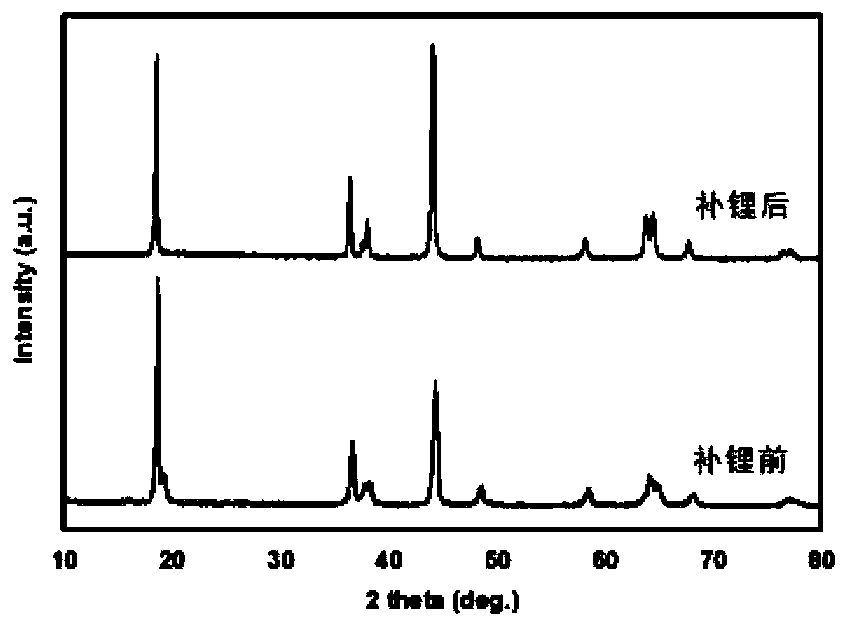

[0053] S2 uses ICP to test the failed cathode material NCM523 (LiNi 0.5 co 0.2 mn 0.3 o 2), the Li / Me ratio in the present embodiment is measured to be 0.81, and the ratio of lithium deficiency is 0.19. Weigh 25.0 g of the failed cathode material, add the lithium salt solution of S1, so that the molar ratio of lithium in the lithium salt solution to the failed cathode material is 3.5, which is 17 times the lithium deficiency ratio x, and stir magnetically for 10 minutes to obtain a mixture.

[0054] S3 Transfer the mixture of S2 to a high-pressure hydrothermal kettle with a PTFE liner, and perform a hydrothermal reaction at a temperature of 20...

Embodiment 2

[0060] A method for pretreatment of positive electrode materials of invalid lithium-ion batteries, comprising the following steps:

[0061] S1 weighs 22.17g of Li with an electronic balance 2 CO 3 In the beaker, add 60ml of distilled water with a pipette, stir magnetically for 10min to dissolve, and configure a 5mol / L lithium salt solution.

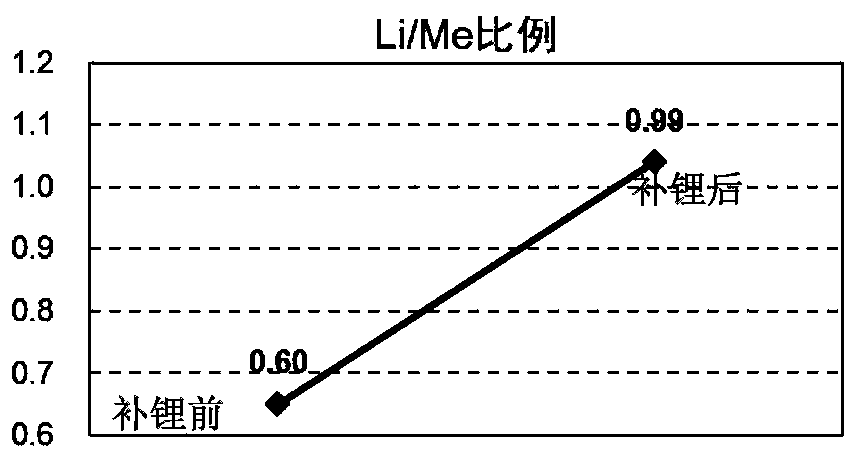

[0062] S2 Testing the failed cathode material LiCoO with ICP 2 The Li / Co ratio in the present embodiment is measured to be 0.60, and the ratio of lithium deficiency is 0.40. Weigh 56g of the failed positive electrode material, add the lithium salt solution of S1, so that the molar ratio of lithium in the lithium salt solution to the failed positive electrode material is 3, which is 7.5 times the lithium deficiency ratio x, and stir magnetically for 10 minutes to obtain a mixture.

[0063] S3 Transfer the mixture of S2 to a high-pressure hydrothermal kettle with a PTFE liner, and perform a hydrothermal reaction at a temperature of 240 °...

Embodiment 3

[0068] A method for pretreatment of positive electrode materials of invalid lithium-ion batteries, comprising the following steps:

[0069] S1 Use an electronic balance to weigh 0.72g of LiOH into a beaker, add 30ml of distilled water with a pipette, and stir for 10 minutes to dissolve, and prepare a 1mol / L lithium salt solution;

[0070] S2 Using ICP to test the failed cathode material LiFePO 4 The ratio of Li / Fe in this embodiment is measured to be 0.65, and the ratio of lithium deficiency is 0.35. Weigh 2.37g of the failed positive electrode material, add the lithium salt solution of S1, so that the molar ratio of lithium in the lithium salt solution to the failed positive electrode material is 2, which is 5.7 times the lithium deficiency ratio x, and stir magnetically for 10 minutes to obtain a mixture.

[0071] S3 Transfer the mixture of S2 to a high-pressure hydrothermal kettle with PTFE lining, and perform a hydrothermal reaction at a temperature of 180°C. During the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com