Pressure-resistant positive electrode active material and electrochemical energy storage device

A positive electrode active material and positive electrode material technology, applied in the field of positive electrode active materials and electrochemical energy storage devices, can solve the problems of battery cell cycle performance deterioration, strong surface activity, side reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

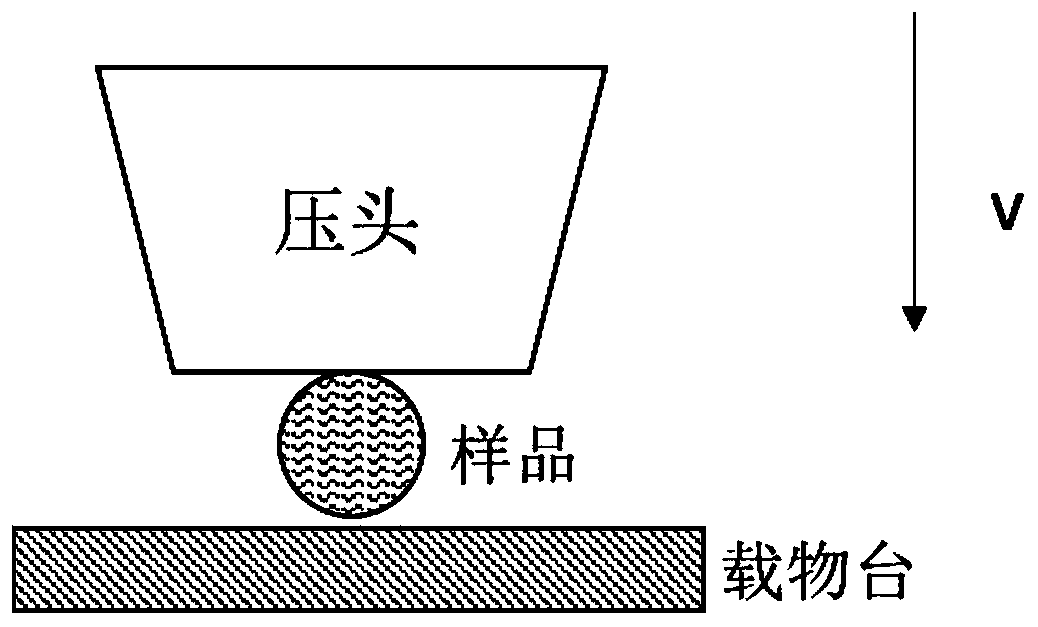

Image

Examples

preparation example Construction

[0062] The fourth aspect of the present invention provides the preparation method of the positive electrode active material of the first aspect of the present invention, the method of the positive electrode active material should be known to those skilled in the art, for example, may include: those skilled in the art may According to the elemental composition of the positive electrode active material, an appropriate raw material and proportion of the positive electrode active material are selected. For example, the raw material of the positive electrode active material may include a ternary material precursor of nickel, cobalt, manganese and / or aluminum, lithium source, Me source, A source, etc., and the ratio between each raw material is generally referred to the ratio of each element in the positive electrode active material. The ratio is matched. More specifically, the ternary material precursor may include but not limited to Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 、Ni 0.5 co 0.2...

Embodiment 1

[0079] 1. Preparation of cathode materials

[0080] 1) Prepare nickel sulfate, manganese sulfate, and cobalt sulfate in a molar ratio of 8:1:1 into a solution with a concentration of 1mol / L, and use hydroxide co-precipitation technology to prepare the nickel-cobalt-manganese ternary material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 . In the process of preparing the precursor, the initial pH value during co-precipitation is controlled to be 9.5, the ammonia concentration is 0.4M, and the post-reaction aging time is 5 h.

[0081] 2) The above-mentioned nickel-cobalt-manganese ternary material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 , Li-containing compound LiOH·H 2 O is placed in a mixing device at a molar ratio of 1:1.05 for mixing, then placed in an atmosphere furnace for sintering at 800 ° C, and after cooling, it is mechanically ground to form the positive active material matrix; the above positive active material matrix and additive Al 2 o 3 According to the mass ratio...

Embodiment 2

[0095] It is basically the same as Example 1, the difference lies in the preparation method of the positive electrode material: during the preparation of the precursor, the pH value of the co-precipitation is adjusted to 10.5, the ammonia concentration is 0.3M, and the aging time after the reaction is 3h.

