Terahertz wave light-operated modulator and preparation method thereof

A modulator and terahertz technology, applied in the terahertz field, can solve the problems of high device manufacturing cost, complex processing, low operating frequency, etc., and achieve the effect of switching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

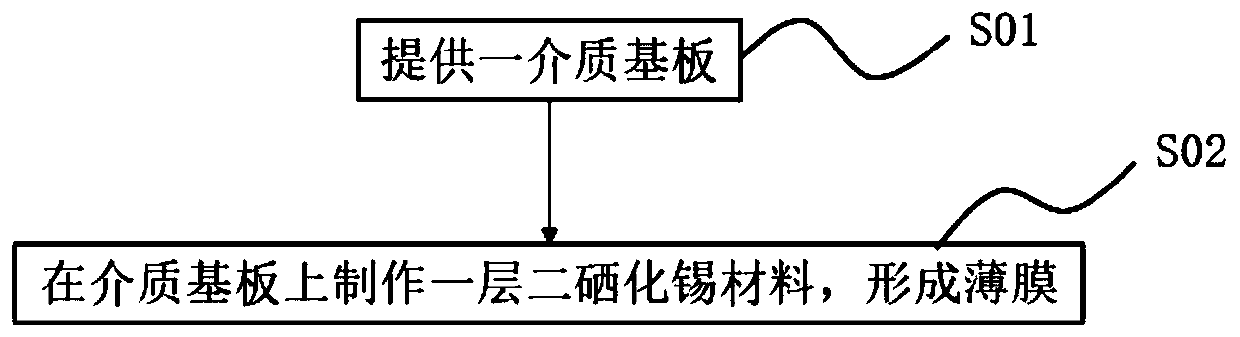

[0048] refer to figure 1 , the invention provides a preparation method of a terahertz wave optical control modulator, which mainly includes:

[0049] S01 , providing a dielectric substrate 10 .

[0050] The preparation process of the dielectric substrate 10 specifically includes:

[0051] Take a piece of high-resistance silicon wafer (such as 4 inches in size), clean it with hydrofluoric acid with a concentration between 4% and 8%, and soak it in hydrofluoric acid for 5min-10min to remove the oxide on the surface of the high-resistance silicon wafer ;

[0052] Then rinse the high-resistance silicon wafer with deionized water, dry it with nitrogen, and place it in a vacuum environment to prevent it from being oxidized by air again.

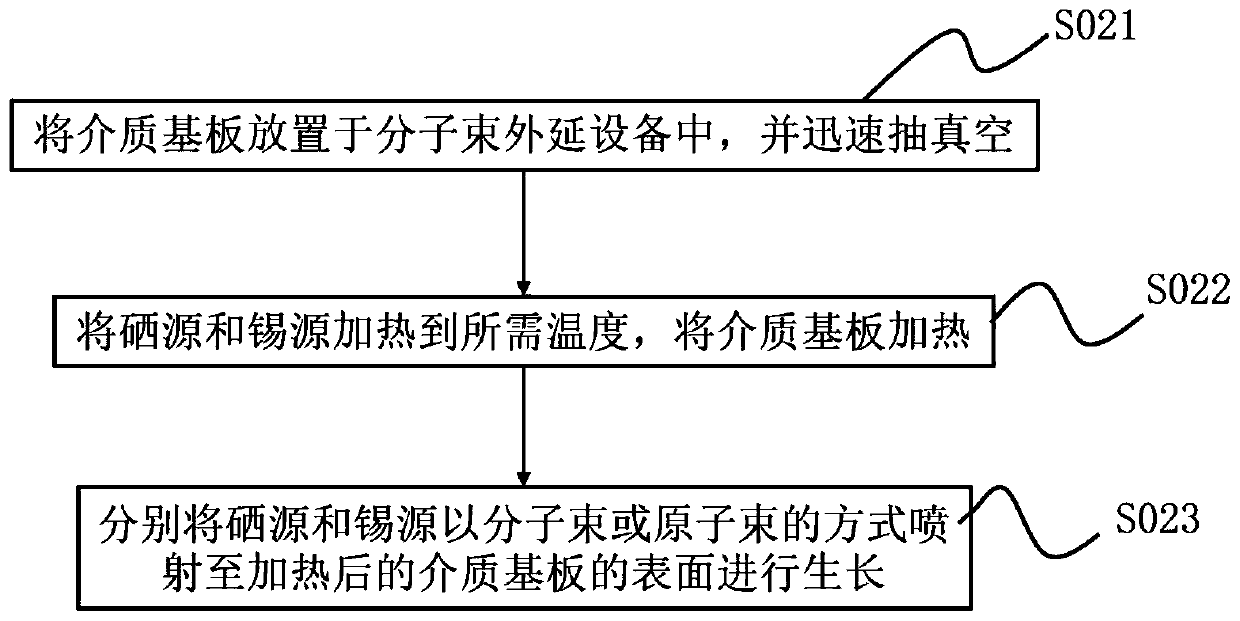

[0053] S02 , fabricating a layer of tin diselenide material on the dielectric substrate 10 to form a thin film 20 attached to the surface of the dielectric substrate 10 .

[0054] In this embodiment, the thin film 20 is grown by molecular beam ...

Embodiment 2

[0068] The tin diselenide material of the thin film 20 can be in several sheet structures standing on the surface of the dielectric substrate 10 .

[0069] Such as Figure 5 As shown, different from Embodiment 1, the steps of making a layer of tin diselenide material on the dielectric substrate 10 to form the thin film 20 in this embodiment include:

[0070] S021', prepare the nanoparticle of sheet-shaped tin diselenide.

[0071] This step can use the hot injection method, using the elemental selenium powder Se as the selenium source to obtain SnSe nanoparticles. When the amount of the Sn:Se precursor added is 1:2, the SnSe with a flaky shape can be generated. 2 of nanoparticles.

[0072] Preferably, the step S021' of preparing flake-shaped nanoparticles of tin diselenide specifically includes:

[0073] S0211', mix 1.152mmol selenium powder with 3ml oleylamine (OLA) and 1ml n-dodecanethiol, stir and heat to 60°C on a magnetic stirrer, so that Se is fully dissolved in OLA to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com