Zearalenone hydrolytic enzyme and coding gene and application thereof

A technology of zearalenone and coding genes, applied in the field of feed enzymes, can solve problems such as loss of nutrients, residual chemical reagents, and ineffective degradation of toxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Construction of recombinant erythralenone hydrolase ZENWJ expression vector

[0035] The optimized gene sequence was directly connected to the expression vector pHT43 and the zearalenone hydrolase coding gene zenwj by Gene Synthesis Company to obtain the recombinant plasmid pHT43-zenwj and transform it into Bacillus subtilis WB800N to obtain the recombinant Bacillus subtilis strain WB800N / zenwj.

[0036] After the sequencing was correct, the recombinant plasmid pHT43-zenwj was transformed into Bacillus subtilis competent WB800N for induced expression. Pick 3-5 positive transformants and inoculate them into 30ml 2xYT liquid medium containing 100μg / ml kanamycin, culture at 37°C and 250rpm for 6 hours, this is pre-culture; transfer this pre-culture to 300ml containing In 2xYT liquid medium with 100 μg / ml kanamycin, culture at 37°C and 250 rpm for 2-3 hours, the OD600 is about 0.5. 1M IPTG stock solution was added to the culture to make the final concentration...

Embodiment 2

[0037] Example 2 Activity detection and analysis of recombinant erythralenone hydrolase

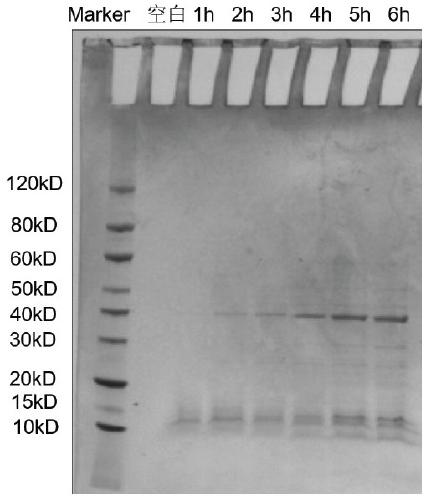

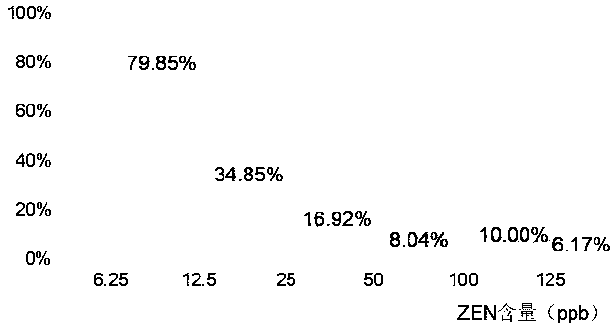

[0038] ZENWJ of codon-optimized erythralenone hydrolase, induced by IPTG, expressed and purified, the protein SDS-PAGE analysis results are as follows figure 1 As shown, the analysis of the degradation of different concentrations of zearalenone by zearalenone hydrolase is as follows figure 2 as shown,

[0039] The reaction system is:

[0040] 800ul of disodium hydrogen phosphate citrate buffer solution with pH6.0, plus 100ul of 0.5g / L zearalenone toxin (purchased from sigma company) dissolved in DMSO, and then add 100ul of enzyme solution properly diluted, 37 Incubate at 100°C for one hour, then add 2 times the volume of DMSO to terminate the reaction, and shake vigorously at the same time, draw part of the sample through a microporous membrane, and load it for high-performance liquid phase analysis (HPLC). The control is an appropriately diluted enzyme solution in a boiling water bath...

Embodiment 3

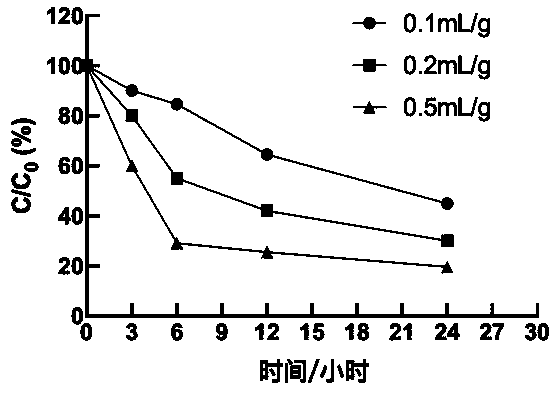

[0042] Example 3 Application experiment of zearalenone hydrolase ZENWJ

[0043]Corn dregs contaminated with ZEN were collected from the market, and the ZEN content was detected to be 1225 μg / kg. The Bacillus subtilis fermentation supernatant (enzyme liquid) was diluted 2, 5, and 10 times with buffer solution. According to the 1:1 ratio of fermentation liquid and corn dregs (v:w), mix evenly (that is, the enzyme liquid addition amount is 0.1, 0.2, 0.5mL / g), and react at 37°C for 0, 3, 6, 12, 24h, without Enzyme solution was added as a control. ZEN in corn dregs was extracted according to GB / T 23504-2009, the residual amount of ZEN was detected by HPLC, and the degradation rate of ZEN in corn dregs was calculated.

[0044] Such as image 3 As shown, with the extension of the degradation time, the ZEN content in the sample gradually decreased, the degradation rate was faster in the first 6 hours of the reaction, and the degradation rate tended to be gentle after 6 hours. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com