A method for preparing silicon-magnesium gel from asbestos tailings magnetic separation iron powder and residue

A technology of asbestos tailings and silicon-magnesium gel, which is applied in chemical instruments and methods, gel preparation, silicon oxide, etc., achieves the effects of high economy, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

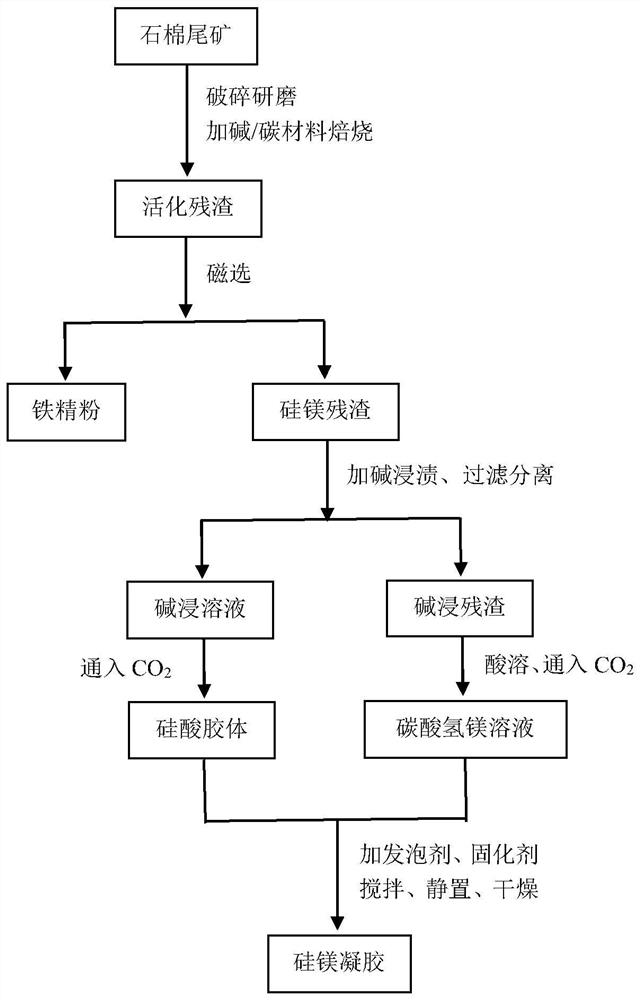

[0036] A kind of asbestos tailings magnetic separation iron fine powder and residue of the present embodiment prepare the method for silicon-magnesium gel, and its process flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0037] (1) Crushing and grinding the asbestos tailings to pass through a 150-mesh sieve, mixing and grinding with 0.5 times the weight of sodium hydroxide and 0.5 times the weight of lignite, and then roasting and activating to obtain an activated residue. The roasting temperature is 800 ° C and the roasting time is 2 hours;

[0038] (2) The activation residue is magnetically separated by a magnetic separator with a field strength of 12000Oe to obtain iron concentrate powder and silicon-magnesium residue with a grade of 68% and a yield of 90.5%;

[0039] (3) Si-Mg residue is impregnated with a sodium hydroxide solution of concentration 1.0mol / L, and separated by filtration to obtain alkali leaching solution and alkali leaching r...

Embodiment 2

[0043] A kind of asbestos tailings magnetic separation iron fine powder and residue of the present embodiment prepare the method for silicon-magnesium gel, and its process flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0044] (1) Crushing and grinding the asbestos tailings to pass through a 200-mesh sieve, mixing and grinding with 1.0 times the weight of sodium hydroxide and 0.5 times the weight of lignite, and then roasting and activating to obtain an activated residue. The roasting temperature is 800 ° C and the roasting time is 2 hours;

[0045](2) The activation residue adopts the magnetic separator of field strength 20000Oe to carry out magnetic separation, obtains the iron fine powder of grade 64%, productive rate 86% and silicon-magnesium residue;

[0046] (3) Si-Mg residue is impregnated with a sodium hydroxide solution of concentration 1.0mol / L, and separated by filtration to obtain alkali leaching solution and alkali leaching residue...

Embodiment 3

[0050] A kind of asbestos tailings magnetic separation iron fine powder and residue of the present embodiment prepare the method for silicon-magnesium gel, and its process flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0051] (1) Crushing and grinding the asbestos tailings to pass through a 200-mesh sieve, mixing and grinding with 1.0 times the weight of sodium hydroxide and 1 times the weight of coke, and then roasting and activating to obtain an activated residue, the roasting temperature is 800 ° C, and the roasting time is 2 hours;

[0052] (2) The activation residue adopts the magnetic separator of field strength 20000Oe to carry out magnetic separation, obtains the iron fine powder of grade 62%, productive rate 92.6% and silicon-magnesium residue;

[0053] (3) Si-Mg residue is impregnated with a sodium hydroxide solution of concentration 1.0mol / L, and separated by filtration to obtain alkali leaching solution and alkali leaching residue;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com