Gel type annulus protection liquid and preparation method thereof

An annulus protection liquid and gel-type technology, applied in chemical instruments and methods, earthwork drilling and production, special treatment targets, etc., can solve the problems of freshwater layer pollution, long-term safety and environmental protection restrictions on oil fields, and large hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a preparation method of a gel-type annular space protection solution as follows: (Taking Qingshui Well as an example):

[0036] (1) According to the requirements of well conditions on site, according to the weight ratio of the above-mentioned clear water well protection fluid, first add 0.5 to 1 part of oxygen scavenger to the liquid mixing tank, and then add 1 to 5 parts of corrosion inhibitor and 1 to 3 parts of corrosion inhibitor in the state of constant stirring. 1 part of scale inhibitor, 0.5-3 parts of bactericide, 1-5 parts of salt-resistant polymer, 0.5-2.5 parts of cross-linking agent, and the balance is water. Stir continuously for 30-45 minutes to form a gel-type annular space protection solution .

[0037] (2) The annulus protection fluid prepared in step (1) is circulated into the annulus through the tubing and casing. Under the temperature and pressure of the wellbore, the corrosion inhibitor in the protection fluid is adsor...

Embodiment 1

[0040] Embodiment 1 (indoor test of L1-pull clear water well)

[0041] This embodiment provides a gel-type annulus protection solution for injecting clear water wells, the composition of which is as follows: 3 parts of corrosion inhibitor, 1 part of scale inhibitor, 2 parts of fungicide, and oxygen scavenger : 0.7 parts, hydrophobic association and polymer: 3 parts, 1.5 parts of crosslinking agent, and the rest of water.

[0042] Indoor liquid preparation method: first add 0.7 parts of oxygen scavenger in a large beaker, and then add 3 parts of corrosion inhibitor, 1 part of scale inhibitor, 2 parts of bactericide, 3 parts of hydrophobe and polymer in sequence under constant stirring, 1.5 parts of the joint agent, the balance is water, and stir evenly for 45 minutes to form a gel-type annular space protection solution.

