Room-temperature blocky multiferroic single crystal and preparation method thereof

A room temperature and bulk technology is applied in the field of room temperature bulk multiferroic single crystal ScxGa2-x-yFeyO3 and its preparation, and can solve the problems of inability to obtain a homogeneous bulk single crystal, changes in crystal structure, changes in composition distribution, etc. To achieve the effect of easy control, prevention of segregation and uniform doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

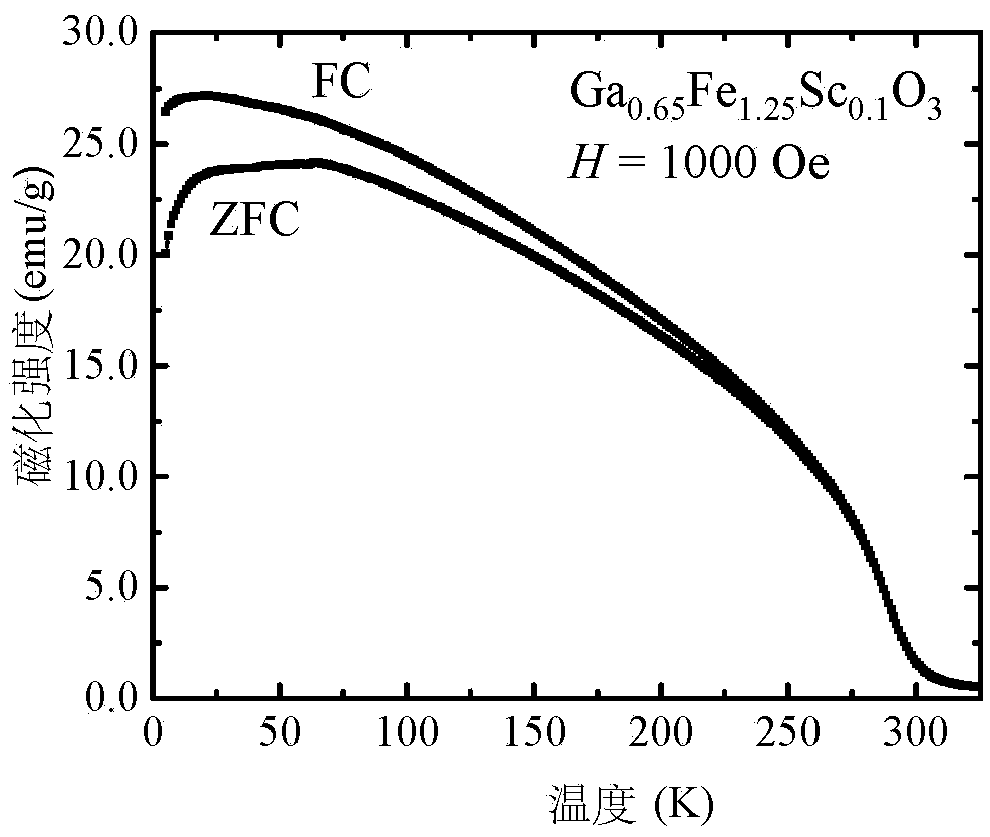

[0055] (1) Ingredients: Sc with a purity of not less than 99.99% 2 o 3 , Fe 2 o 3 and Ga 2 o 3 The powder is prepared according to the stoichiometric ratio of Sc x Ga 2-x-y Fe y o 3 where x=0.1, y=1.25;

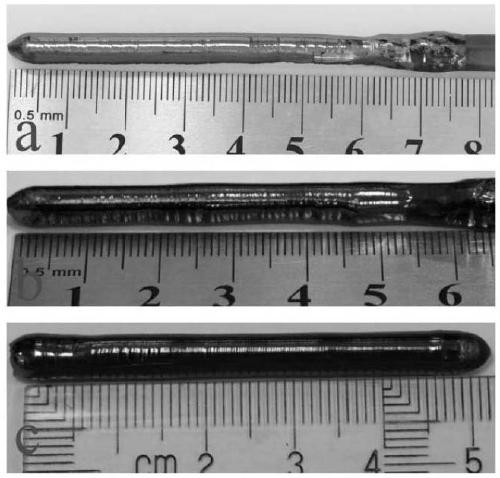

[0056] (2) Preparation of material rod: ball mill the mixture prepared in step (1) for 24 hours, dry at 100°C for 2 hours, pre-fire at 1200°C for 15 hours, and then grind again, then put the ground powder into a long strip Sealed in a balloon, made into a rod shape under an isostatic pressure of 60-70 MPa, and then removed the balloon to obtain a rod;