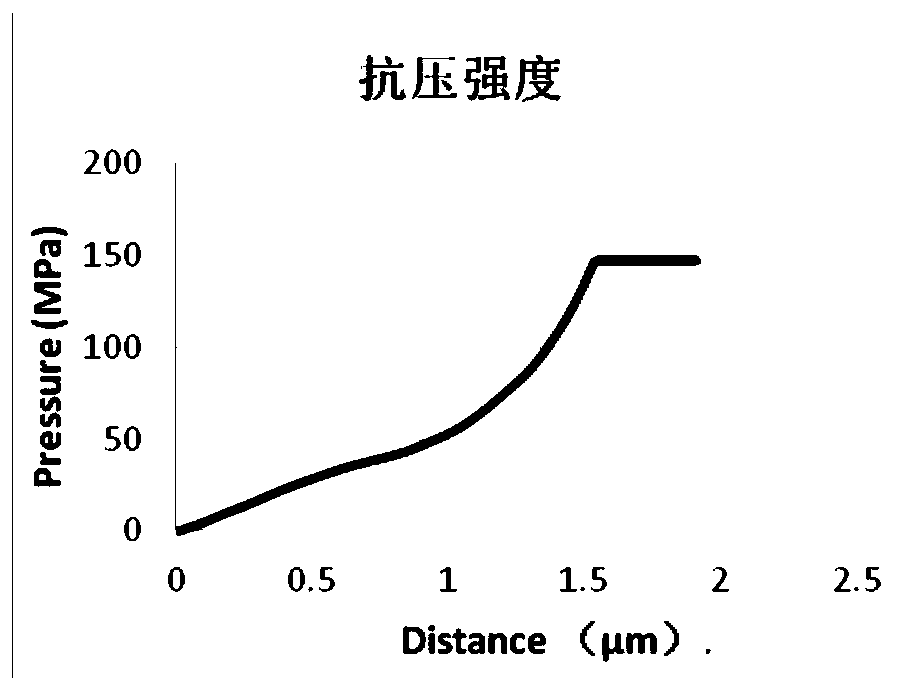

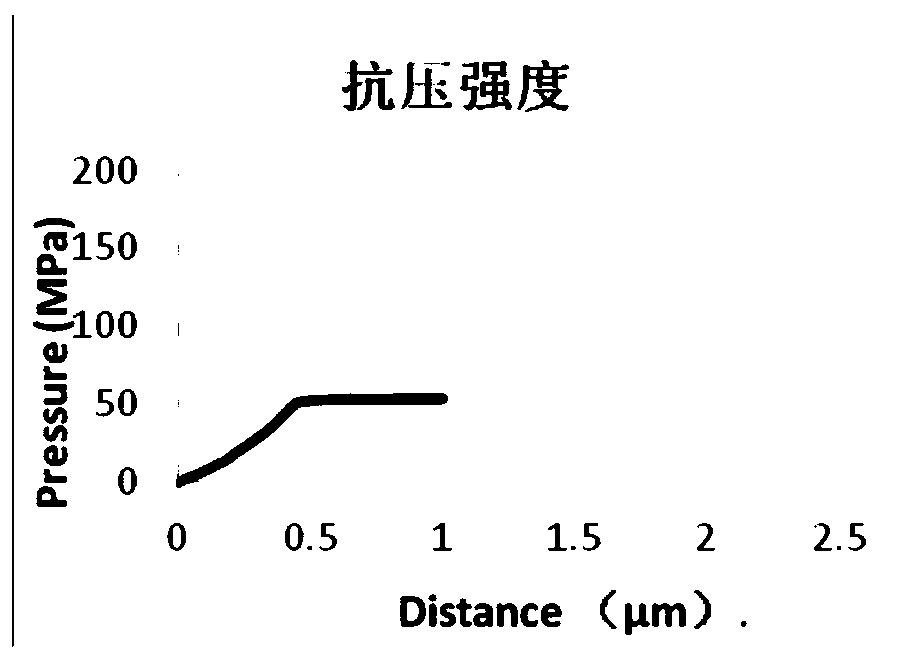

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com