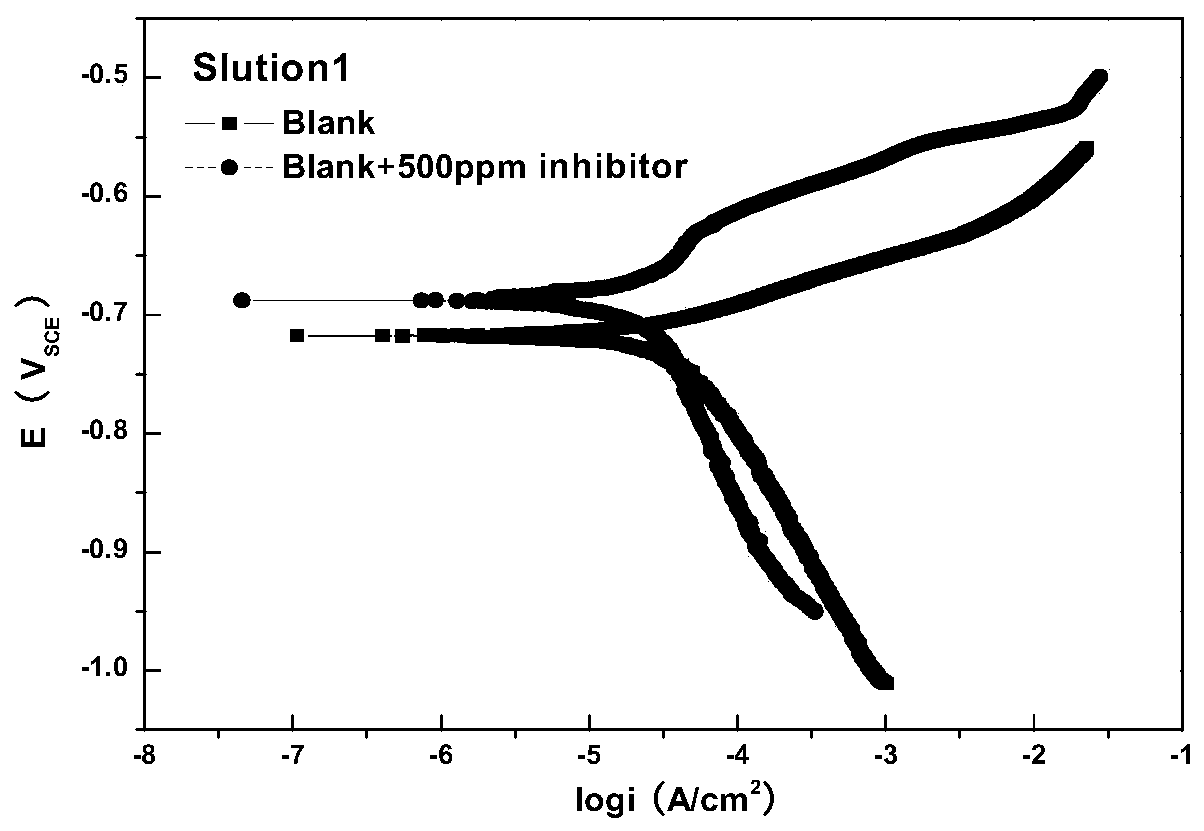

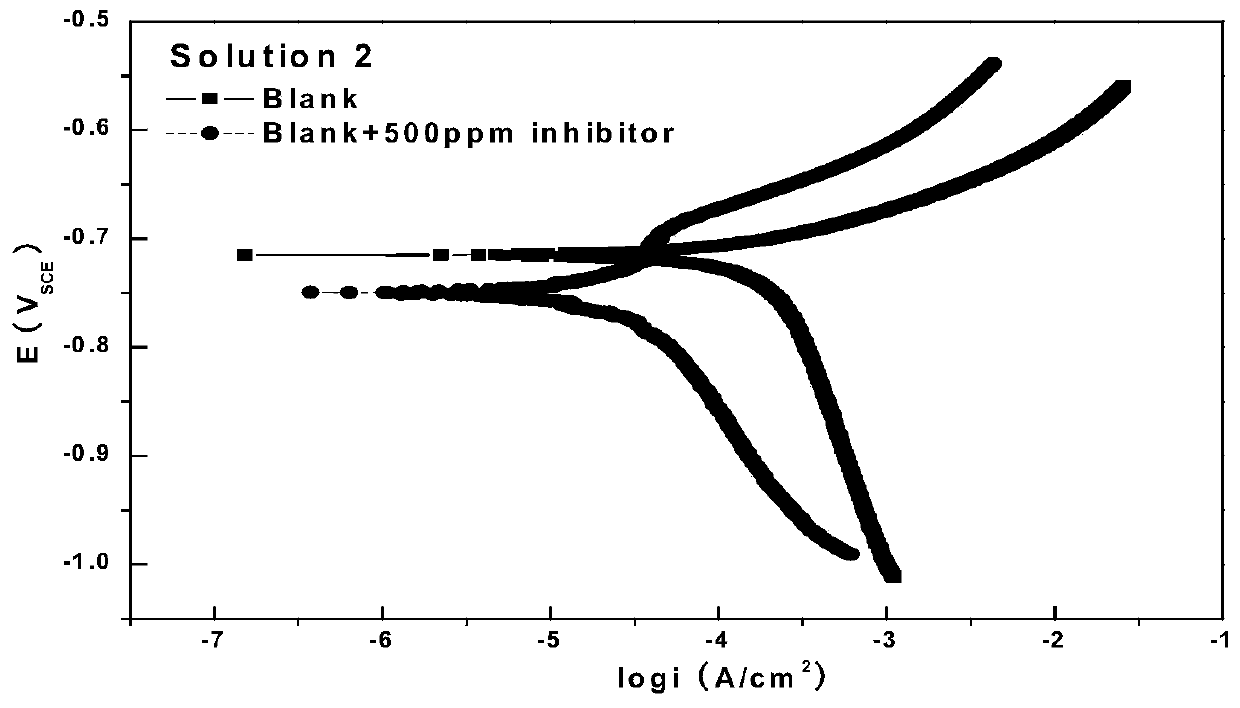

[0043] The indoor electrochemical evaluation experiment shows that the corrosion rate of the blank L1-la clear water is 0.722mm / a, and the corrosion rate aft...

Embodiment 2

[0054] Embodiment 2 (L1- pull clear water well field test)

[0055] This embodiment provides a gel-type annulus protection solution for injecting clear water wells, the composition of which is as follows: 3 parts of corrosion inhibitor, 1 part of scale inhibitor, 2 parts of fungicide, and oxygen scavenger : 0.7 parts, hydrophobic association and polymer: 3 parts, 1.5 parts of crosslinking agent, and the rest of water. (The components of the ring protection solution are shown in Table 1).

[0056] On-site liquid preparation method: first add 0.7 parts of oxygen scavenger to the 10L liquid preparation tank, then add 3 parts of corrosion inhibitor, 1 part of scale inhibitor, 2 parts of bactericide, 3 parts of hydrophobic olefin and polymer in sequence under constant stirring, 1.5 parts of cross-linking agent, the balance is water, and stir evenly for 30 minutes to form a gel-type annular space protection solution.

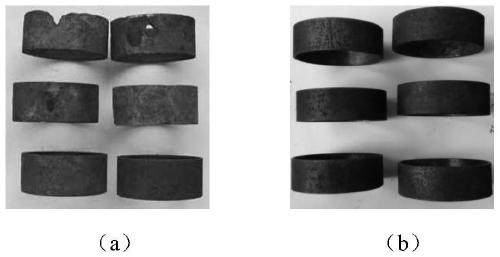

[0057] In August 2018, the annular protection fluid test was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion inhibition rate | aaaaa | aaaaa |

| Corrosion inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com