Force-induced responsive polymer based on reversible free radical type force-sensitive group

A technology of free radicals and polymers, applied in the field of force-responsive polymers based on reversible free-radical force-sensitive groups, can solve the problem of poor processing performance and use stability, activation of force-sensitive groups, and no use value, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

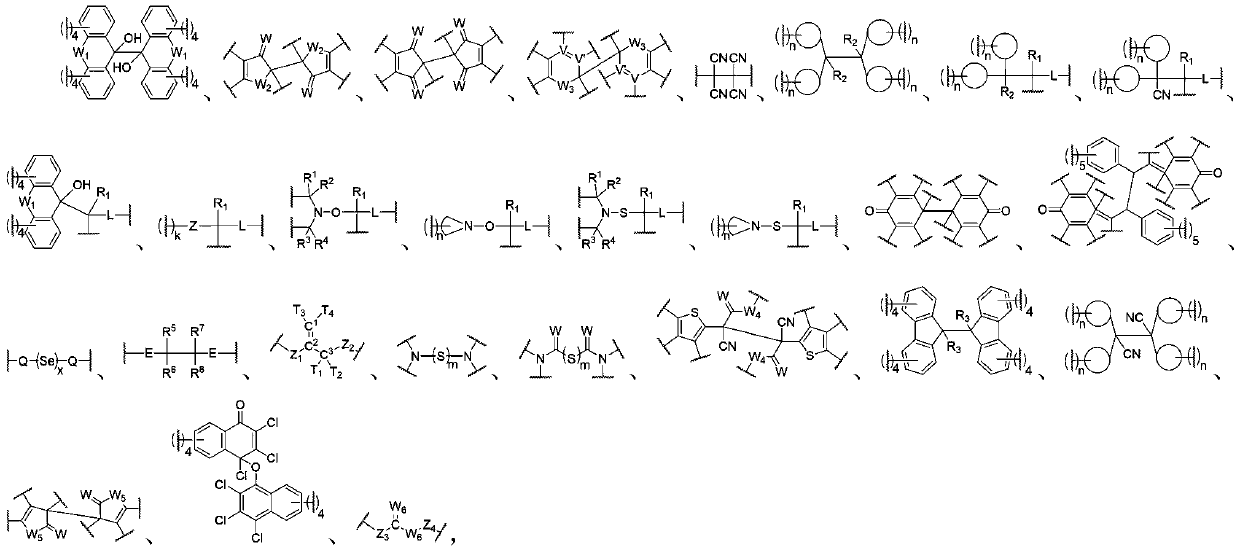

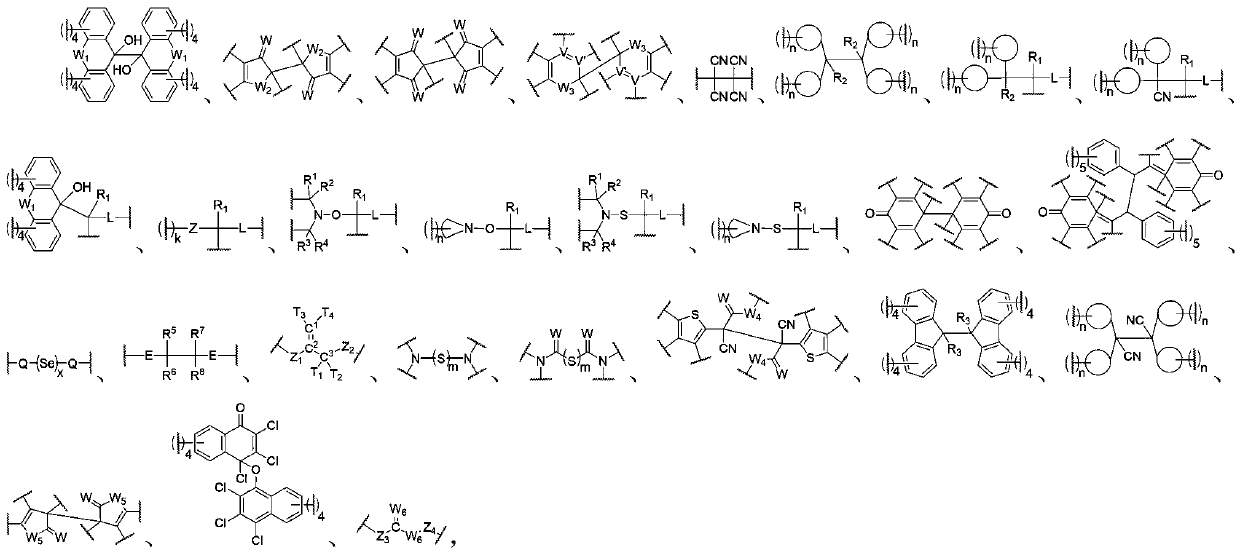

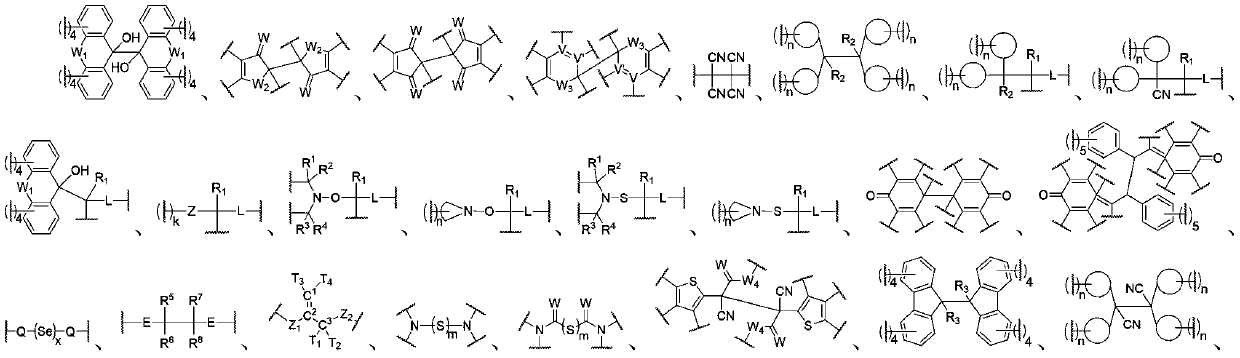

Method used

Image

Examples

preparation example Construction

[0305] In the preparation process of the polymer, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam it.

[0306] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the polymer to make it a uniform foam, and then through physical or Chemical changes shape it into foam. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0307] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the polymer, which includes but is not limited to the following methods: (1) inert gas foaming method, that is, under pressure Under normal circumstances, the inert gas is pressed into the molten polymer or pasty material, and then the pressure is reduced and the te...

Embodiment 1

[0320]

[0321] Using triethylamine as a catalyst, hydrogenated carboxyl-terminated polybutadiene is prepared by reacting hydrogenated hydroxyl-terminated polybutadiene with excess succinic anhydride. Take 5 molar equivalents of compound (a), 10 molar equivalents of hydrogenated carboxy-terminated polybutadiene, put them in a reaction vessel, dissolve them with an appropriate