Preparation method of perovskite quantum dot

A quantum dot and perovskite technology, which is applied in the field of preparation of CsPb1-xZnxBr3 perovskite quantum dots, can solve the problems of long reaction time, low ion exchange efficiency, long stirring time, etc., and achieves simple steps, low cost, and equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

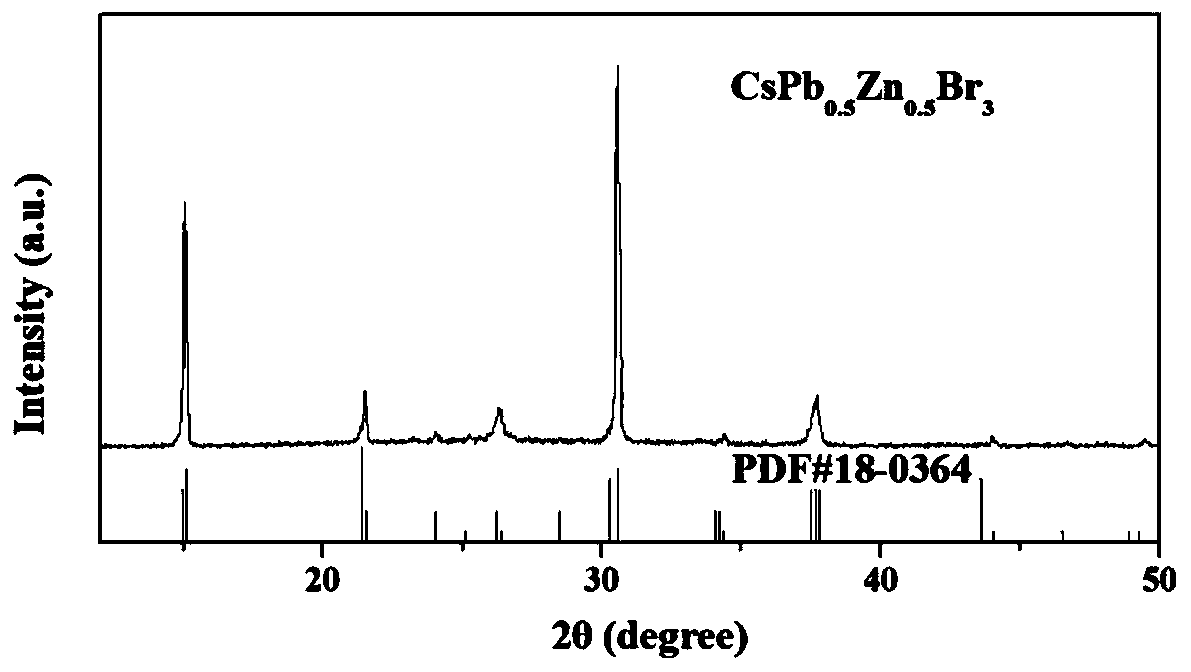

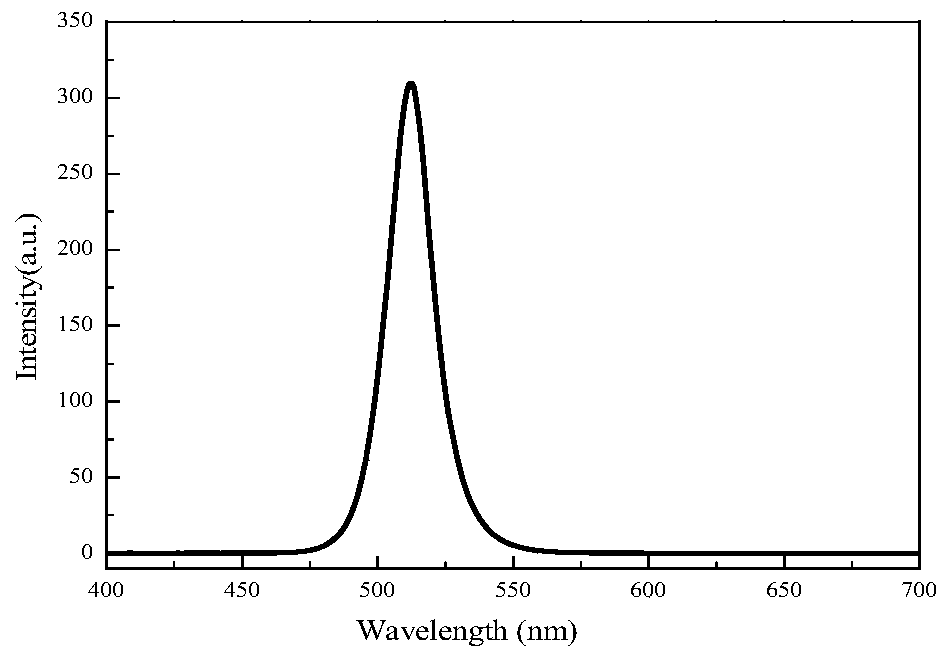

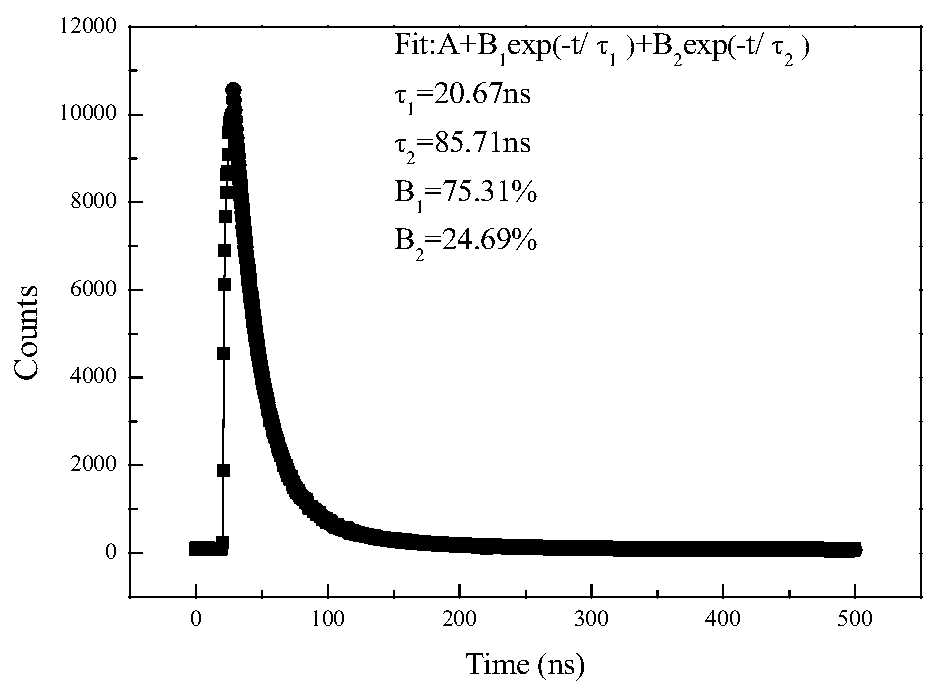

[0030] A CsPb 1-x Zn x Br 3 The preparation method of perovskite quantum dots specifically comprises the following steps:

[0031] (1) First weigh 0.164g of Cs according to the ratio of Cs:Pb:Zn=2:1:1 2 CO 3 , 0.185g of PbBr 2 and 0.113g of ZnBr 2 Mix and add in the three-necked flask, then inject 2.5ml oleic acid (OA), 2.5ml oleylamine (OLA) and 10ml of 1-octadecene (ODE) with a pipette gun, and utilize nitrogen to blow out the air in the three-necked flask to make The reaction is in a nitrogen protective atmosphere, heated to 120°C, and magnetically stirred for 15 minutes. Immediately after the reaction is completed, an ice-water bath is carried out to synthesize CsPb 1-x Zn x Br 3 Perovskite quantum dots;

[0032] (2) to the CsPb after generating according to above-mentioned steps (1) 1-x Zn x Br 3 The perovskite quantum dots are separated, purified and stored. The above synthesized perovskite quantum dot solution is centrifuged at a speed of 8000rpm for 10min, ...

Embodiment 2

[0038] A CsPb 1-x Zn x Br 3 The preparation method of perovskite quantum dots specifically comprises the following steps:

[0039] (1) The cesium source Cs 2 CO 3 , lead source PbBr 2 and zinc source ZnBr 2 Form mixture after mixing; Wherein the atomic ratio of Cs, Pb, Zn in cesium source, lead source and zinc source is Cs:Pb:Zn=1:0.9:0.1;

