Lithium-ion battery silicon oxide composite negative electrode material and preparation method thereof, lithium-ion battery

A lithium-ion battery, silicon oxide technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of poor conductivity of silicon-based materials, easy powdering and falling off of active materials, and affecting battery life. Achieve the effect of improving coating uniformity, improving electrical conductivity, and improving contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

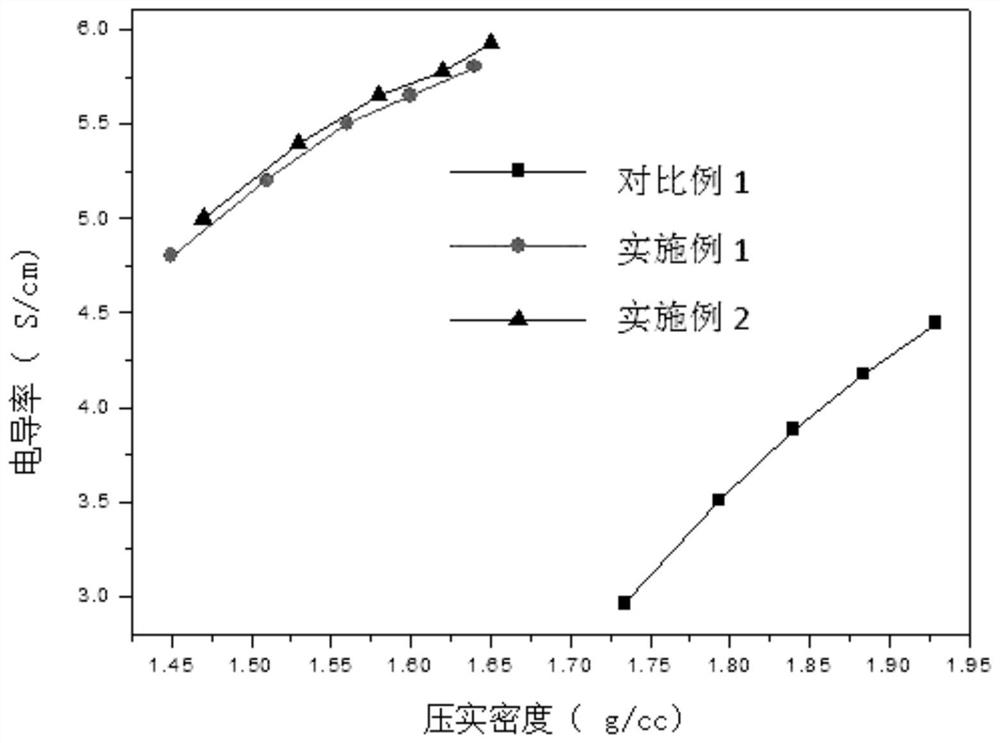

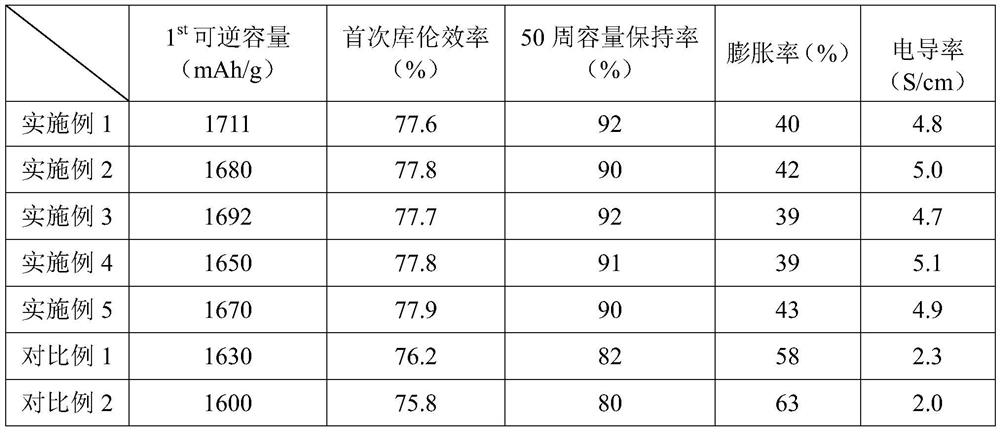

Embodiment 1

[0026] Take 2 kg of SiO powder with a median particle size D50 of 10 μm, put it into a rotary furnace, pass in nitrogen gas to exhaust oxygen, and set the flow rate at 10 L / min. After the oxygen exhaust is completed, heat up and roast. 10°C / min, rotation speed 1rpm. After the above reaction is completed, lower the roasting temperature to 750°C, cool down naturally in a nitrogen atmosphere, and hold for 1 hour. When the temperature is stable, feed acetylene gas with a flow rate of 3 L / min, and keep the temperature constant for 3 hours. After the reaction is completed, turn off the acetylene gas, raise the temperature to 1200°C, the heating rate is 10°C / min, and the holding time is 1h, then inject methane gas and hydrogen gas, set the flow rate of methane gas to 3L / min, and the flow rate of hydrogen gas to 1L / min, keep the temperature constant and ventilate for 5h, turn off the hydrogen and methane after the reaction is complete, and cool down naturally under the nitrogen atmos...

Embodiment 2

[0028] Take 3 kg of SiO powder with a median particle size D50 of 6 μm, put it into a rotary furnace, pass in nitrogen gas to exhaust oxygen, and set the flow rate at 10 L / min. After the oxygen exhaust is completed, heat up and roast. 10°C / min, rotation speed 1rpm. After the above reaction is completed, lower the roasting temperature to 800°C, lower the temperature naturally under a nitrogen atmosphere, and hold the temperature for 1 hour. When the temperature is stable, feed ethanol steam, set the flow rate to 2L / min, and keep the temperature constant for 3 hours. After the reaction is completed, turn off the acetylene gas, raise the temperature to 1200°C, the heating rate is 10°C / min, and the holding time is 1h, then inject methane gas and hydrogen gas, set the flow rate of methane gas to 3L / min, and the flow rate of hydrogen gas to 1L / min, keep the temperature constant and ventilate for 5h, turn off the hydrogen and methane after the reaction is complete, and cool down nat...

Embodiment 3

[0030] Take 4 kg of SiO powder with a median particle size D50 of 8 μm, put it into a rotary furnace, pass in nitrogen gas to exhaust oxygen, and set the flow rate at 10 L / min. After the oxygen exhaust is completed, heat up and roast. 10°C / min, rotation speed 1rpm. After the above reaction is completed, feed methane gas, set the flow rate to 4L / min, keep the temperature and ventilate for 3h, turn off the methane gas after the reaction is completed, raise the temperature to 1200°C, the heating rate is 10°C / min, and the holding time is 1h. Then inject methane gas and hydrogen gas, set the flow rate of methane gas to 4L / min, and the flow rate of hydrogen gas to 1L / min, keep the temperature and ventilate for 5h, turn off the hydrogen and methane gas after the reaction is complete, and cool down naturally under nitrogen atmosphere. After complete cooling, the materials are taken out for crushing, sieving, and demagnetization to obtain a silicon oxide composite negative electrode ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com