amount of tetrahydrofuran, then add 30 molar equivalents of dicyclohexylcarbodiimide, 5 molar equivalents of 4- Dimethylaminopyridine was stirred and reacted at room temperature for 48 hours. After the reaction was completed, the reactant was poured into a mold and dried naturally to obtain a polymer film at last. The thin film material has the characteristics of oil resistance, water resistance, bending resistance, etc., after rubbing it, it can emit light yellow fluorescence under 380nm ultraviolet light. The polymer film material in this embodiment can be used as an anti-counterfeiting coating mater...

Embodiment 2

[0323]

[0324] Take 5 molar equivalents of hydroxyl-terminated four-armed polyethylene glycol (molecular weight is 4000), 12 moles of single-quantity pinacol derivatives (a), put them in a reaction vessel, dissolve them with an appropriate amount of tetrahydrofuran, and then add 36 molar equivalents of bicyclic Hexylcarbodiimide, 6 molar equivalents of 4-dimethylaminopyridine, then stirred and reacted at room temperature for 24 hours, then added 4 molar equivalents of n-butanol, continued the reaction for 12 hours, then added 3 parts of liquid metal gallium, 0.5 parts of nano-silver to disperse liquid, 0.1 part of sodium dodecylsulfonate, and 150 parts of distilled water, after mixing evenly, pour the mixture into a mold, and place it in a vacuum oven at 50°C for 6 hours. After the tetrahydrofuran is completely volatilized, a polymer object hydrogel. The gel sample will turn yellow-green under stretching, because the mesensitized group in it is activated by force to genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com