[0057] (3) Sintering: Sinter the material rod obtained in step (2) at 1350° C. for 15 hours in a high-temperature furnace to obtain a dense polycrystalline rod, which is used for crystal growth;

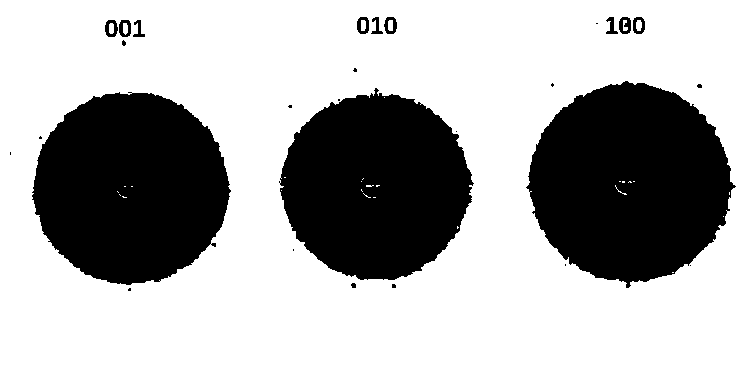

[0058] (4) Crystal growth: the polycrystalline rod in step (3) is used as the feeding rod and the feeding rod, and the feeding rod is hung on the upper end of the light floating zone furnace with a platinum wire, and the fe...

Embodiment 2

[0060] (1) Ingredients: Sc with a purity of not less than 99.99% 2 o 3 , Fe 2 o 3 and Ga 2 o 3 The powder is prepared according to the stoichiometric ratio of Sc x Ga 2-x-y Fe y o 3 where x=0.3, y=0.85;

[0061] (2) Preparation of material rod: ball mill the mixture prepared in step (1) for 24 hours, dry at 100°C for 2 hours, pre-fire at 1300°C for 10 hours, and then grind again, and then put the ground powder into a long strip Sealed in a balloon, made into a rod shape under an isostatic pressure of 60-70 MPa, and then removed the balloon to obtain a rod;

[0062] (3) Sintering: Sinter the material rod prepared in step (2) in a high temperature furnace at 1350° C. for 15 hours to obtain a dense polycrystalline rod, which is used for crystal growth;

[0063] (4) Crystal growth: hang the feeding rod on the upper end of the light floating zone furnace with platinum wire, fix the feeding rod (using the seed crystal) on the seed crystal holder, install it at the lower en...

Embodiment 3

[0065] (1) Ingredients: Sc with a purity of not less than 99.99% 2 o3 , Fe 2 o 3 and Ga 2 o 3 The powder is prepared according to the stoichiometric ratio of Sc x Ga 2-x-y Fe y o 3 where x=0.1, y=0.95;

[0066] (2) Preparation of material rod: ball mill the mixture prepared in step (1) for 24 hours, dry at 100°C for 2 hours, pre-fire at 1300°C for 10 hours, and then grind again, and then put the ground powder into a long strip Sealed in a balloon, made into a rod shape under an isostatic pressure of 60-70 MPa, and then removed the balloon to obtain a rod;

[0067] (3) Sintering: Sinter the material rod obtained in step (2) at 1350° C. for 15 hours in a high-temperature furnace to obtain a dense polycrystalline rod, which is used for crystal growth;

[0068] (4) Crystal growth: Hang the feeding rod on the upper end of the laser floating zone furnace with a platinum wire, fix the feeding rod (using the seed crystal) on the seed crystal holder, install it on the lower en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap