Ship power system with characteristics of clean emission

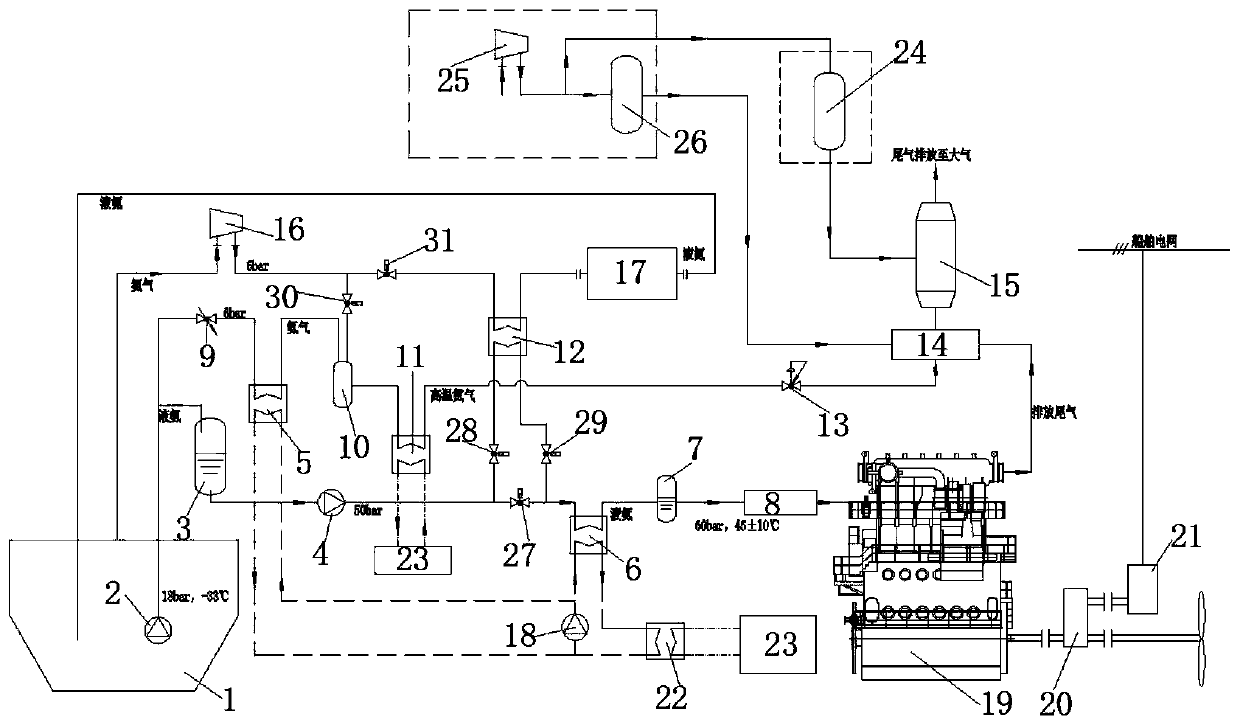

A technology for power systems and ships, applied in ship propulsion, ship construction, exhaust devices, etc., can solve problems such as liquid ammonia volatilization, storage tank pressure rise, safety valve take-off accidents, etc., to achieve uniform diffusion, reduced volume, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] When the ship is in operation, the ammonia volatilized gas in the liquid ammonia fuel storage tank is less than or basically equal to the demand for ammonia gas during tail gas treatment, open the first valve and the fourth valve, close the second valve, the third valve and the liquid ammonia vaporization Inside the device. When the amount of volatile gas in the liquid ammonia fuel storage tank is too much, and the ammonia fuel engine tail gas treatment requires a small amount of ammonia, this situation may occur when the volume of the liquid ammonia fuel storage tank is too large, the liquid ammonia fuel storage tank has poor cooling effect, and the ship The operating environment is bad or the host is in the Tire II operating mode without exhaust gas denitrification treatment.

[0045] Through the ammonia fuel supply system, the low-temperature liquid ammonia sequentially passes through the liquid ammonia daily tank and the liquid ammonia booster pump. After the delivery ...

Embodiment 2

[0050] When there is too much volatile gas in the liquid ammonia fuel storage tank, which exceeds the amount required for exhaust gas treatment, open the second valve, the third valve, and the fifth valve, close the first and fourth valves, and open the fifth valve to start ammonia liquefaction system. This situation may occur when the volume of the liquid ammonia fuel storage tank is too large, the cooling effect of the liquid ammonia fuel storage tank is poor, the operating environment of the ship is bad, or the main engine is in the Tire II operating mode without exhaust gas denitrification treatment. The volatilized ammonia gas in the liquid ammonia fuel storage tank passes through the ammonia compressor and enters the ammonia pre-cooler through the fifth valve. The heat exchange is performed at the ammonia pre-cooler, and the ammonia gas is pre-cooled, and the cooled ammonia enters The ammonia liquefaction device, after liquefaction, forms liquid ammonia, which returns to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com