BIM-based glass fiber composite air duct product production management system

A technology of production management system and composite air duct, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., and can solve problems such as prone to errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

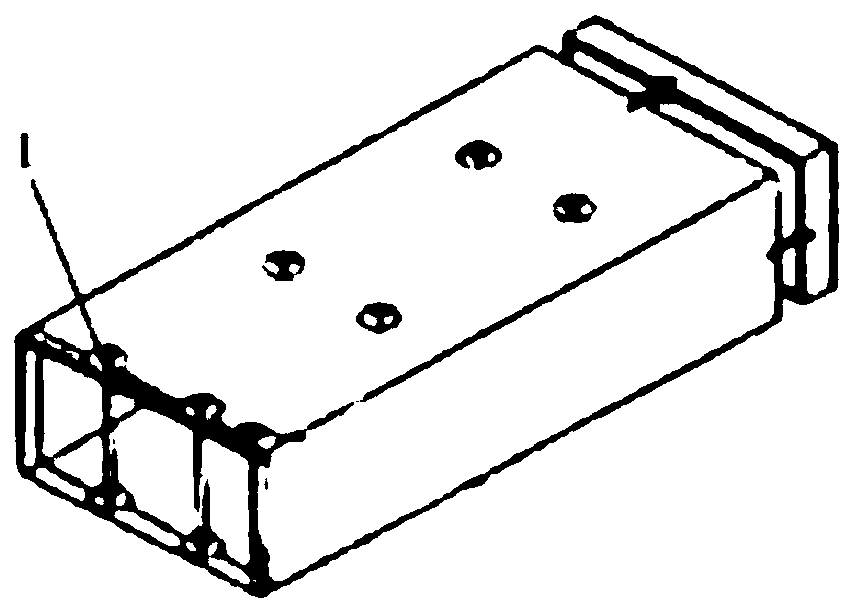

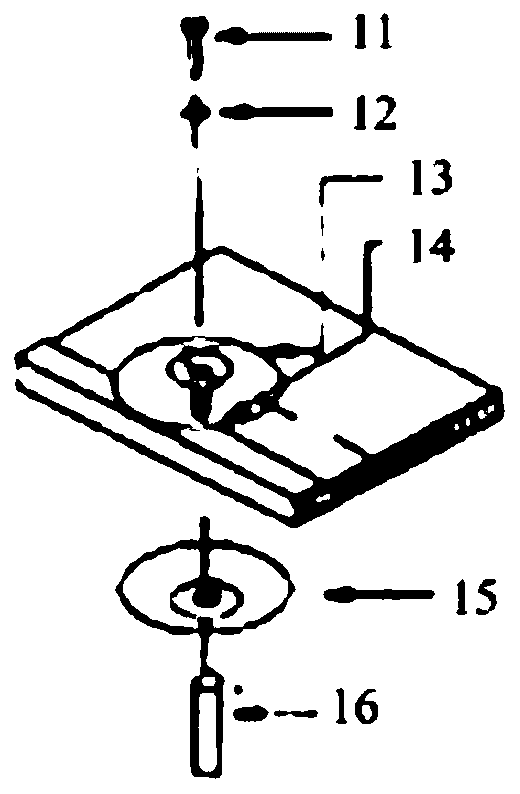

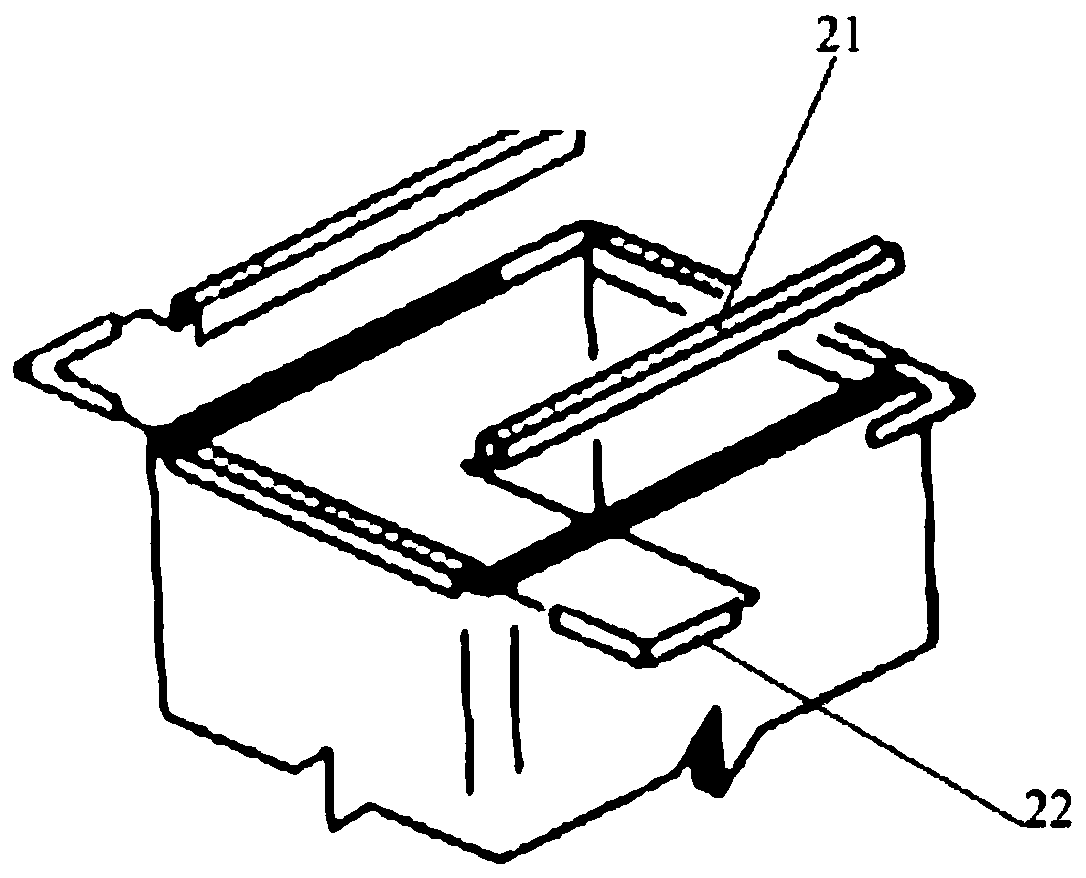

[0075] Glass fiber composite air ducts are mostly used in industrial plants, civil buildings, and commercial buildings, and are suitable for air-conditioning systems below medium pressure; the materials of glass fiber composite air ducts are all Class A non-combustible materials, which are flame retardant and have thermal insulation properties. Good, the thermal conductivity of the air duct board is only 0.030W / mK, and the density is 64 kg / m3; the sound-absorbing performance is better, and the glass fiber composite air duct can eliminate aerodynamic noise. The BIM-based production management method of glass fiber composite air duct products, the specific preparation method is as follows:

[0076] Step 1 Build a primary BIM model through Autodesk Revit according to the requirements of glass fiber composite duct preparation;

[0077] Step 2 Check and adjust the primary BIM model and confirm the secondary BIM model;

[0078] Step 3 Prepare prefabricated products, make secondary adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com