Energy-saving low-carbon soft porcelain decorative material and preparation method thereof

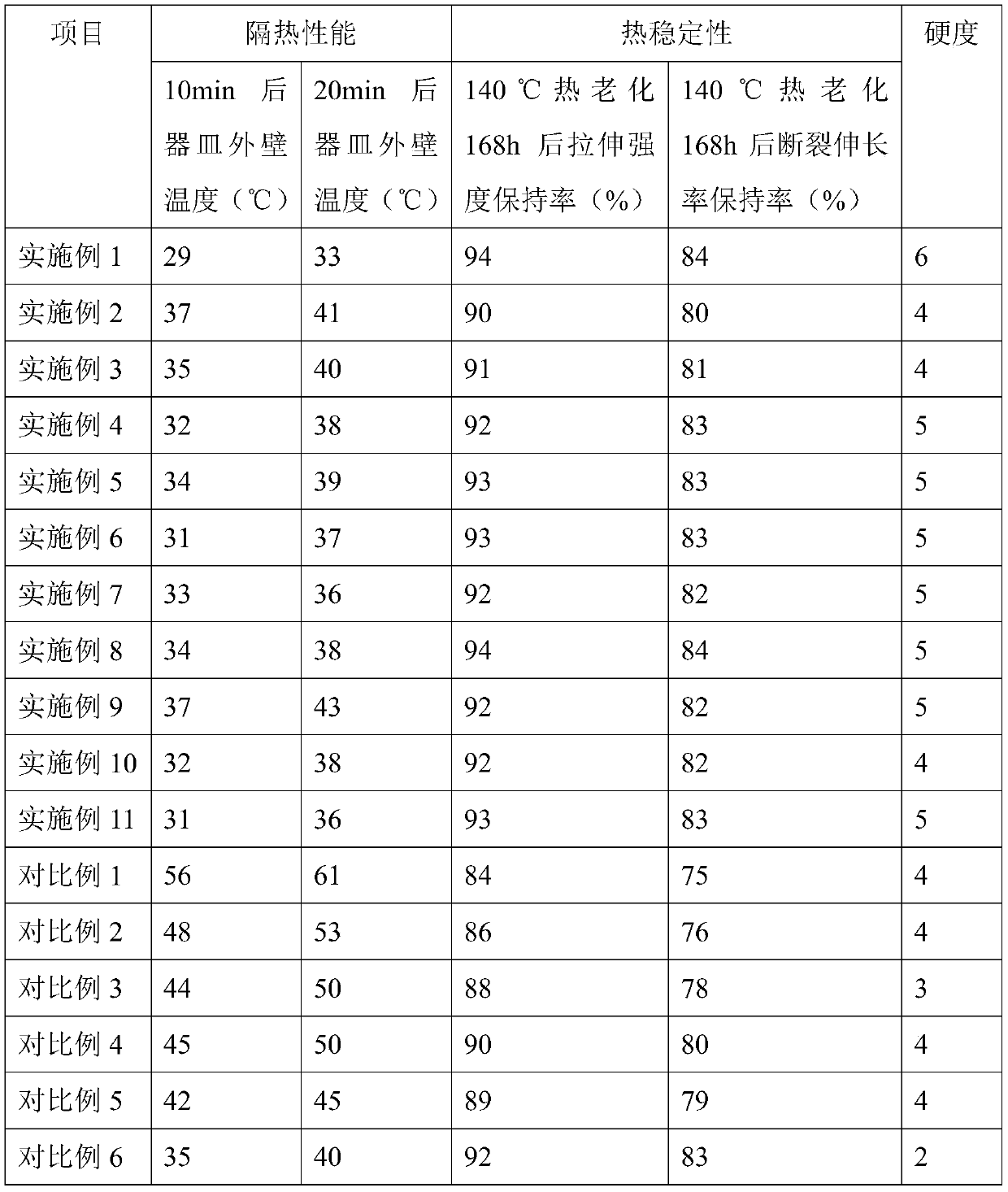

A decorative material, a technology of soft porcelain, applied in the field of architectural decoration, can solve the problems of low hardness, poor thermal stability, poor thermal insulation performance, etc., and achieve high temperature resistance, improved waterproof performance, and enhanced strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation example of silver-coated hollow glass microspheres

[0036] The preparation method of silver-plated hollow glass microspheres comprises the following steps:

[0037] Cleaning: Clean the surface of the hollow glass microspheres, and wash off the oil stains on the surface of the hollow glass microspheres with hot lye;

[0038] Coarsening: Immerse the cleaned hollow glass microspheres in hydrofluoric acid (mass concentration: 10%) to erode the surface of the hollow glass microspheres to form more micropores or grooves, and enhance the ability to adsorb ions on the surface of the microspheres. Enhance the bonding force between hollow glass microspheres and silver;

[0039] Pretreatment: immerse hollow glass microspheres in SnCl 2 acid solution (mass concentration is 5% SnCl 2 +1%HCl) to sensitize to form an active surface, make the surface of the glass beads adsorb a layer of colloidal film containing stannous ions, and then immerse the sensitized hollow glas...

preparation example 1

[0042] The preparation method of silver-plated hollow glass microspheres comprises the following steps:

[0043] Cleaning: Clean the surface of the hollow glass microspheres, and wash off the oil stains on the surface of the hollow glass microspheres with hot lye;

[0044] Coarsening: Immerse the cleaned hollow glass microspheres in hydrofluoric acid with a mass concentration of 10%, to erode the surface of the hollow glass microspheres to form more micropores or grooves, enhance the ability of adsorbing ions on the surface of the microbeads, and enhance The binding force between hollow glass microspheres and silver;

[0045] Pretreatment: immerse hollow glass microspheres with a mass concentration of 5% SnCl 2 Sensitized with 1% HCl in a mixed acid solution to form an active surface, SnCl 2 The mass of HCl and HCl is 5:1, so that the surface of the glass beads is adsorbed with a colloidal film containing stannous ions, and then the sensitized hollow glass beads are immersed...

preparation example 2

[0048] The preparation method of silver-plated hollow glass microspheres is carried out according to the method in Preparation Example 1, the difference is: in the silver-plating step: the pretreated hollow glass microspheres with a mass ratio of 1:5 are mixed with water to obtain a suspension , then add reducing agent, stabilizer and surfactant successively, and then add dropwise silver nitrate and complexing agent, obtain silver-plated hollow glass microspheres, complexing agent selects triethanolamine for use, stabilizer selects sodium carboxymethylcellulose for use, The surfactant is polyethylene glycol, the reducing agent is sodium borohydride, the mass ratio of hollow glass microspheres to the sum of silver nitrate, complexing agent, stabilizer, surfactant and reducing agent is 1:0.3, and the silver nitrate and reducing agent The mass ratio of agent, stabilizer and surfactant is 1:0.8:0.3:0.1, and the mass ratio of silver nitrate to complexing agent is 1:0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com