Metal component thermal mechanical fatigue life prediction method based on different constraint conditions

A technology of thermomechanical fatigue and constraint conditions, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of lack of applicability of fatigue life, Non-conservative or too conservative and other issues, to achieve the effect of high applicability, good applicability, and accurate service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment is to predict the life of the cast aluminum material for the piston under the thermomechanical fatigue condition, and the prediction process is as follows figure 1 As shown, the specific process is as follows:

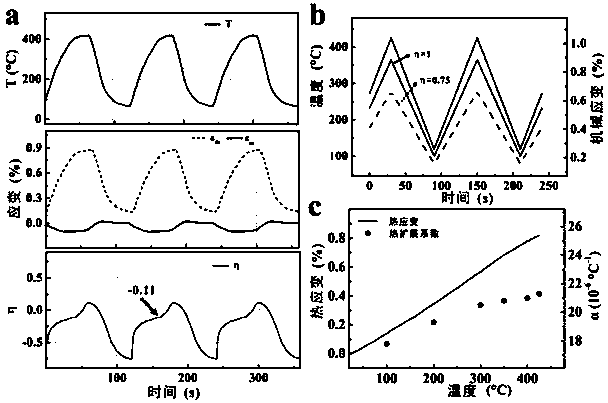

[0041] First, the cast aluminum material is taken from the diesel engine piston. According to the working conditions, the load spectrum of the temperature, thermal strain, mechanical strain and constraint coefficient η of the most vulnerable part of the piston component is drawn with time. The constraint ratio in dangerous state is -0.11, such as figure 2 (a).

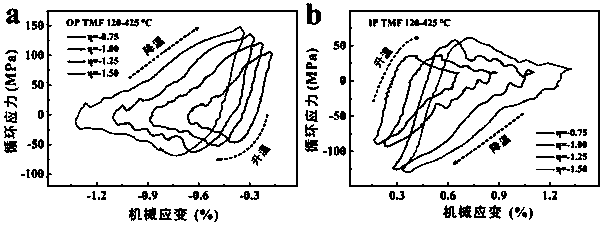

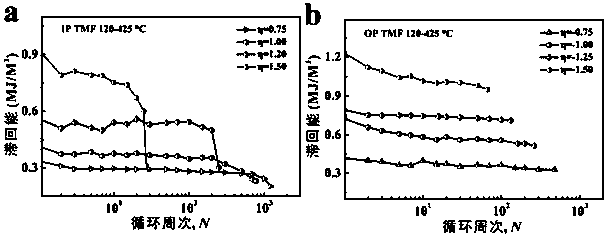

[0042] Second, according to the actual working conditions, the accelerated thermomechanical fatigue experiment under constraint is carried out. The loading conditions are as follows: figure 2 (b) shown. The temperature range of the test cycle is 120-425 ° C, and the loading constraint coefficient is from -1.5 to 1.5 (in-phase: η = -0.75, -1.0, -1.25, -1.5; anti-phase: η = 0.75, 1.0, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com