[0040] (2) Add oleic acid (OA), oleylamine (OLA) and 1-octadecene (ODE) to the mixture to form a suspension, wherein the zinc source, oleic acid, oleylamine and 1-octadecene The molar volume ratio is 0.5mmol:2ml:2ml:8ml;

[0041] (3) The suspension is heated and reacted in a nitrogen protective atmosphere, and magnetic stirring is performed at the same time. After the reaction is completed, the reaction solution is cooled in an ice-water bath to generate CsPb 1-x Zn x Br 3 Perovskite quantum dots, wherein the temperature of the heating reaction is 90° C., and the time is 15 minutes.

[0042] (4) will contain CsPb 1-x Zn x Br ...

Embodiment 3

[0044] A CsPb 1-x Zn x Br 3 The preparation method of perovskite quantum dots specifically comprises the following steps:

[0045] (1) The cesium source Cs 2 CO 3 , lead source PbBr 2 and zinc source ZnBr 2 Form a mixture after mixing; Wherein the atomic ratio of Cs, Pb, Zn in cesium source, lead source and zinc source is Cs:Pb:Zn=1:0.1:0.9;

[0046] (2) Add oleic acid (OA), oleylamine (OLA) and 1-octadecene (ODE) to the mixture to form a suspension, wherein the zinc source, oleic acid, oleylamine and 1-octadecene The molar volume ratio is 0.5mmol:3ml:3ml:12ml;

[0047] (3) The suspension is heated and reacted in a nitrogen protective atmosphere, and magnetic stirring is performed at the same time. After the reaction is completed, the reaction solution is cooled in an ice-water bath to generate CsPb 1-x Zn x Br 3 Perovskite quantum dots, wherein the temperature of the heating reaction is 120° C., and the time is 20 minutes.

[0048] (4) will contain CsPb 1-x Zn x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com